Marx generator with compact structure

A compact and generator technology, applied in the field of Marx generators with compact structure, can solve the problems of complicated operation, reduced loop inductance, large footprint, etc., and achieve the effect of reducing the volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

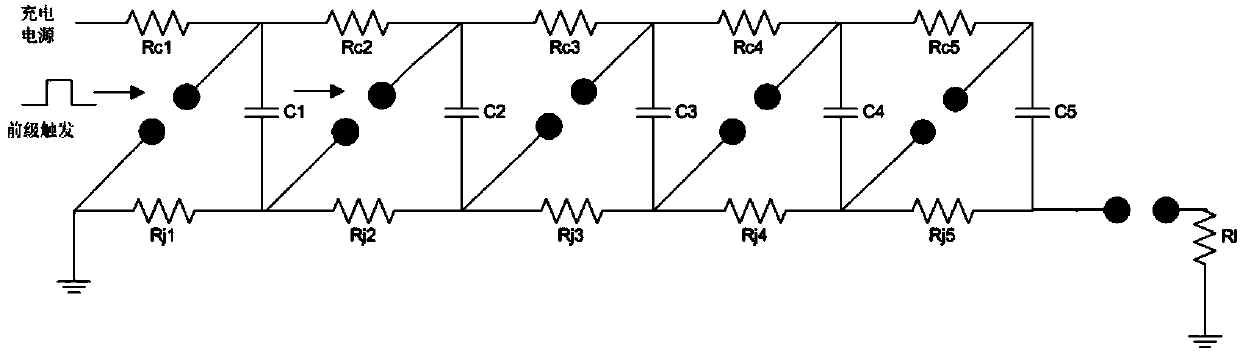

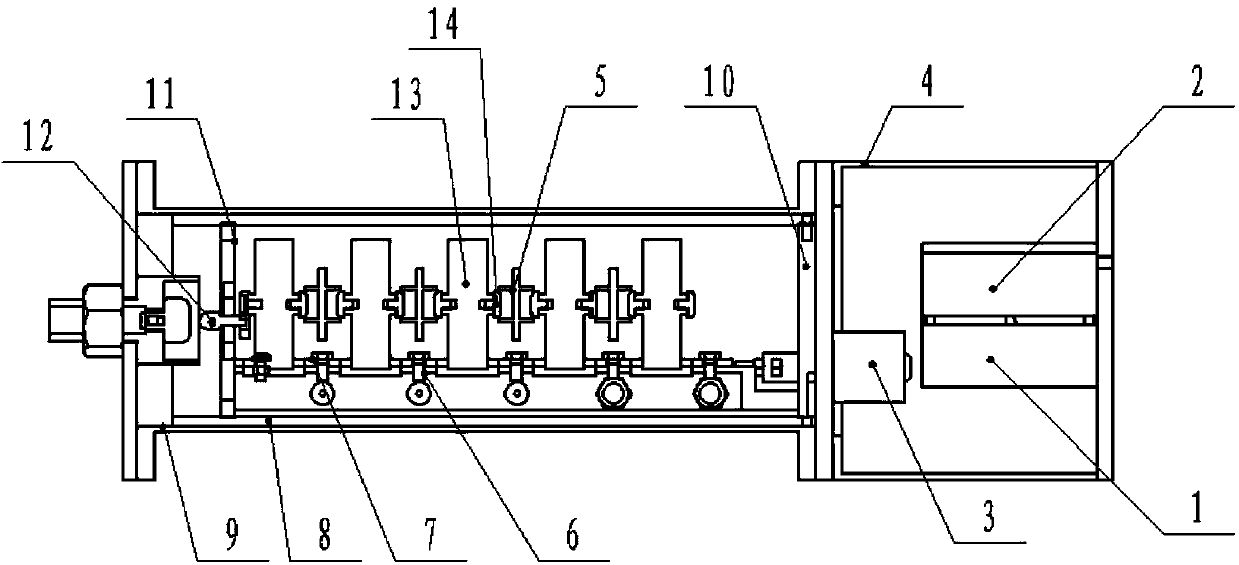

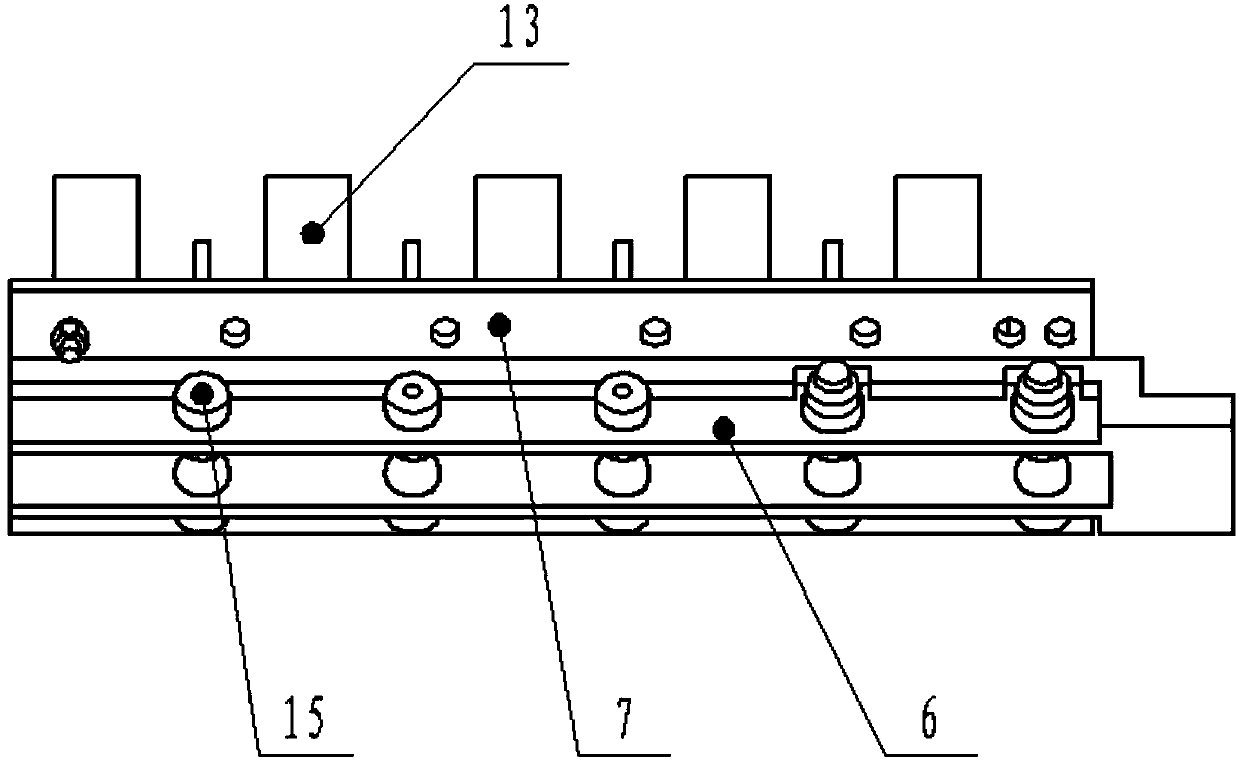

[0025] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

[0026] The proposed compact Marx generator of embodiment, the circuit principle of Marx generator sees figure 1 . The charging power source 1 and the pre-stage trigger source 2 are placed in the metal cylinder 4 connected to the front end of the outer cylinder 9, the insulator 5 between the capacitors is placed between the capacitors 13, and the gas spark switch electrode 15 is installed on the circle of the switch track 6 arranged in a straight line. In the hole, the capacitor 13 is fixed on the capacitor support plate 7 through the capacitor switch connection plate 14 . The inner cylinder 8 is connected to the switch track 6 through the ground insulating plate 10 , and connected to the output positioning electrode 12 through the output insulating plate 11 .

[0027] The charging power source 1 and the pre-stage trigger source 2 are integrated and installed in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com