Ceramic package and manufacturing method thereof

A technology for ceramic shells and manufacturing methods, which is applied in the direction of electrical equipment shells/cabinets/drawers, electrical components, etc., which can solve the problems of high difficulty in assembling ceramic shells, and achieve good appearance effects, reliable assembly, and excellent heat dissipation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be emphasized that the following description is only exemplary and not intended to limit the scope of the invention and its application.

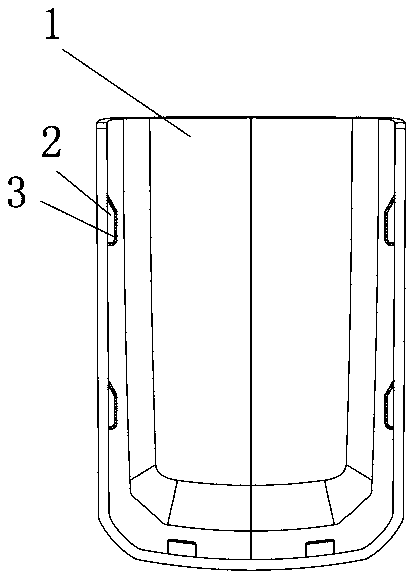

[0021] refer to figure 1 , in some embodiments, a ceramic housing includes a ceramic structural part 1 and an assembly (not shown), the ceramic structural part has at least one buckle part 2, and wraps on at least one buckle part 2 Covered with a button covering part 3, the button covering part 3 is colloidal material. The rubber material can be silica gel, plastic soft rubber such as TPU soft rubber, etc.

[0022] The buckle part 2 is not closely fitted to the assembly body, and the gap is filled by the buckle covering part 3 . The ceramic structural member part 1 and the buckle covering part 3 can be combined through the slot of the buckle part 2 with glue. Snap parts and other assembly structures act ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com