Settling cyclonic micro-bubble flotation column separation unit and method

A micro-bubble flotation column and flotation column technology, which is applied in flotation, solid separation and other directions, can solve the problems of difficulty in pressure filtration and dehydration, waste of clean coal resources, and high consumption of chemicals, and achieve flexible and changeable product structure. , reduce pollution and ensure the effect of clean coal yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] An embodiment of the present invention will be further described below in conjunction with the accompanying drawings:

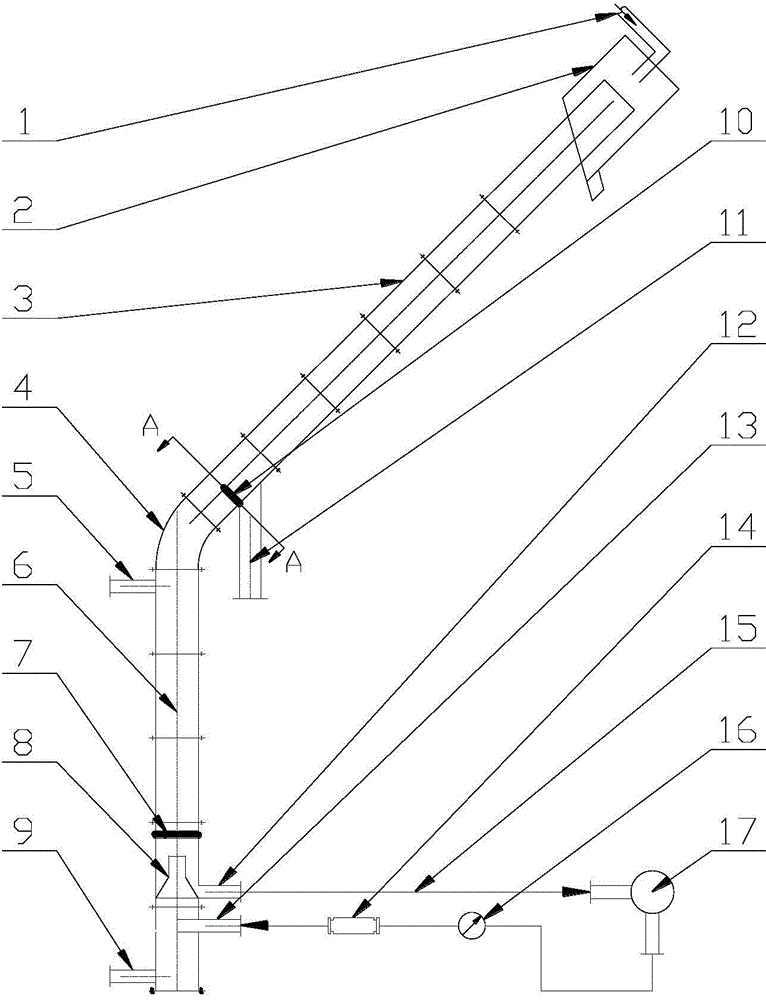

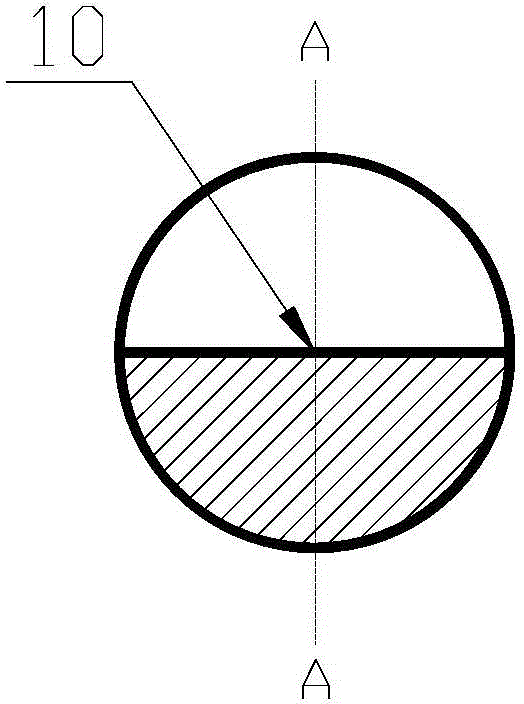

[0016] figure 1 As shown, the sedimentation cyclone microbubble flotation column sorting equipment of the present invention is mainly composed of spray water pipe 1, foam concentrate collection tank 2, inclined column 3, elbow 4, feed pipe 5, and vertical column 6. Stabilizing plate 7, cone 8; tailings pipe 9, interception plate 10, high ash fine mud discharge pipe 11, circulating slurry outlet pipe 12, circulating slurry inlet pipe 13, bubble generator 14, circulating slurry pipe 15. Pressure gauge 16, circulating slurry pump 17. The lower part of the vertical column 6 is provided with a steady flow plate 7, a cone 8, a circulating slurry outlet pipe 12, and a circulating slurry inlet pipe 13. The inclined column 3 is arranged on the top of the vertical column 6, and the vertical column The body 6 and the inclined column 3 are connected as a whole throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com