Three-product cyclone micro-bubble flotation column separation equipment and method

A micro-bubble flotation column and three-product technology, which is applied in flotation, cyclone device, solid separation, etc., can solve the problem that the filter press dehydration operation is difficult to carry out normally, which affects the economic benefit of the clean coal recovery rate of the enterprise, and the tailing coal runs rough. To achieve the effect of flexible product structure adjustment, reducing mechanical entrainment pollution, and ensuring the quality of clean coal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

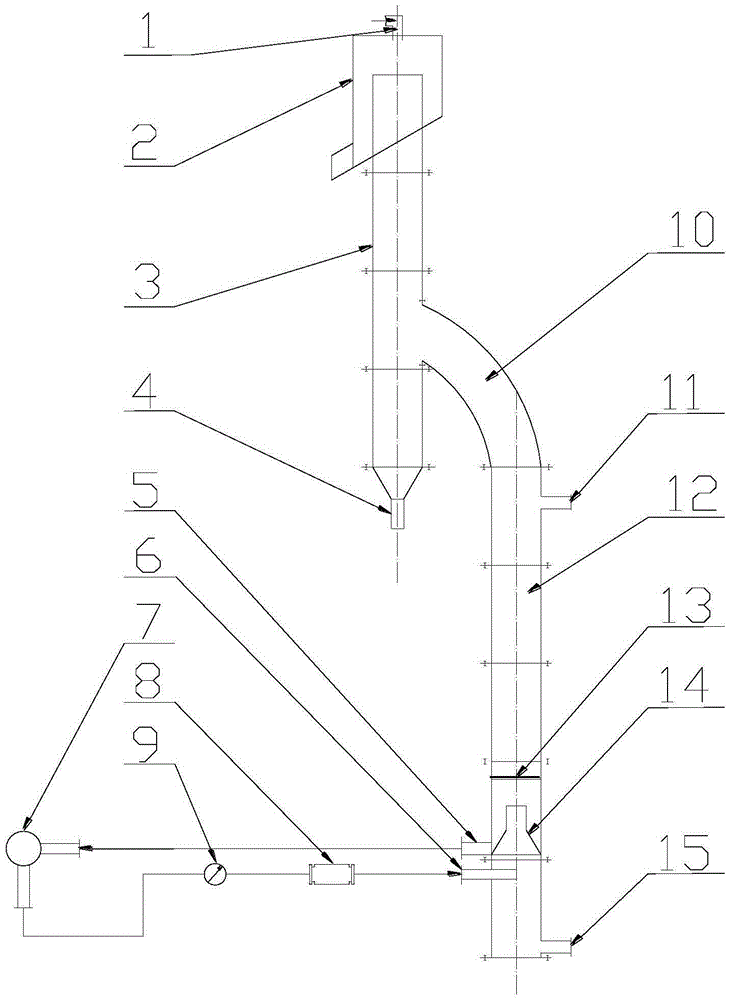

[0018] figure 1 As shown, the three-product cyclone micro-bubble flotation column separation equipment of the present invention is mainly composed of a spray water pipe 1, a foam concentrate collection tank 2, a flotation column, a medium ore discharge pipe 4, a circulating pulp extraction pipe 5, and a circulation Ore slurry feeding pipe 6, circulating ore slurry pump 7, bubble generator 8, pressure gauge 9, feed pipe 11, steady flow plate 13, conical cylinder 14, tailings pipe 15 constitute. The flotation column is composed of an upper flotation column 3 and a lower flotation column 12, the upper flotation column 3 and the lower flotation column 12 are connected in series through the elbow 10, and the lower part of the upper flotation column 3 is provided with a middle mine Discharge pipe 4, described feeding pipe 11 is arranged on the top of lower flota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com