Safe food processor

A food processing machine, safe technology, applied in computer control, application, kitchen utensils, etc., can solve problems such as damage, human hands touch operating parts, etc., to achieve the effect of easy use, rich functions, and easy adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A safe food processing machine, comprising a base, a cup body arranged on the base, and a cup cover buckled on the cup body, the food processing machine also includes a main control circuit, a load, carrying the The circuit board of the main control circuit is arranged in the base, and the cup body and the base are provided with a coupler connecting the base and the electrical components in the cup, wherein, the cup body is provided with There is a switch, the opening and closing of the cup cover and the cup body controls the on-off of the switch, the switch is arranged between the load and the mains power supply, and the switch connects the load and the mains through a coupler. An electrical power supply, the cup body is provided with a wiring cavity for the switch to connect to the coupler.

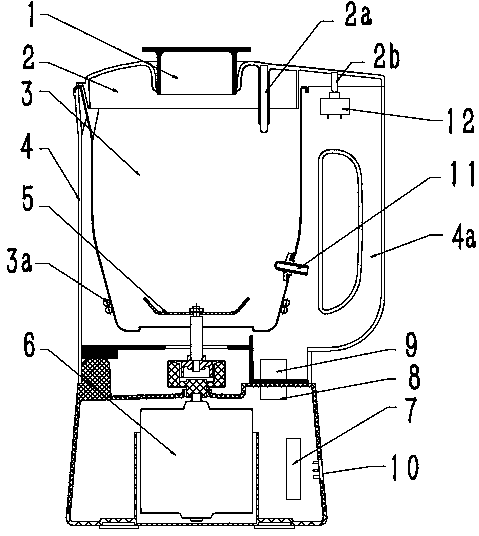

[0040] Such as figure 1As shown, in the embodiment, the load includes a heating device 3a disposed on the cup body and a motor 6 disposed in the machine base, and the motor 6 is...

Embodiment 2

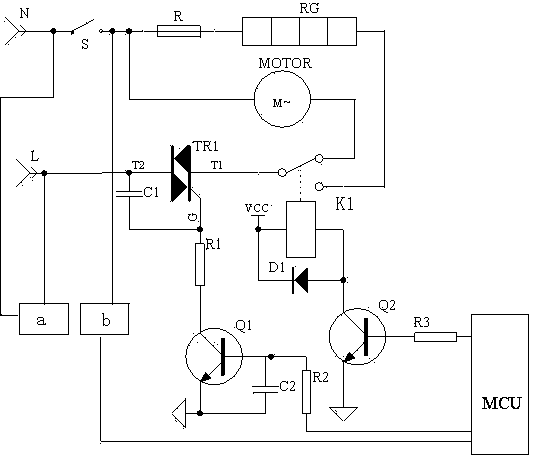

[0050] The difference between this embodiment and the above-mentioned embodiment 1 is that the main control circuit also includes a power supply circuit a for supplying power to the low-voltage module, and the power supply circuit a is connected to the mains power supply through a micro switch.

[0051] Such as Figure 4 As shown, the neutral line N of the mains power supply is electrically connected to one input end of the power supply circuit a through a micro switch S, and the live line L of the mains power supply is electrically connected to the other input end of the power supply circuit a.

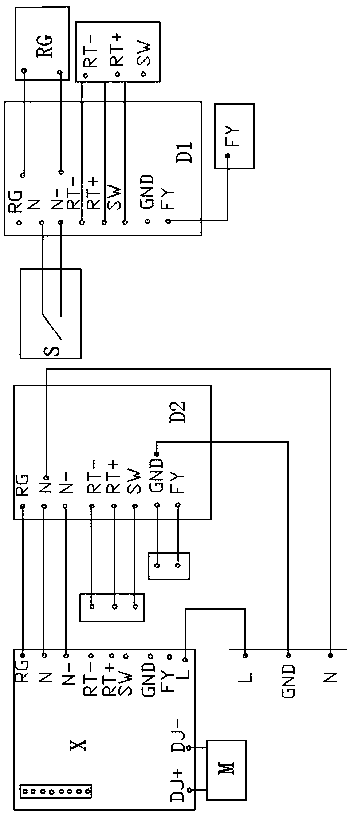

[0052] Such as Figure 5 As shown, the line connection of this embodiment is as follows: the mains power supply is a three-phase power supply including a live line L, a neutral line N and a bottom line GND. The live wire L is electrically connected to the live wire L end of the circuit board X through the power socket. The ground wire GND is respectively electrically connected to t...

Embodiment 3

[0057] The difference between this embodiment and the above-mentioned embodiment 1 is that the cup body is provided with a signal conversion unit for processing the signal detected by the signal detection device, and the signal conversion unit is electrically connected to the circuit board through the coupler .

[0058] Such as Figure 6 As shown, the outer cup 4 is provided with a handle 4a, the signal conversion unit 12 is disposed in the handle 4a, and the signal detection device includes a temperature signal detection device and a water level signal disposed on the side wall of the cup body. The detection device 11, and the overflow signal detection device 2a arranged on the cup cover 2.

[0059] Such as Figure 7 As shown, the line connection of this embodiment is as follows: the mains power supply is a three-phase power supply including a live line L, a neutral line N and a bottom line GND. The live wire L is electrically connected to the live wire L end of the circui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com