Jaw type crusher material discharge port stepless adjustment apparatus

A jaw crusher and stepless adjustment technology, which is applied in the field of mineral processing machinery, can solve the problems that the discharge port of the jaw crusher cannot be adjusted steplessly, and the automatic adjustment of the hydraulic system cannot be used, so as to achieve easy and fast operation and reduce labor. The effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

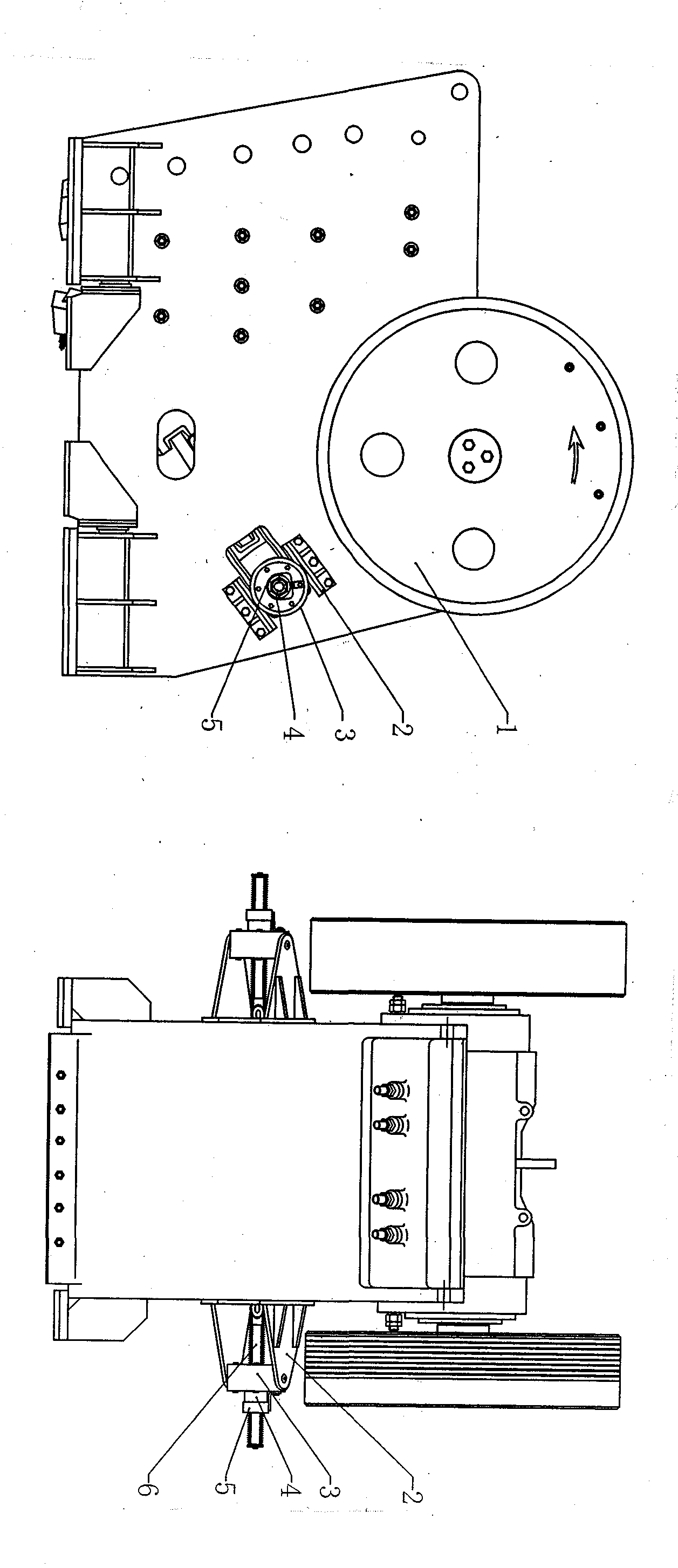

[0012] exist figure 1 Among them, the discharge port adjustment device is installed on both sides of the jaw crusher body (1) through the support (2). After the locking sleeve (5) is removed, turn the nut (4) installed in the nut seat (3), so as to drive the screw rod (6) to enter or withdraw from the body of the jaw crusher.

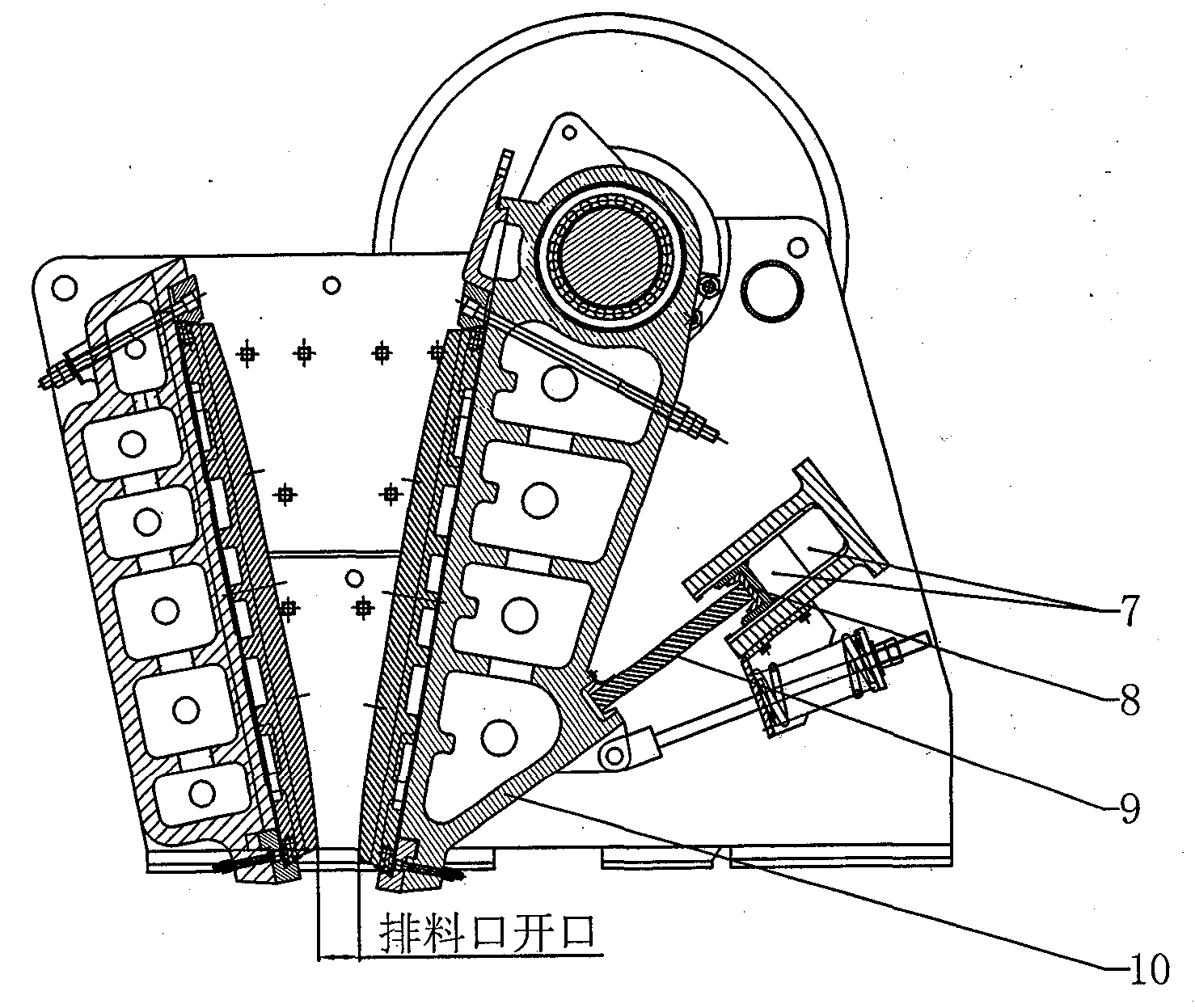

[0013] exist figure 2 Among them, two wedge-shaped blocks (7) are installed inside the jaw crusher, and one side of each wedge-shaped block is connected to the screw (6) through a pin shaft. When the screw (6) enters or exits the body of the jaw crusher At the same time, the wedge-shaped block is also driven into or out of the jaw crusher body, so that the superimposed thickness of the two wedge-shaped blocks will increase or decrease, thereby changing the movable jaw (10) through the toggle plate seat (8) and the toggle plate (9). ) to achieve the purpose of changing the size of the discharge opening.

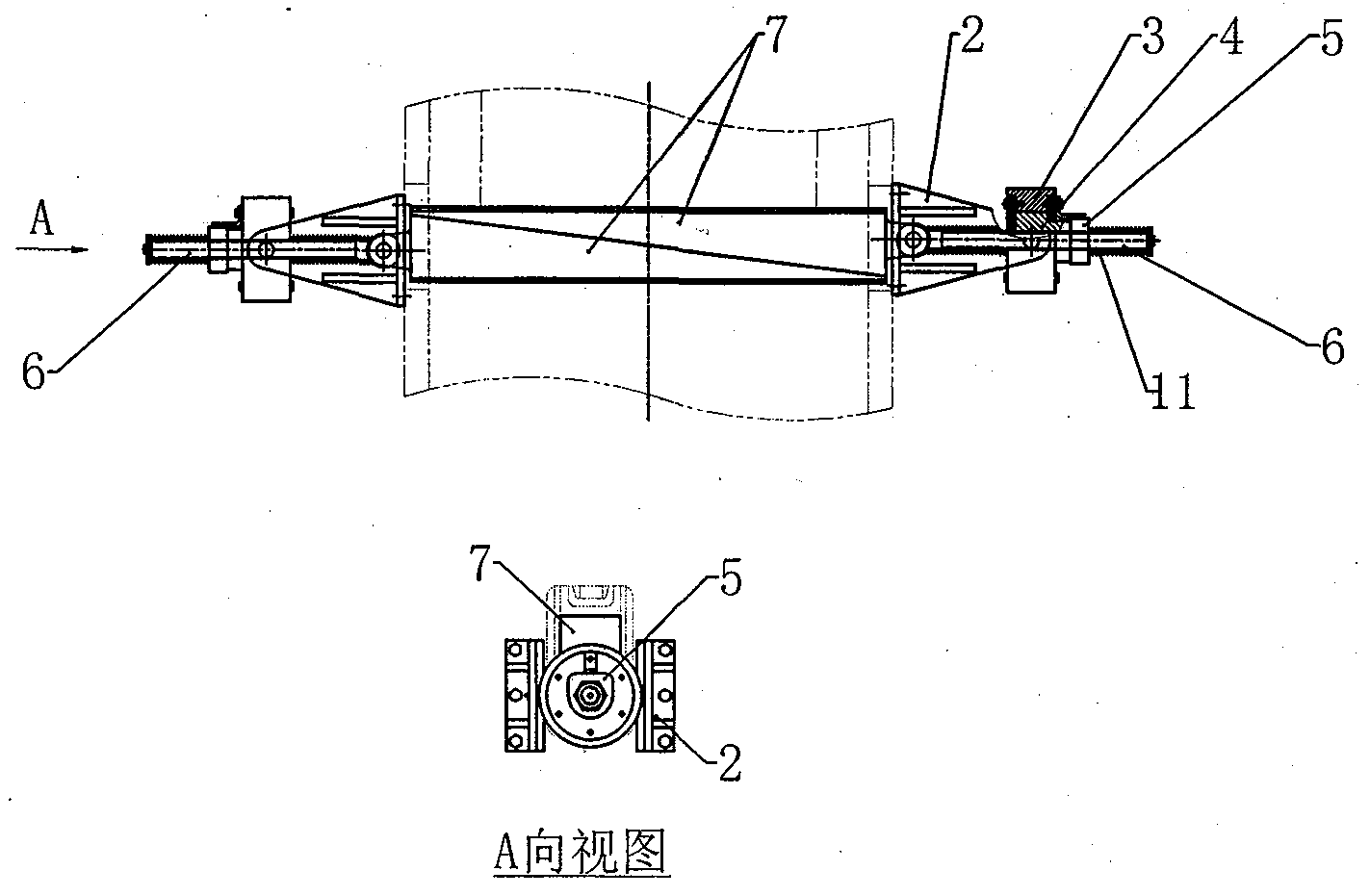

[0014] exist image 3 Among them, two wedge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com