Closed type composite cooling system

A compound cooling and closed technology, which is applied in the direction of cooling/ventilation/heating transformation, can solve the problems of land occupation, large amount, fluid resistance, etc., and achieve the effect of high cost, cost reduction and consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

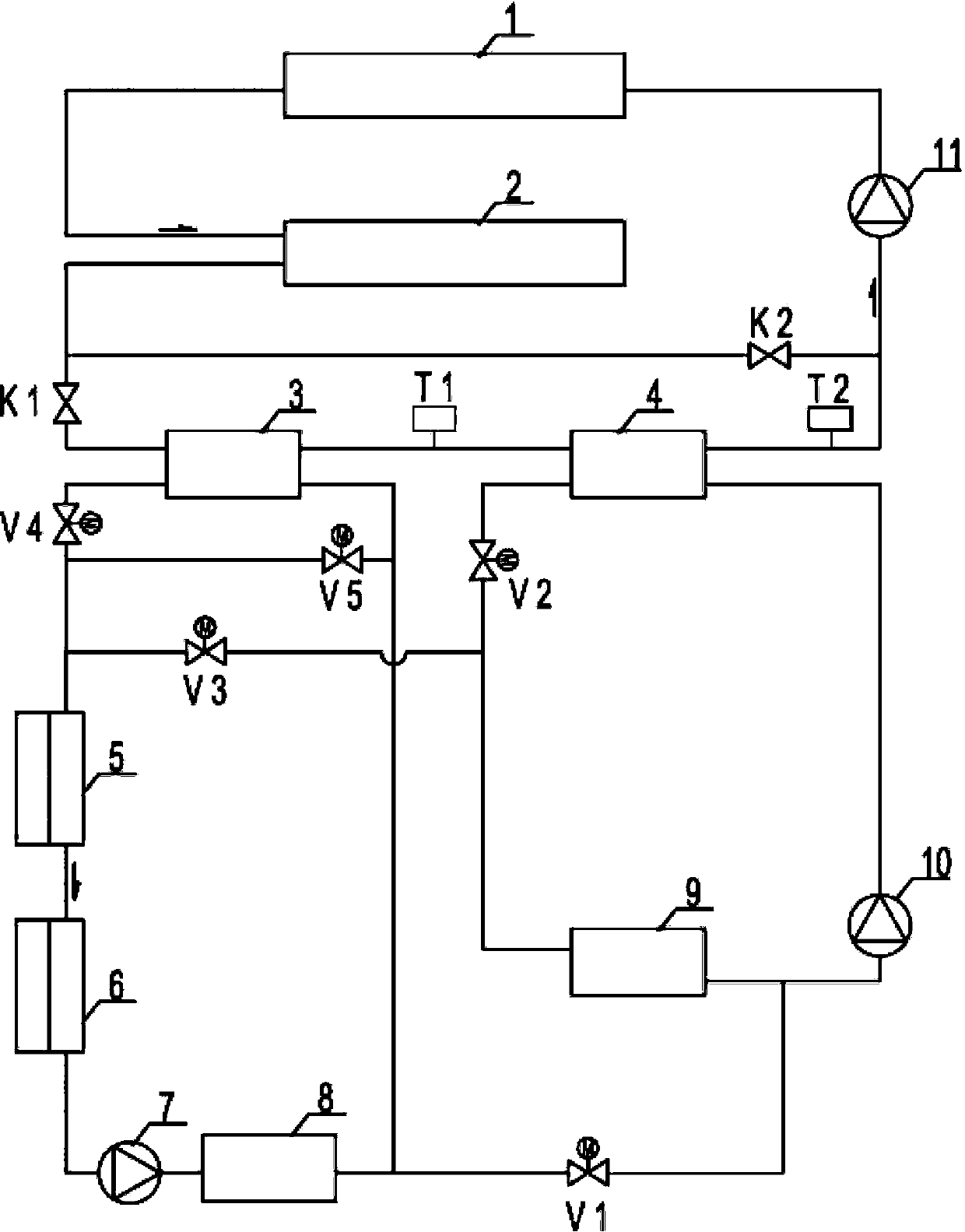

[0023] Such as figure 1 As shown, a closed composite cooling system includes a cooled device 1, an air cooler 2, a first plate heat exchanger 3, a second plate heat exchanger 4, a first chiller 5, a second chiller 6, The first cold pump (fixed frequency) 7, buffer tank 8, inclined temperature layer cold storage tank 9, the second cold pump (frequency conversion) 10, cooling water pump 11;

[0024] The cooled device 1, air cooler 2, valve K1, first plate heat exchanger 3, second plate heat exchanger 4 and cooling water pump 11 are sequentially connected to form a circulation loop, and the circulation loop is connected in parallel with a first bypass valve K2 ;

[0025] The hot side of the first plate heat exchanger 3 and the hot side of the second plate heat exchanger 4 are connected in series in a circulation loop;

[0026] The first chiller 5, the second chiller 6, the first cold pump (fixed frequency) 7, the buffer tank 8, the valve V1, the ramp type cold storage tank 9 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com