Pneumatic conveying device

A technology of transportation device and transportation pipe, which is applied in the direction of transportation and packaging, packaging, and the type of packaged items. It can solve the problems of powdery material explosion, wear and tear of conveying pipes, and material accumulation, etc., and achieve low conveying speed, prevent blockage, and reduce static electricity. charge effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

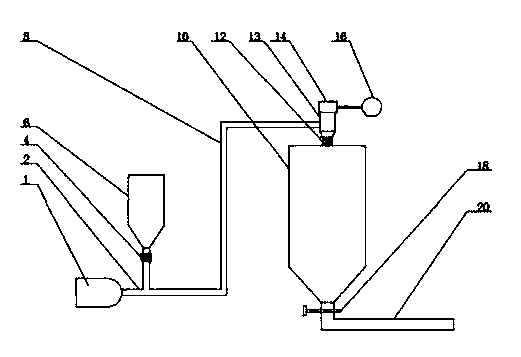

[0012] The present invention will be further described below in conjunction with the accompanying drawings.

[0013] Such as figure 1 As shown, the present invention comprises a hollow silo 6, a storage hopper 13 and a silo 10, and the silo 6 and the storage silo 10 communicate with each other through a transport pipe 8 provided with a first rotary valve 4, and the storage hopper 13 is connected to the hopper 10. The bins 10 are communicated through the second rotary valve 12, and there is a feeding pipe 20 connected to the packaging bag under the bin 10, and a gas pipe 2 connected to the atmosphere is connected to the transportation pipe 8, and the gas pipe 2 is located behind the first rotary valve 4 . An air filter 1 is also connected to the air pipe 2 . A dust collector 14 is connected between the vacuum generator 16 and the storage material. The feeding pipe 20 is also connected with a butterfly valve 18 .

[0014] Principle of the present invention is as follows:

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com