Battery pack

A technology for battery packs and single cells, applied to battery pack components, circuits, electrical components, etc., can solve the problems affecting the performance and service life of the battery, the contact between the conductive strip and the surface of the pole is not tight, and the assembly process is not fast enough. problems, to achieve the effect of increasing conductivity, firm and reliable connection, and neat wiring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

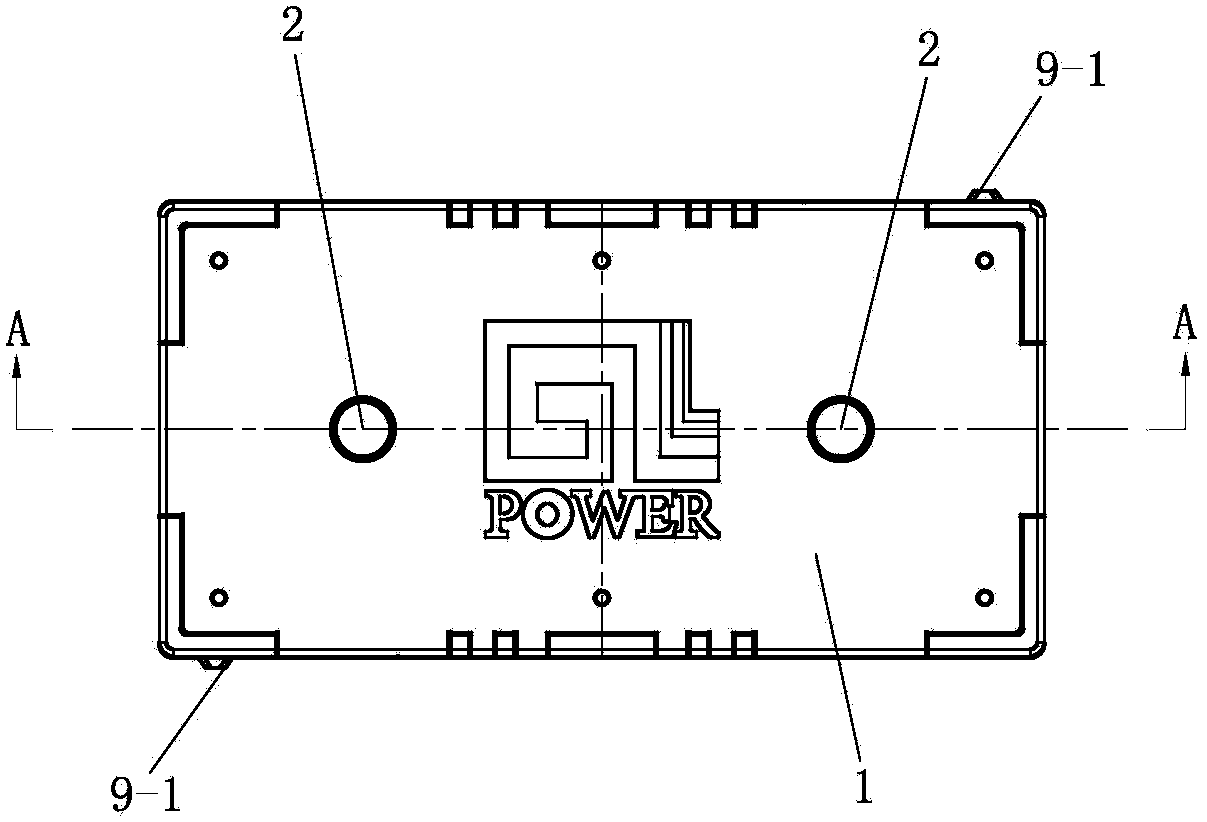

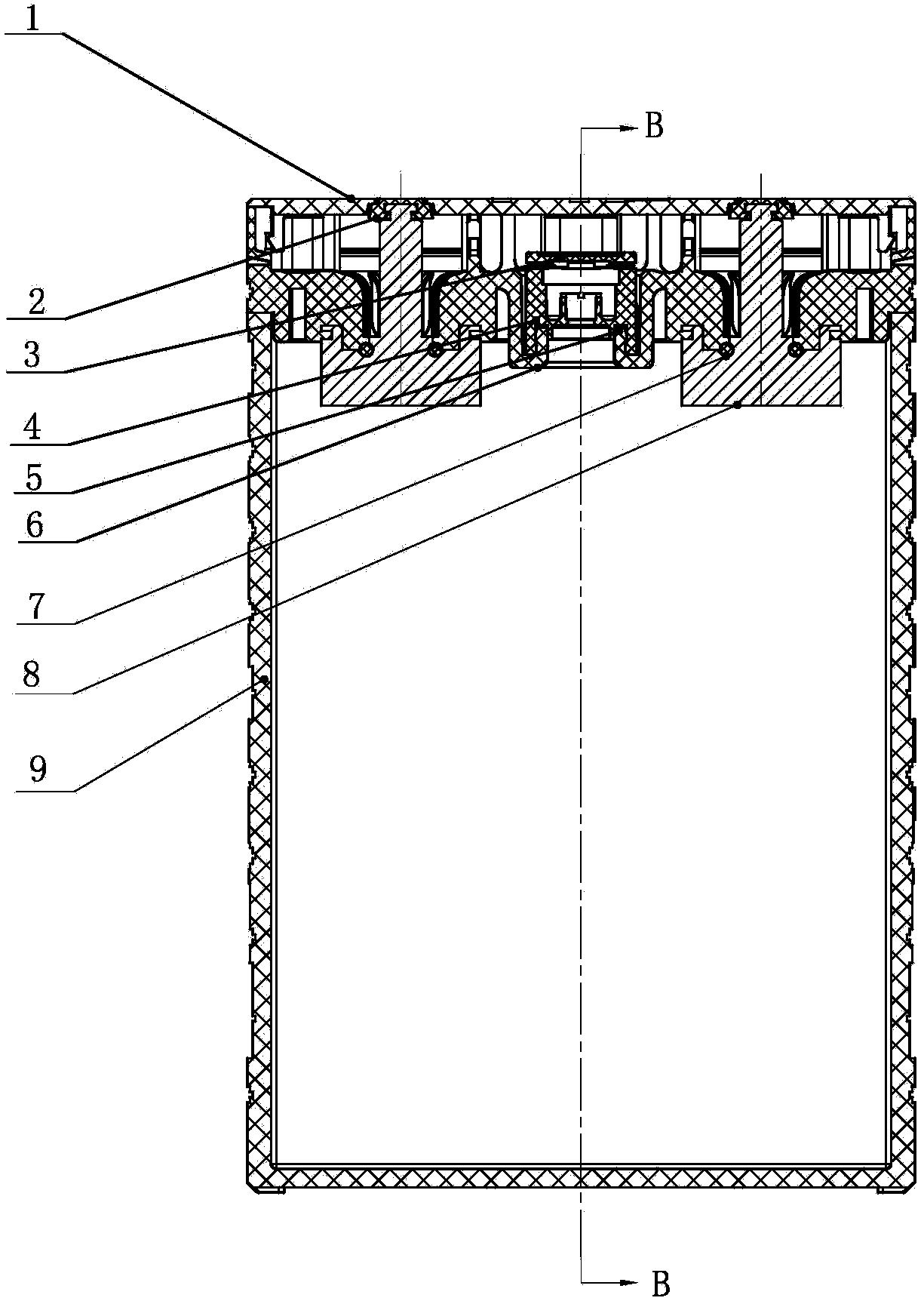

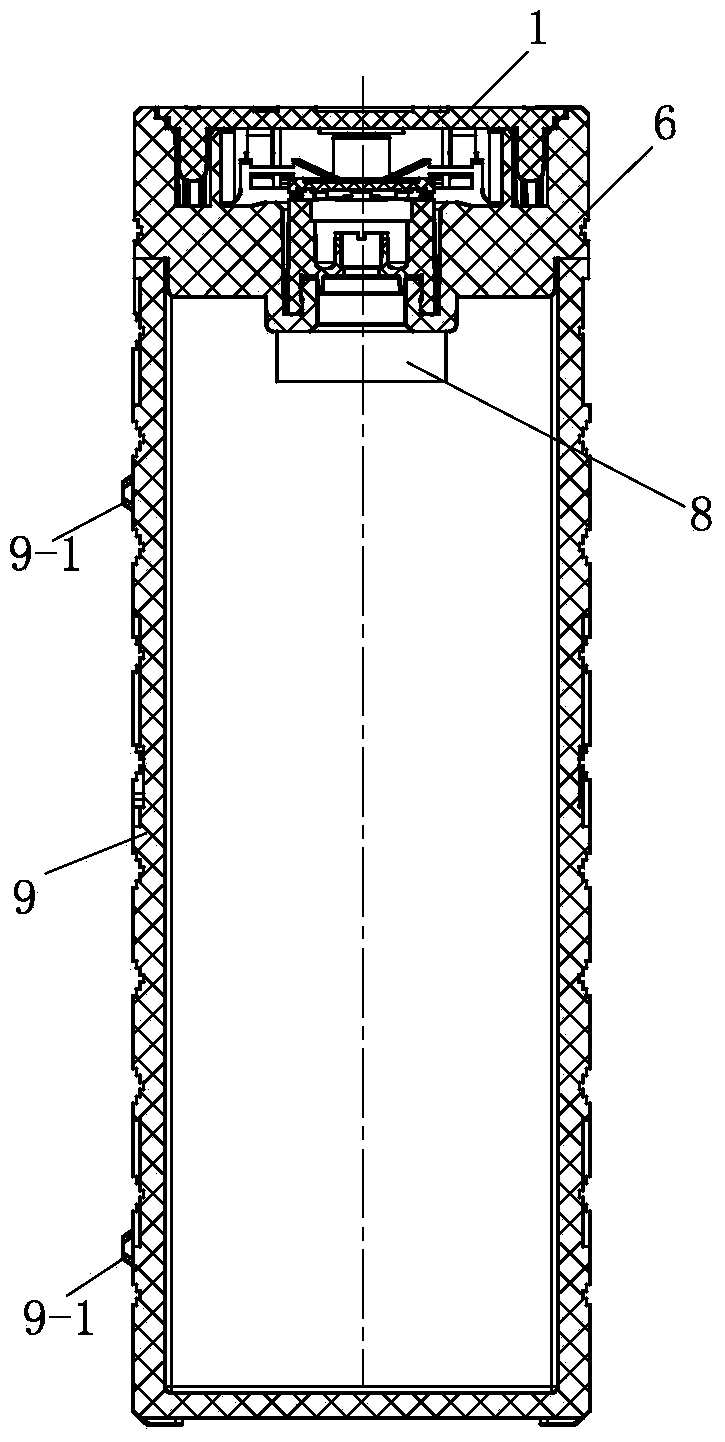

[0048] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0049] Such as Figure 1-3 As shown, the single battery of this embodiment includes a square-shaped plastic casing 9 containing battery components and having an upper opening, which is sealed with a heat sealing cover 6. A safety valve 4 is installed in the middle of the heat-sealing cover 6, and an O-ring 5 is inserted into the contact between the two. The outer end of the safety valve 4 is also covered with a decorative cover 3.

[0050] The heat sealing cover 6 is equipped with two poles 8 namely positive and negative poles. The positive and negative poles and the heat sealing cover are integrated, and the positive pole and the negative pole are symmetrically arranged on both sides of the safety valve. See Figure 19-20 , The longitudinal section of the pole 8 is in the shape of ⊥, the inner section 8-1 is cube-shaped, and the vertical sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com