Method for preparing SGOI or GOI by utilizing C adulteration SiGe preparing layer

A technology for modulating layer and doping concentration, which is applied in the field of semiconductor material preparation, and can solve problems such as defects, affecting SGOI or GOI performance, lattice mismatch, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Such as Figure 1 ~ Figure 6 As shown, this embodiment provides a method for preparing SGOI or GOI by using a C-doped SiGe modulation layer, which at least includes the steps:

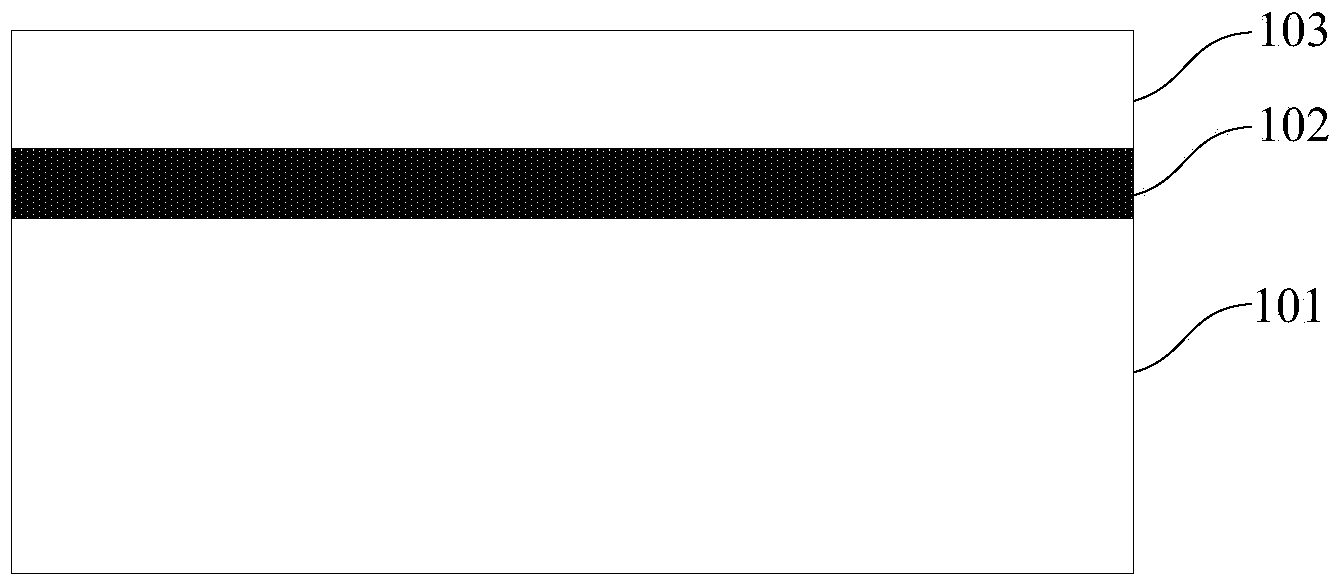

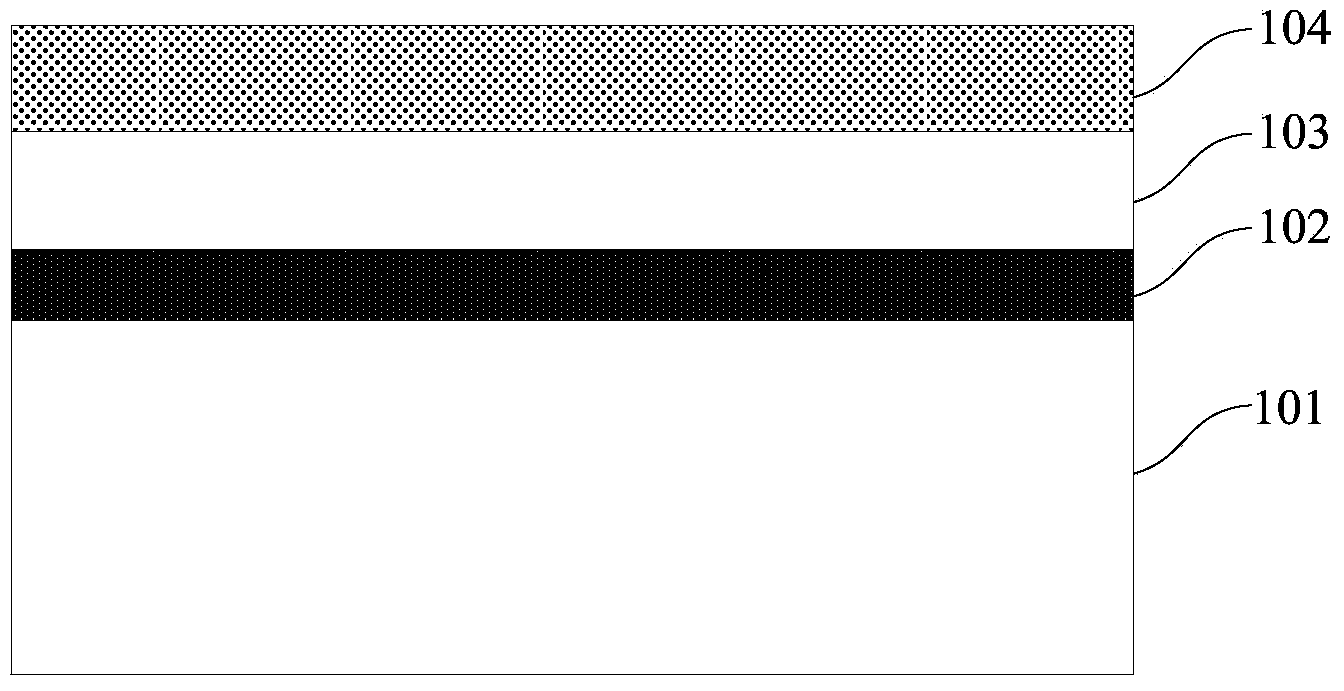

[0041] Such as Figure 1 ~ Figure 2 As shown, step 1) is first performed to provide an SOI substrate including a silicon substrate 101, a buried oxide layer 102 and a top silicon layer 103, and a C-doped SiGe modulation layer 104 is formed on the surface of the top silicon layer 103.

[0042] As an example, in the C-doped SiGe modulation layer 104, the doping concentration of C is not less than 1E20 / cm 3 . In this embodiment, in the C-doped SiGe modulation layer 104, the doping concentration of C is a constant value. Specifically, in the C-doped SiGe modulation layer 104, the doping concentration of C is 3E20 / cm 3 .

[0043] As an example, the thickness of the C-doped SiGe modulation layer 104 is not less than 20 nm and not greater than its critical thickness. In this embodiment, the thickness of the...

Embodiment 2

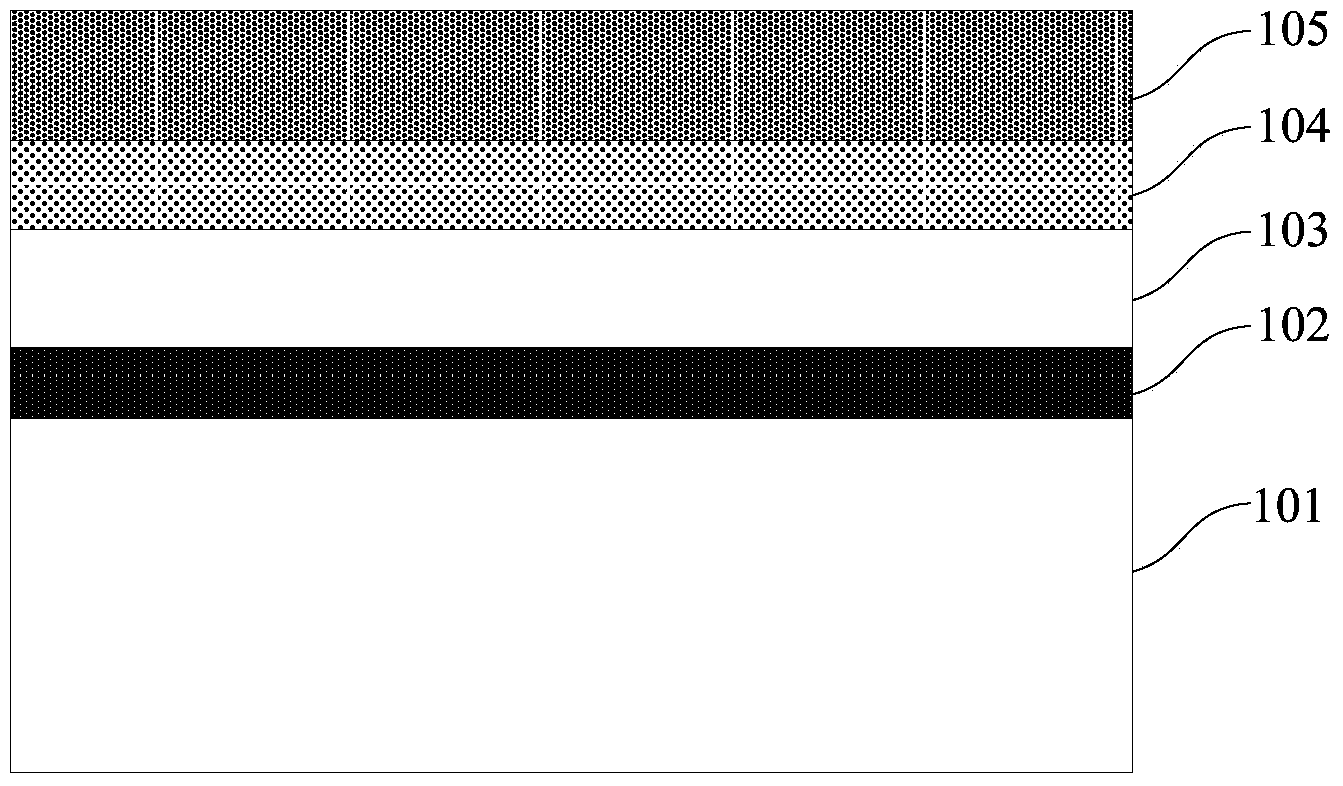

[0056] Such as Figure 1 ~ Figure 6 As shown, this embodiment provides a method for preparing SGOI or GOI using a C-doped SiGe modulation layer. The basic steps are the same as those in Embodiment 1. In the C-doped SiGe modulation layer 104, the doping concentration of C is not Instead, it gradually decreases from bottom to top, that is, the C concentration near the top silicon layer 103 is high, and the C concentration near the SiGe material layer 105 is low, so that the top silicon layer 103 of SOI and the epitaxial SiGe material can be better adjusted The lattice mismatch between the layers 105 reduces the occurrence of defects.

[0057] As described above, the present invention provides a method for preparing SGOI or GOI using a C-doped SiGe modulation layer, which includes the steps: 1) Provide an SOI substrate including a silicon substrate, a buried oxide layer and a top silicon layer, and A C-doped SiGe modulation layer is formed on the surface of the silicon layer; 2) a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com