High-adaptability temperature control device of loop heat pipes

A loop heat pipe and temperature control device technology, which is applied in the direction of the device for controlling the living conditions of the spacecraft, can solve the problem of wasting the electric energy of the spacecraft, and achieve the effect of saving electric energy and satisfying the heat dissipation demand.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

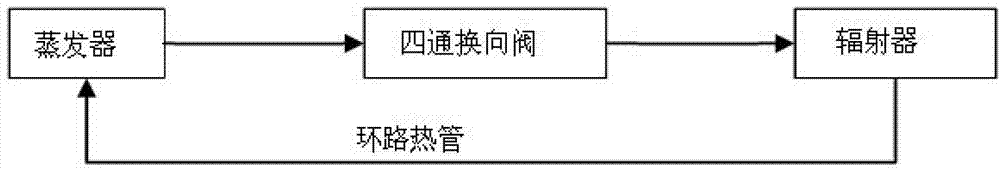

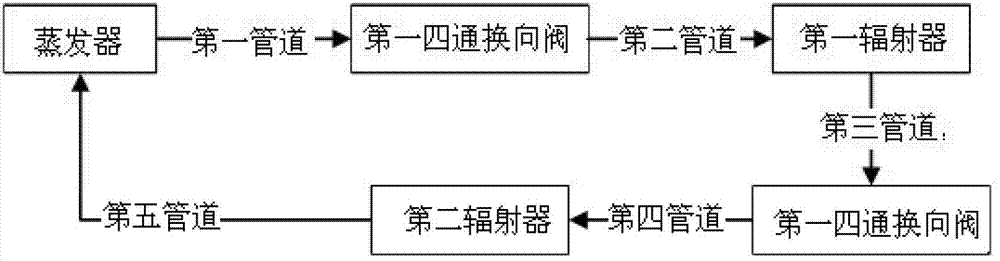

[0034] This embodiment provides a highly adaptable loop heat pipe temperature control device with the function of once changing the area of the radiator, including an evaporator, a plurality of four-way reversing valves and a plurality of radiators, the evaporator, a plurality of four-way The reversing valve and the plurality of radiators are connected to each other through loop heat pipes to form a loop.

[0035] Further, there are two radiators, including a first radiator and a second radiator, one four-way reversing valve, and the loop heat pipe sequentially passes through the evaporator, the four-way reversing valve, the first The radiator, the four-way reversing valve, and the second radiator return to the evaporator to form a heat dissipation loop with the function of one-time transformation of the radiator area.

[0036] Further, the heat dissipation loop with the function of primary transformation of the radiator area is specifically:

[0037] -In the initial stage ...

Embodiment 2

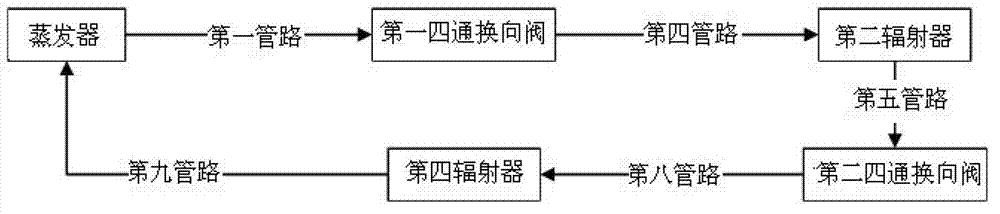

[0042] This embodiment provides a highly adaptable loop heat pipe temperature control device with the function of secondary conversion of the radiator area, including an evaporator, a plurality of four-way reversing valves and a plurality of radiators, the evaporator, a plurality of four-way The reversing valve and multiple radiators are connected to each other through loop heat pipes to form a loop.

[0043] Further, there are four radiators, including the first radiator, the second radiator, the third radiator and the fourth radiator, and there are two four-way reversing valves, including the first four-way reversing valve. The valve, the second four-way reversing valve, the four radiators and the two four-way reversing valves are connected to each other through loop heat pipes to form a heat dissipation loop with the function of secondary transformation of the radiator area.

[0044] Further, the heat dissipation loop with the function of secondary transformation of the radia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com