Sound-absorbing damping coating

A technology of damping coatings and coatings, applied in the field of sound-absorbing damping coatings and indoor installation of sound-absorbing walls, to achieve good sound-absorbing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

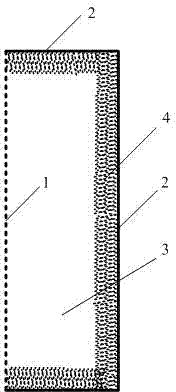

[0016] The specific embodiment of the present invention is as figure 1 shown.

[0017] A common microporous metal sound-absorbing wall is generally composed of a porous metal panel 1 , a non-porous metal plate 2 and an internal air cavity 3 surrounded by it. The microporous metal sound-absorbing wall has a good sound-absorbing effect on high-frequency noise, and has a certain sound-absorbing effect on intermediate-frequency noise, but there is a problem that the sound-absorbing effect on low-frequency noise is not good.

[0018] The embodiment of the present invention is: pour 30-35% of acrylic emulsion, 8-12% of water-based styrene-acrylic emulsion, and 2-5% of silicone into the stirring tank, add an appropriate amount of pure water, and fully stir until the components are in a uniform state , add aluminum fiber 5-15%, plasticizer 2-5%, and then fully stir evenly.

[0019] During the processing and assembly process of the microporous metal sound-absorbing wall, the coating...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com