Peak-clipping closed circulating pure water cooling system

A cooling system and closed technology, which is applied in the field of closed circulating pure water cooling system, can solve the problems of occupying land, a large amount, and fluid resistance, and achieve the effects of high cost, cost reduction, and consumption reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

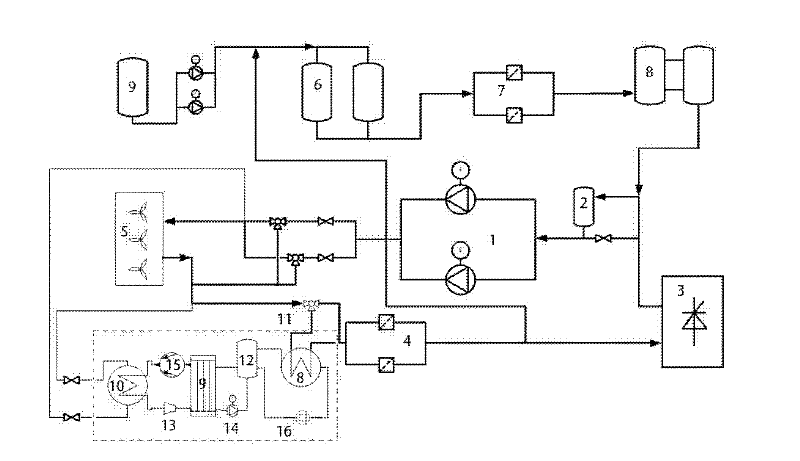

[0020] Such as figure 2 As shown, a peak-shaving closed circulating pure water cooling system includes a closed circulating pure water cooling system and an air cooler, a main circulating water pump 1, a degassing tank 2, a diverter valve 3, a filter 4 and an air cooling system. The air cooler 5 is connected into the main circuit, and the air cooler 5 is connected in the main circuit through a parallel three-way valve, so that the medium in the main circuit can enter the next device without passing through the air cooler 5. The water treatment branch and the main circuit are merged at the inlet of the diverter valve 3. The water treatment branch includes an ion exchanger 6, a precision filter 7 and an expansion tank 8. The automatic water replenishment system includes a raw water tank 9 connected in sequence, an automatic water replenishment The pump and the automatic water supply system are connected to the ion exchanger 6, and also include an auxiliary circulation circuit a...

Embodiment 2

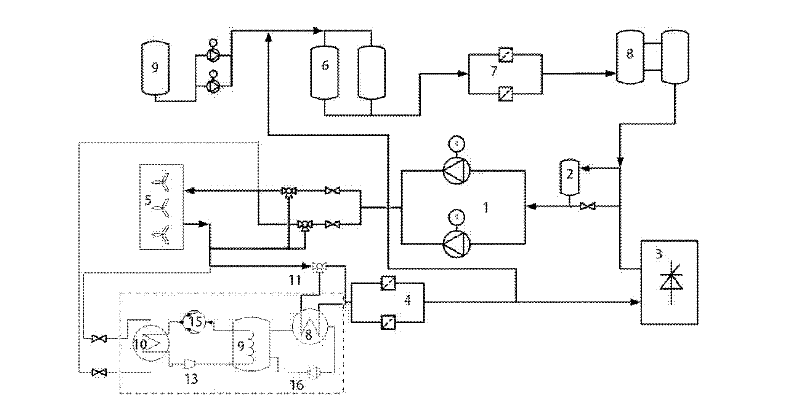

[0027] Such as image 3 As shown, a peak-shaving closed circulating pure water cooling system includes a closed circulating pure water cooling system and an air cooler, a main circulating water pump 1, a degassing tank 2, a diverter valve 3, a filter 4 and an air cooling system. The air cooler 5 is connected into the main circuit, and the air cooler 5 is connected in the main circuit through a parallel three-way valve, so that the medium in the main circuit can enter the next device without passing through the air cooler 5. The water treatment branch and the main circuit are merged at the inlet of the diverter valve 3. The water treatment branch includes an ion exchanger 6, a precision filter 7 and an expansion tank 8. The automatic water replenishment system includes a raw water tank 9 connected in sequence, an automatic water replenishment The pump and the automatic water supply system are connected to the ion exchanger 6, and also include an auxiliary circulation circuit an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com