Tank opening overflowing gas collecting and processing device

A processing device and gas technology, applied in the field of gas collection devices, can solve problems affecting safe production, environmental pollution, environmental pollution, etc., and achieve the effect of realizing controllable processing, meeting safety production needs, and safety and environmental protection technical requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

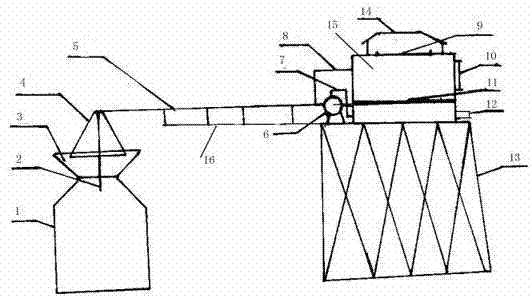

[0010] The main structure of the present invention includes: oil storage tank 1, inner liquid pipe 2, liquid collection tank 3, gas collection cover 4, double-layer pipe 5, vacuum pump 6, liquid inlet pipe 7, overflow pipe 8, oil separation film 9, remote transmission Type liquid level gauge 10, gas distribution network 11, sewage outlet 12, bracket 13, protective cover 14, reaction chamber 15, power distribution system.

[0011] The liquid collecting tank 3 is funnel-shaped, and is flange-welded with the mouth of the oil storage tank 1. Preferably, the diameter of the opening of the liquid collecting tank 3 is 35-40 cm larger than the diameter of the opening of the oil storage tank 1. The gas collection hood 4 is arranged above the notch of the liquid collection tank 3 and is in the shape of an inverted funnel for collecting the spilled gas. There is an opening at the top, and the opening is connected to the vacuum pump 6 through the outer air pipe 5, and the vacuum pump 6 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com