A two-stage gas washing method

一种气体、氢气的技术,应用在分离方法、气体处理、制造可燃气体等方向,能够解决温差消耗、能量处理成本高昂等问题,达到能量消耗低的效果

Active Publication Date: 2013-12-25

NESTE OIL OY

View PDF10 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Huge temperature differences between process stages consume a lot of energy and make processing costly

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 3

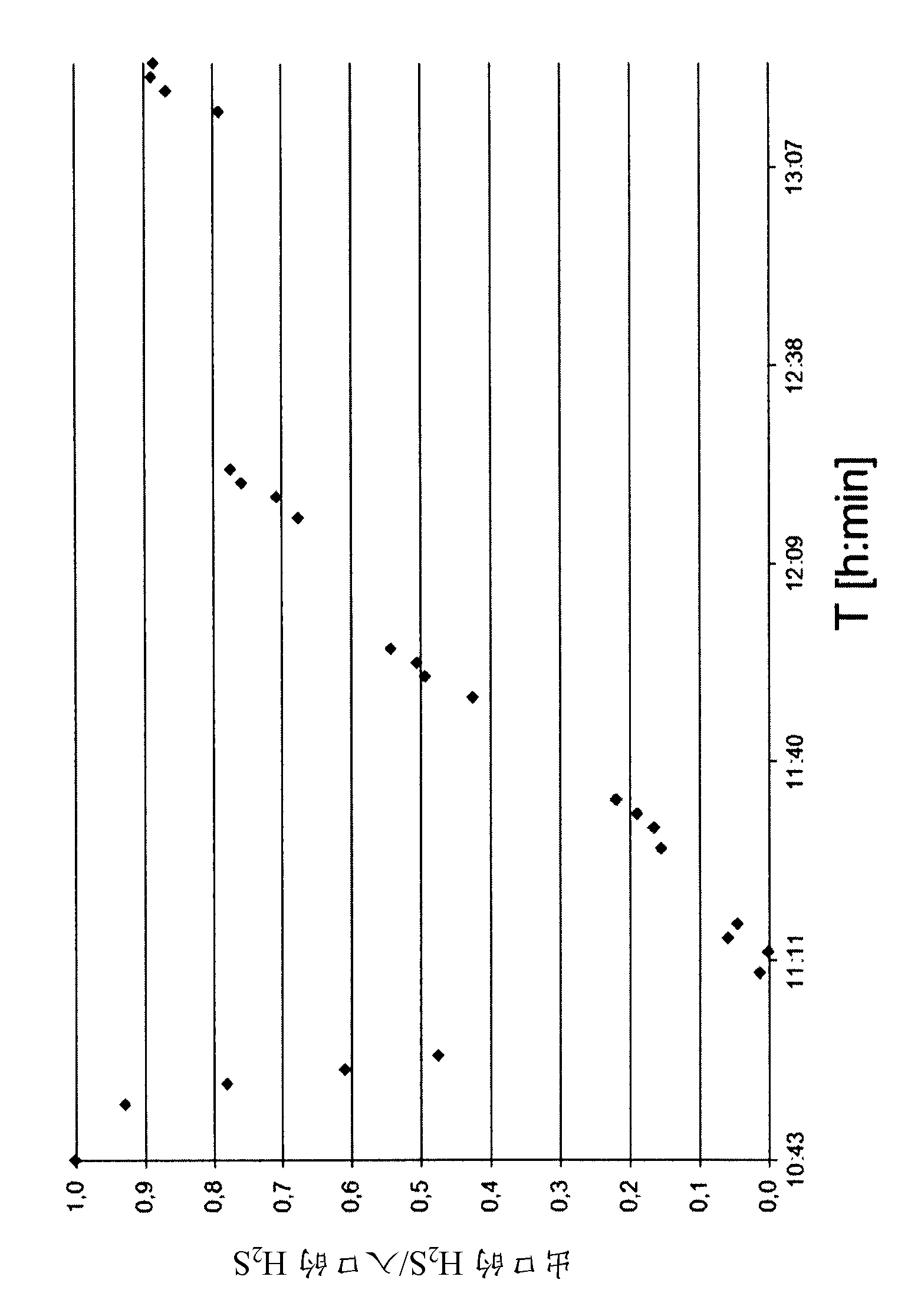

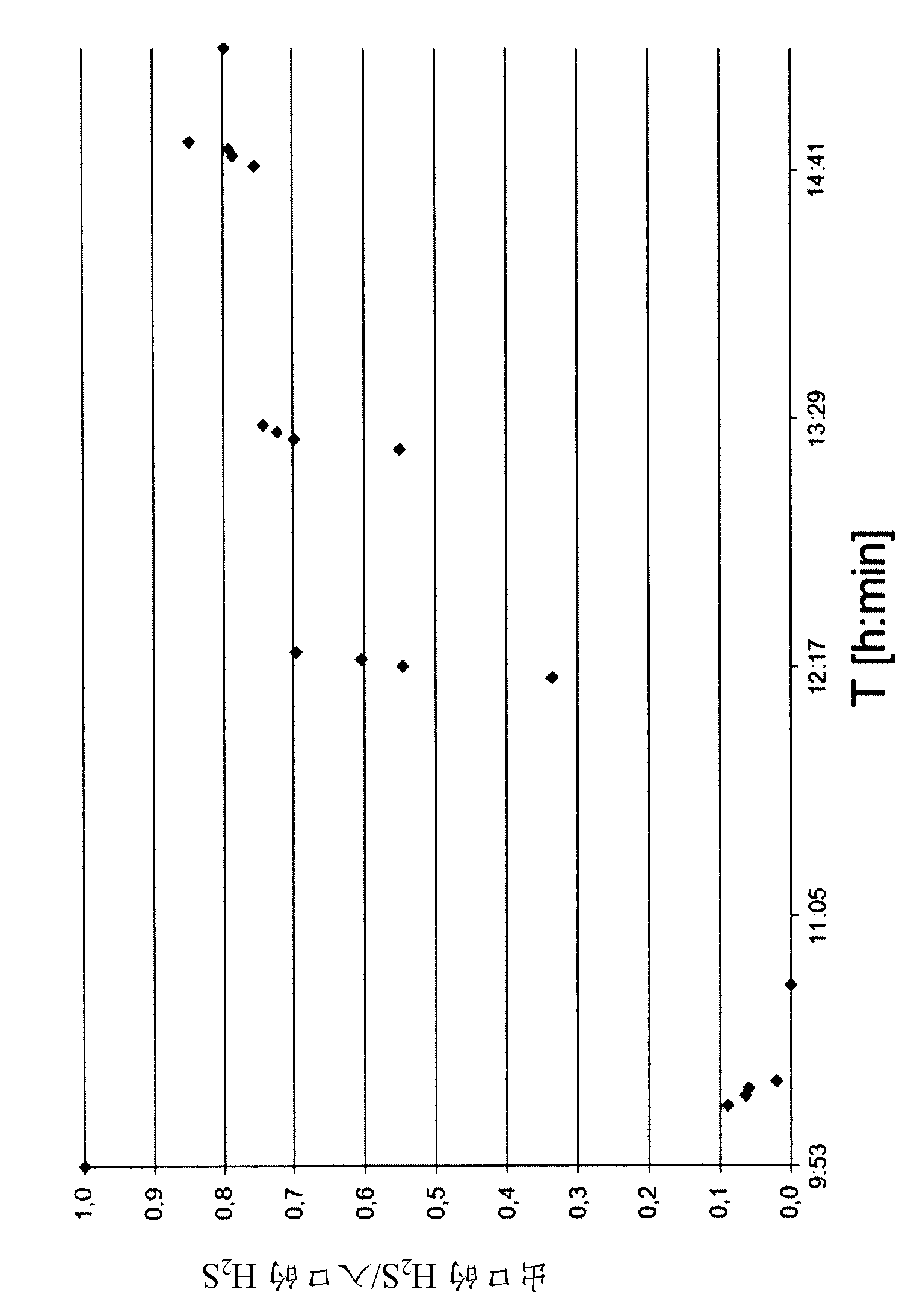

[0175] 3 Example 3: Two-stage cleaning scheme on pilot scale:

[0176] 3.1 Experimental equipment

[0177] Absorption experiments were performed in a pilot-scale facility in batch mode. The feed is provided by the synthesis gas preparation plant in Varkaus, Finland. The aqueous wash is performed using a packed bed absorption column, thereby forming the first stage.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The present description is related to the field of hydrocarbon production by gasification of carbonaceous material. It provides a two-stage gas washing method as a part of gas refining. More specifically it discloses a method for hydrogen sulfide and carbon dioxide removal from synthesis gas produced by gasification. It introduces a use of a novel combination of wash approaches for this application. As a specific application, this process is utilized as a part of biomass to liquid (BTL) process.

Description

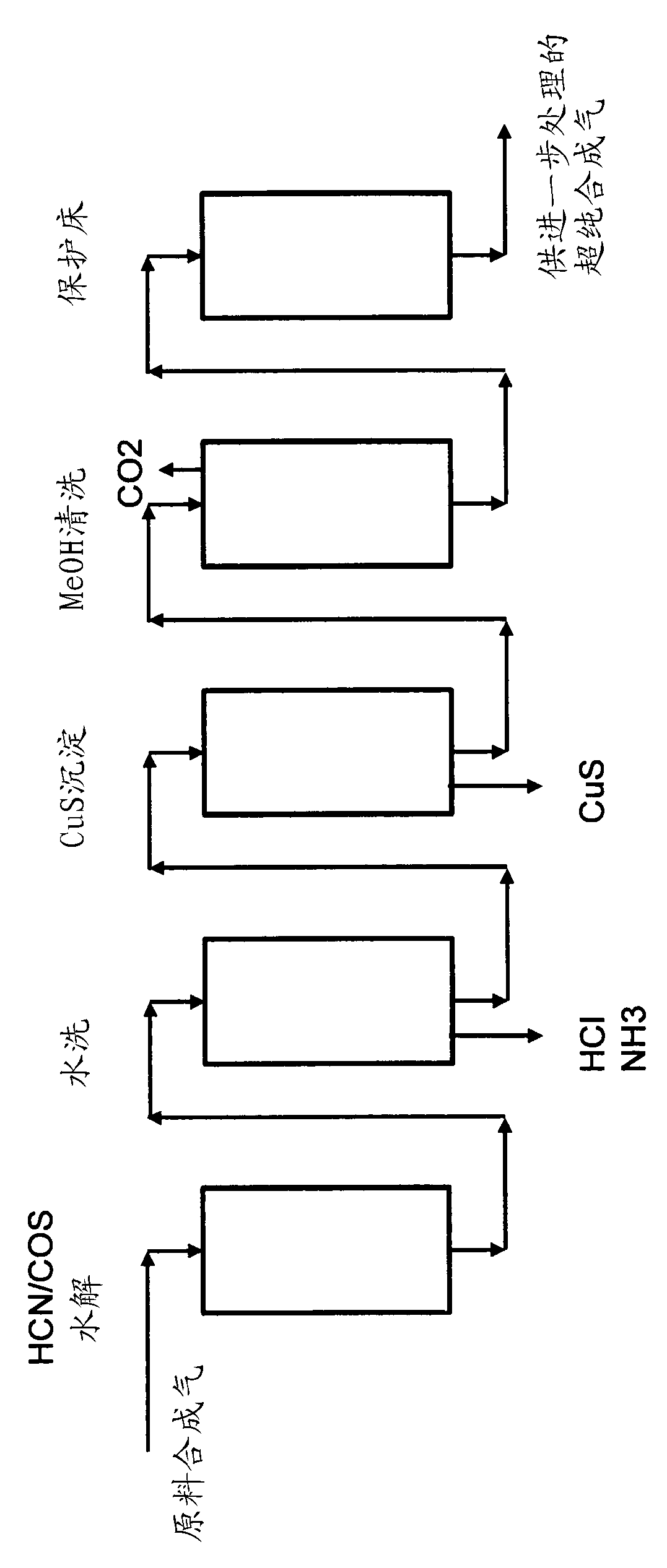

technical field [0001] This specification relates to the field of hydrocarbon production by gasification of carbonaceous materials. It provides a two-stage gas cleaning method as part of the syngas refining process. More specifically, it discloses a method for removing hydrogen sulfide and carbon dioxide from synthesis gas produced by gasification. It uses a novel combination of cleaning methods for this application, one of which involves chemical reactions and the other is based on physical absorption. As a specific application, the method is used as part of a biomass-to-liquids (BTL) process. Background technique [0002] Gasification of carbonaceous materials primarily produces a mixture of carbon monoxide and hydrogen called synthesis gas. Carbon dioxide, water and various hydrocarbons are by-products present in large quantities in the gasification product. Depending on the source and composition of the carbonaceous feedstock and the gasification conditions, the cont...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B01D53/52C10K1/08C10J3/00

CPCB01D53/1406B01D53/1462B01D53/526B01D2252/2021B01D2257/304B01D2257/504C01B17/20C01G3/06C10G2300/1011C10G2300/207C10G2300/44C10J3/00C10J2300/0916C10K1/004C10K1/005C10K1/085C10K1/108C10K1/165Y02E20/18Y02E50/30Y02P10/146Y02P20/145Y02P20/151Y02P30/20Y02C20/40

Inventor J.瓦尔斯特雷姆J.艾特塔马雅I.埃洛斯

Owner NESTE OIL OY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com