Coarse aggregate separating device for cement concrete uniformity test

A technology of cement concrete and separation device, applied in solid separation, sieve, grid and other directions, can solve the problem of low recycling rate of concrete aggregate, and achieve high water resource utilization rate, fine and uniform spray particles, and spray particle size. equal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Specific embodiments of the present invention are provided below, and it should be noted that the present invention is not limited to the following specific embodiments, and all equivalent transformations done on the basis of the technical solutions of the present application all fall within the scope of protection of the present invention.

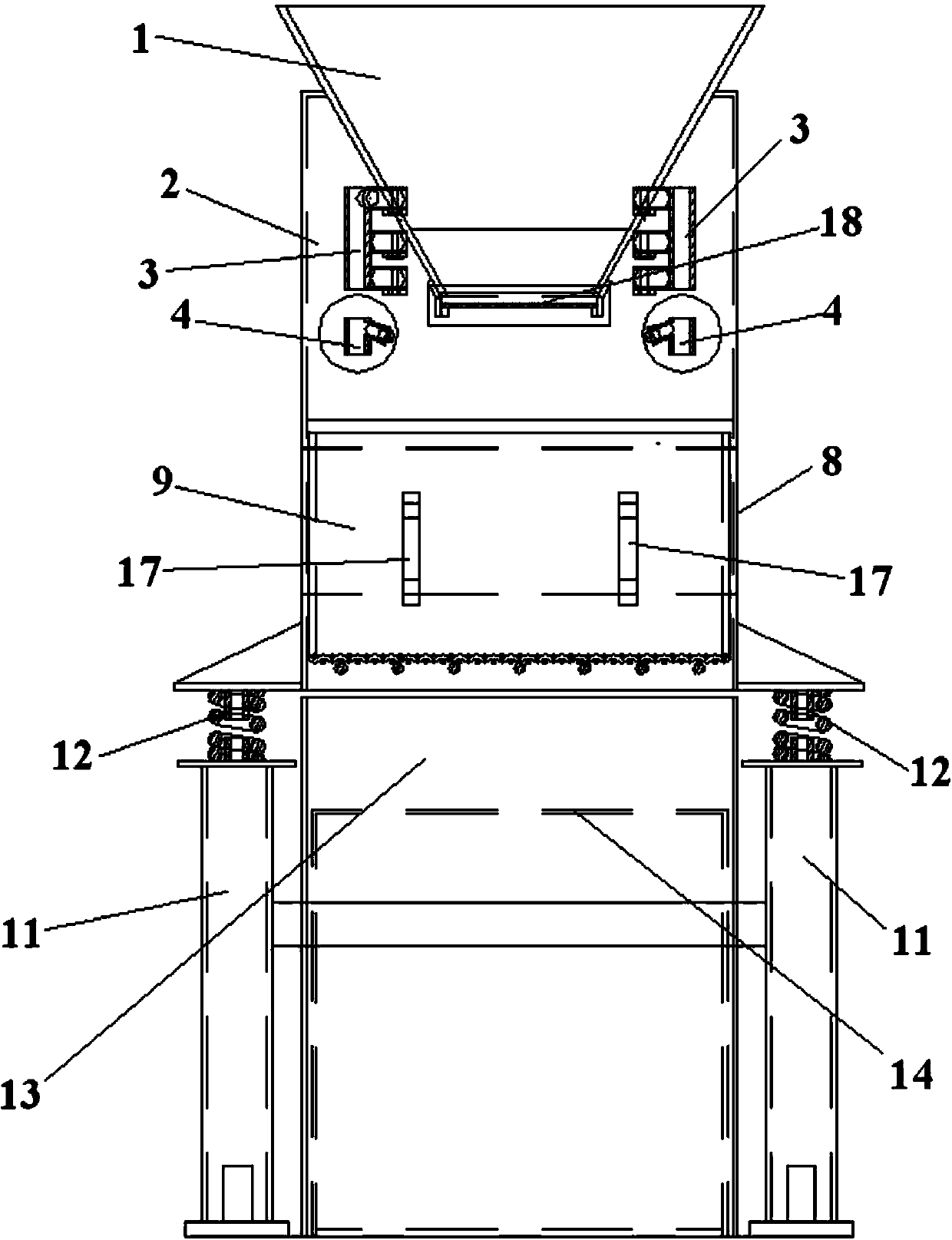

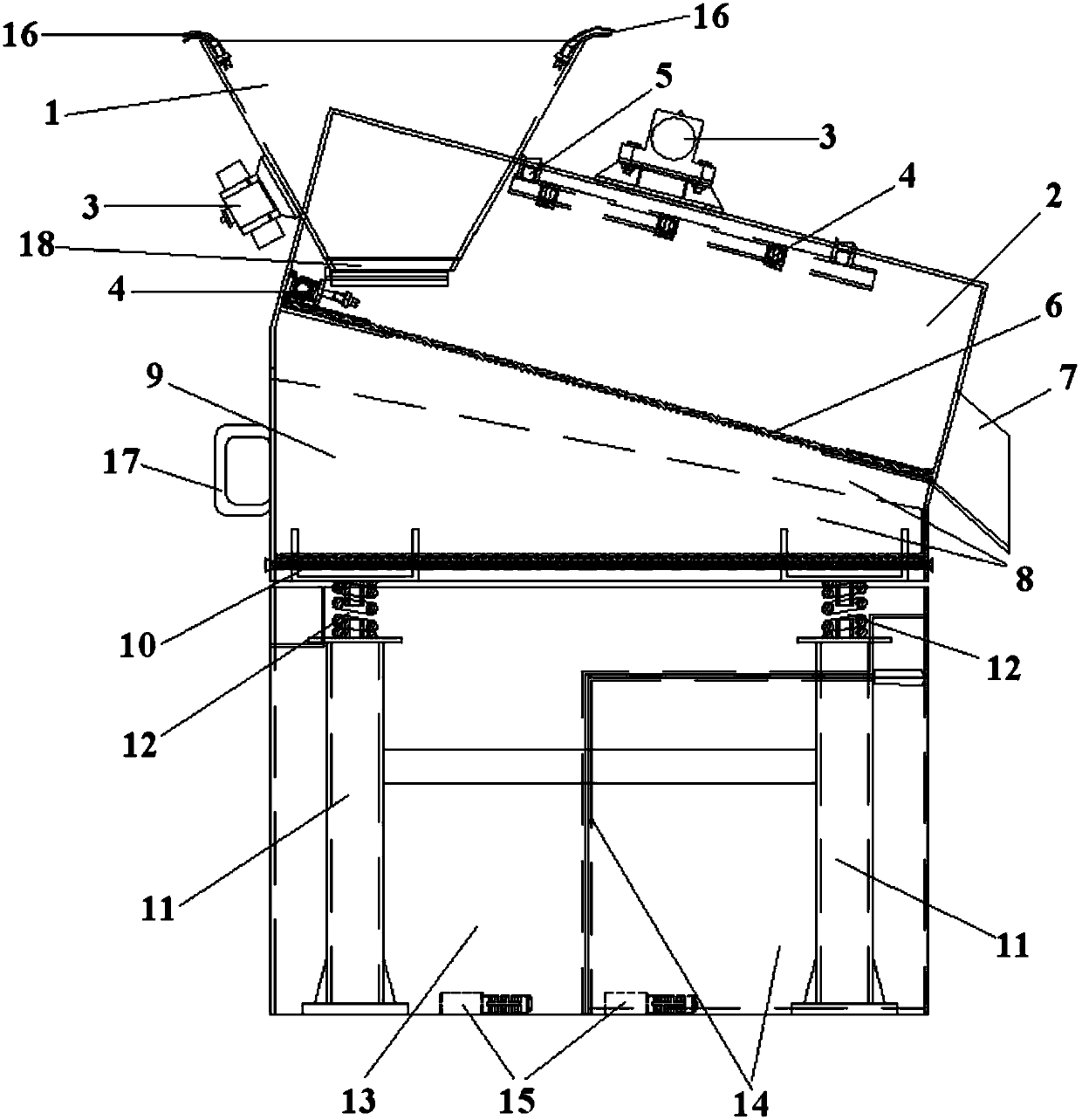

[0030] Comply with the above technical solutions, such as figure 1 and figure 2 As shown, this embodiment provides a coarse aggregate separation device for the homogeneity test of cement concrete, including a hopper 1, which is installed at one end of the screening box 2, and an excitation vibration device is installed on the side wall of the hopper 1. A device 3, a vibration exciter 3 is installed on the screening box 2, a pumping plate 18 is installed at the bottom of the hopper 1, the screening box 2 is installed obliquely, the end of the screening box 2 close to the hopper 1 is higher than the end far away from the hopper 1, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com