LED lamp bead

A technology of LED lamp beads and accommodating cavity, which is applied in electrical components, electric solid-state devices, circuits, etc., can solve the problems of small heat dissipation area, color drift of LED lamp beads, and precipitation of phosphor powder, and achieve the effect of thin thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

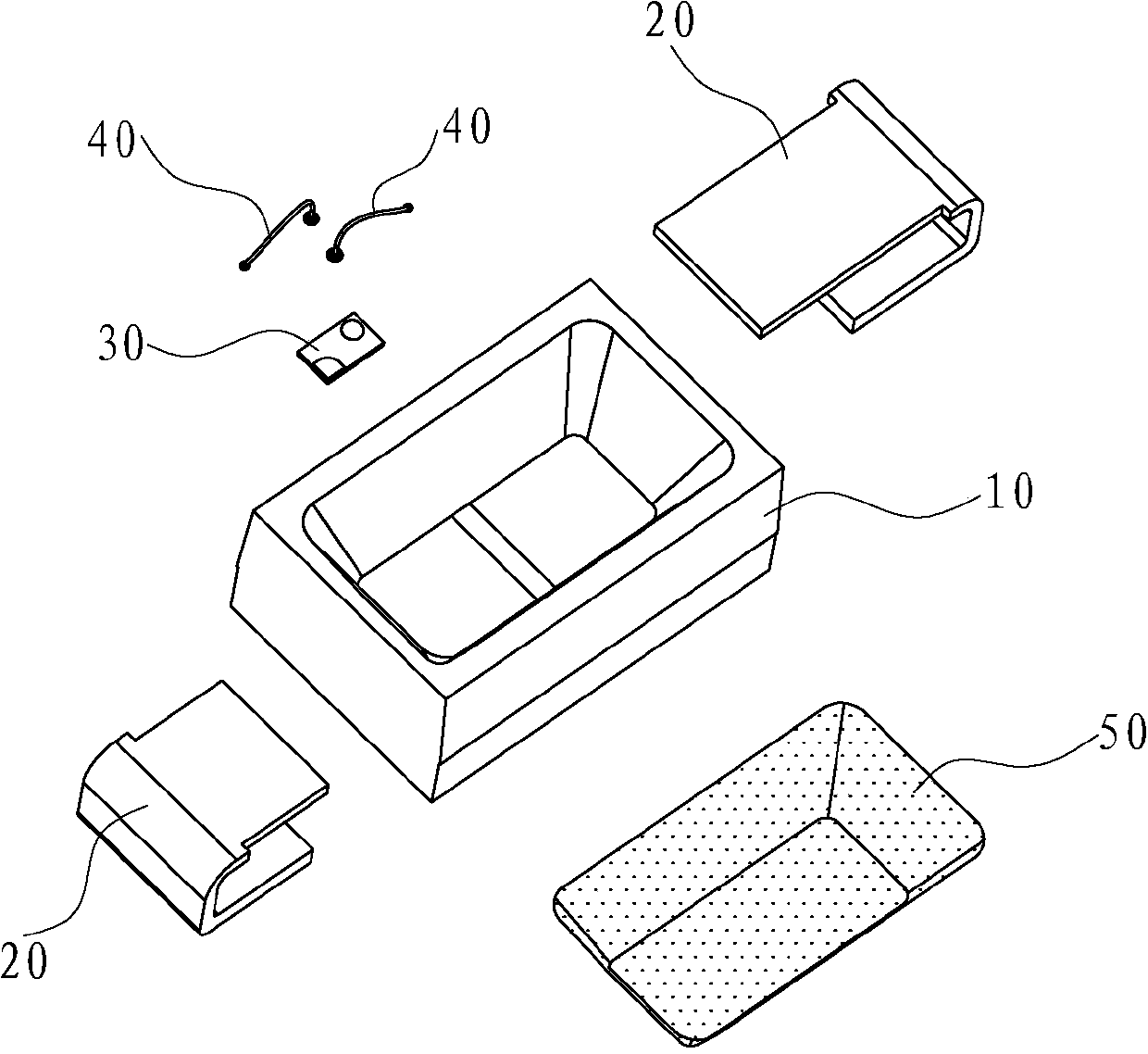

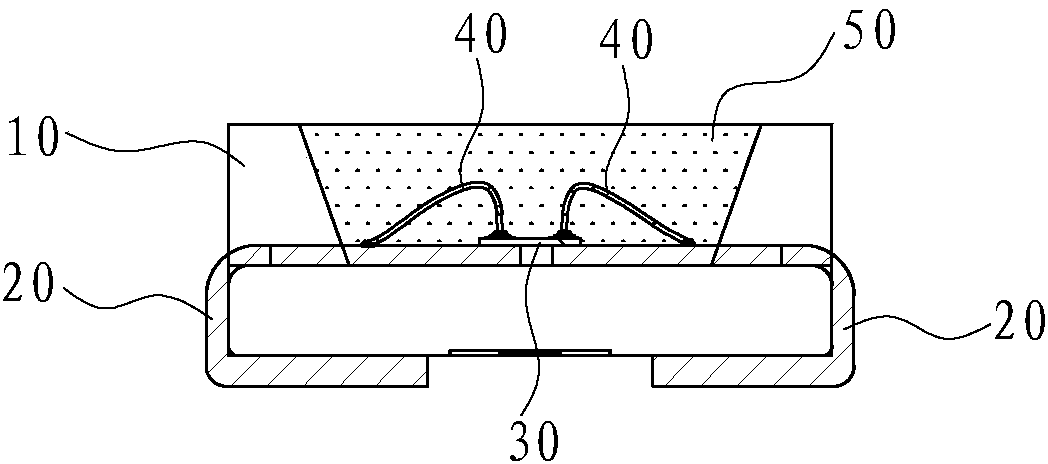

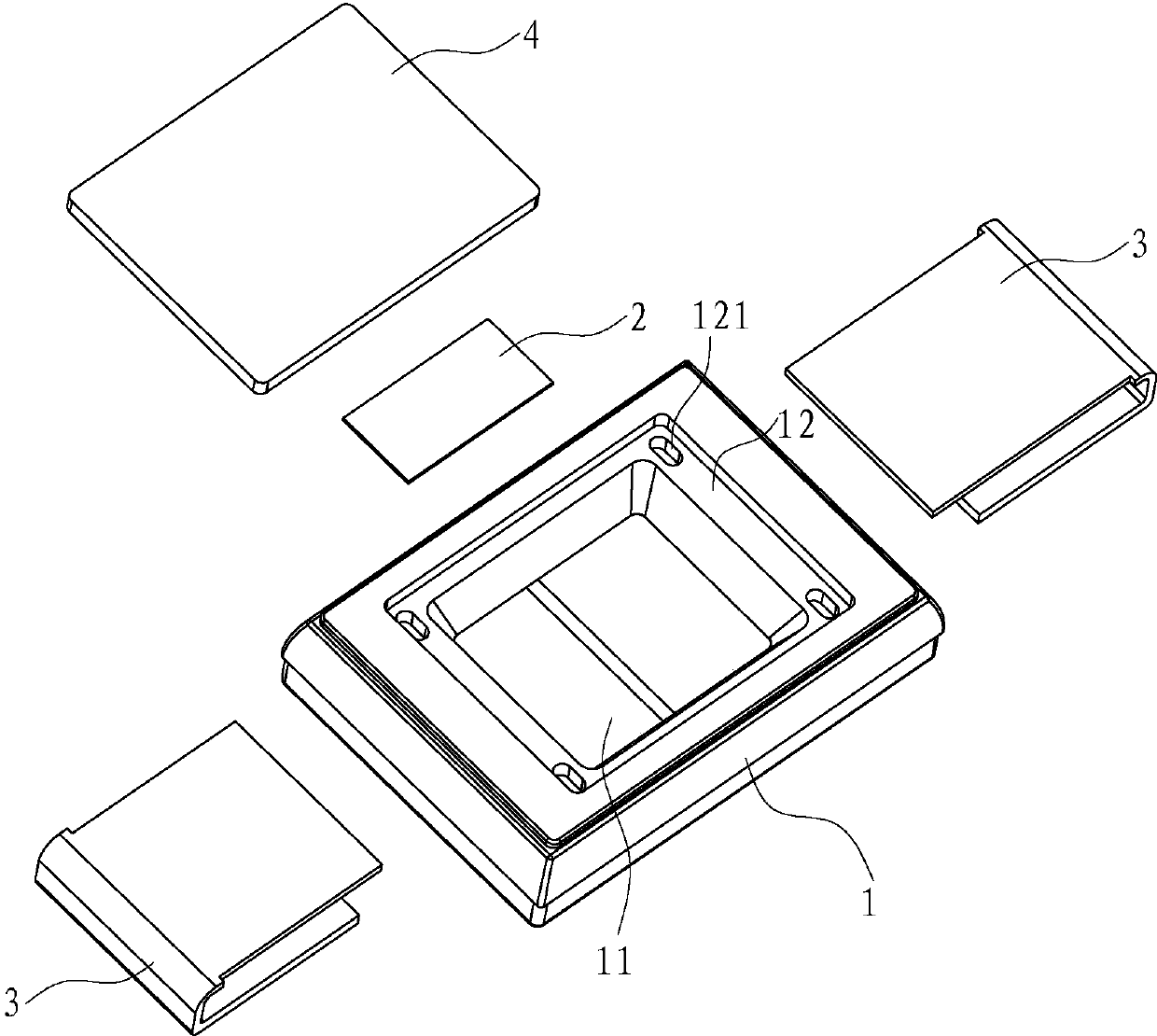

[0024] refer to Figure 3 to Figure 5 As shown, an LED lamp bead disclosed by the present invention includes a heat-conducting housing 1 provided with an accommodating cavity 11 , a flip chip 2 , two pins 3 and a fluorescent sheet 4 .

[0025] The two pins 3 are respectively embedded in the accommodating chamber 11 of the heat-conducting shell 1, and the bottom of the accommodating chamber 11 is sealed. The two pins 3 are respectively located on both sides of the heat-conducting shell 1. as the negative pole.

[0026] The flip chip 2 is mounted on the two pins 3 and is electrically connected to the two pins 3 respectively, that is, the flip chip 2 is electrically connected to the positive pin 3 and the negative pin 3 respectively, and the flip chip 2 is located in the container Put it in chamber 11.

[0027] The flip-chip 2 is mounted on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com