Adjustment Method of Crossbeam Synchronous Balance for NC Moving Beam Gantry Machine Tool

An adjustment method and crossbeam technology, which is applied to metal processing machinery parts, large fixed members, maintenance and safety accessories, etc., can solve problems affecting the positioning accuracy of machine tools, weight offset, damage to mechanical components, etc., and achieve a stable crossbeam synchronous balance adjustment , Eliminate the effect of over-tolerance inclination and no pressure impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

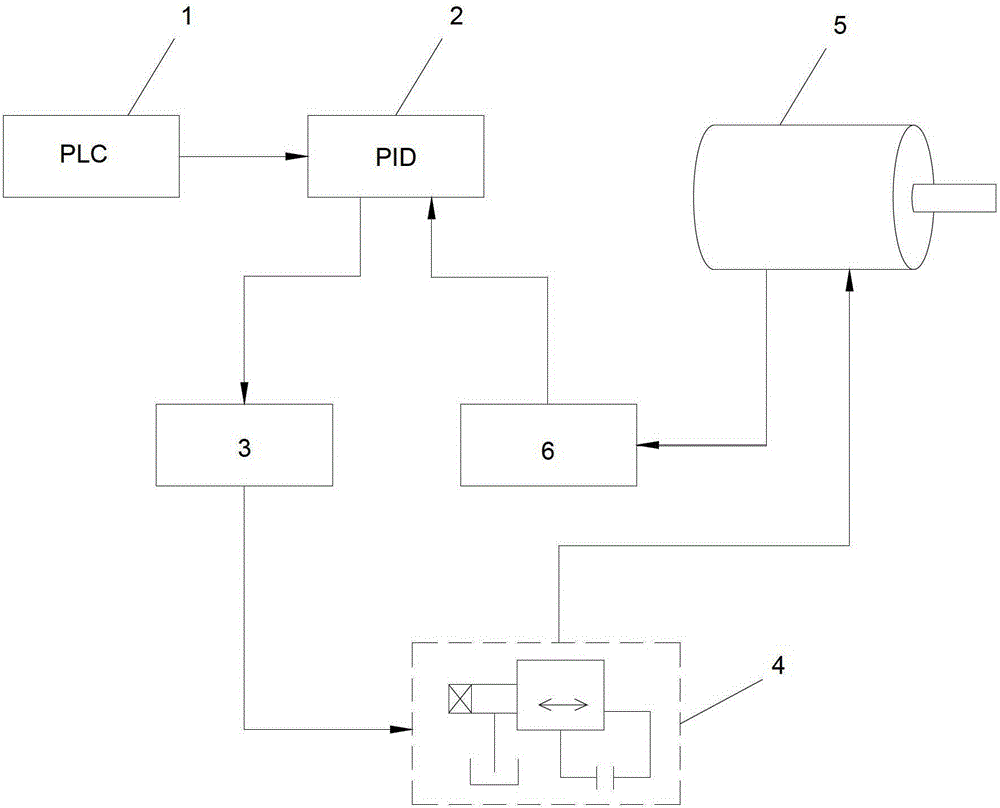

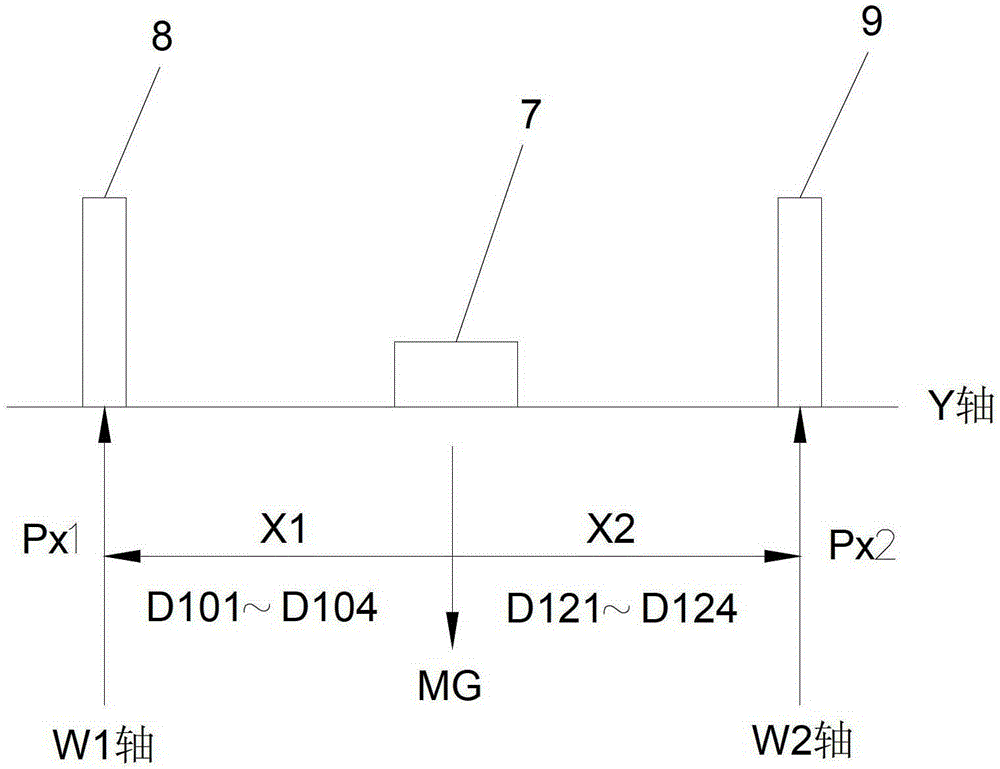

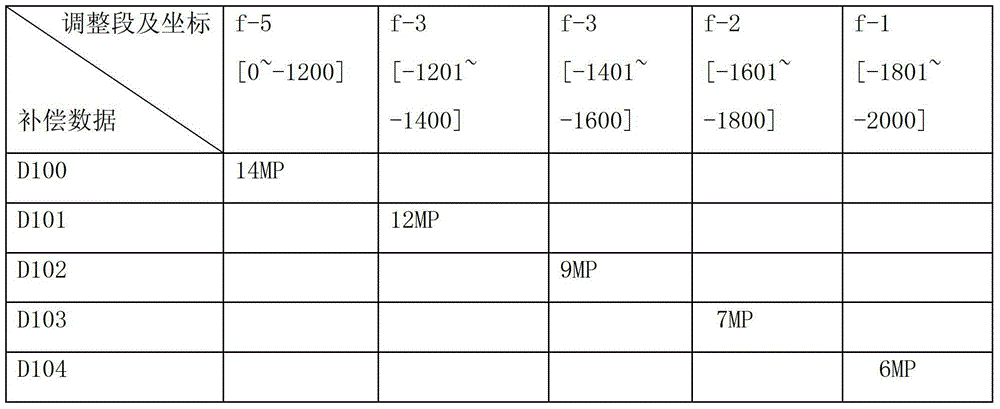

[0019] see figure 1 , the present invention provides a method for adjusting the synchronous balance of a crossbeam of a CNC moving beam gantry machine tool. The CNC moving beam gantry machine tool includes a left column, a right column and a beam that can move up and down. Head 7, the numerically controlled beam gantry machine tool also includes a PLC analog output module 1, a PID control board 2, a proportional valve amplifier 3, an electro-hydraulic proportional valve 4, an oil cylinder 5, and a pressure sensor 6 connected in sequence. The output end is connected to the PID control board 2 to form a closed-loop control. Wherein, the proportional valve amplifier 3 includes a left proportional valve amplifier and a right proportional valve amplifier respectively connected to the PID control board 2 . The electro-hydraulic proportional valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com