Down filling head

A technology of pile head and down, which is applied in the field of down head, which can solve the problems such as airflow cannot be discharged, waste down, environmental problems, etc., and achieve the effect of ensuring air return

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

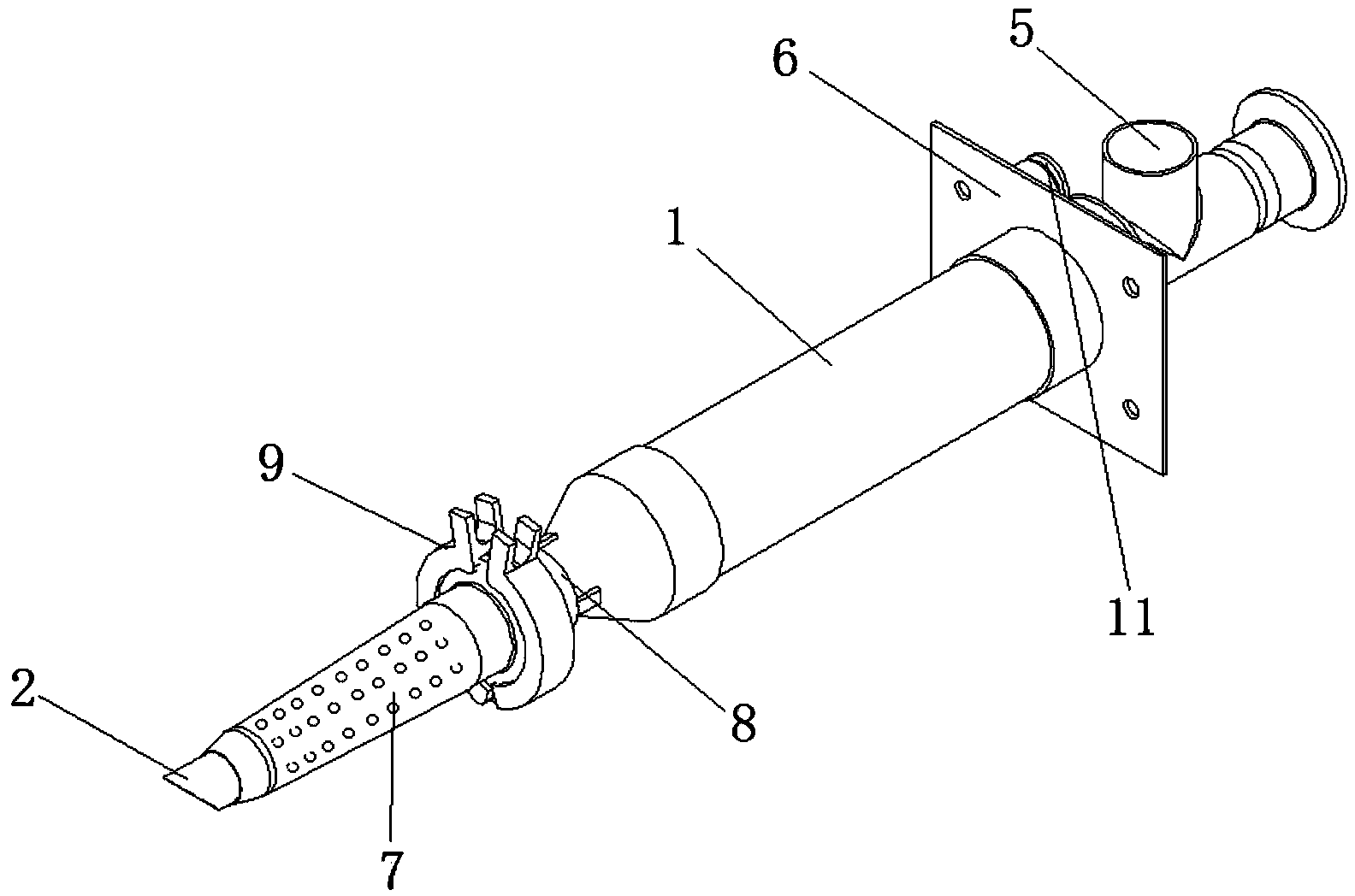

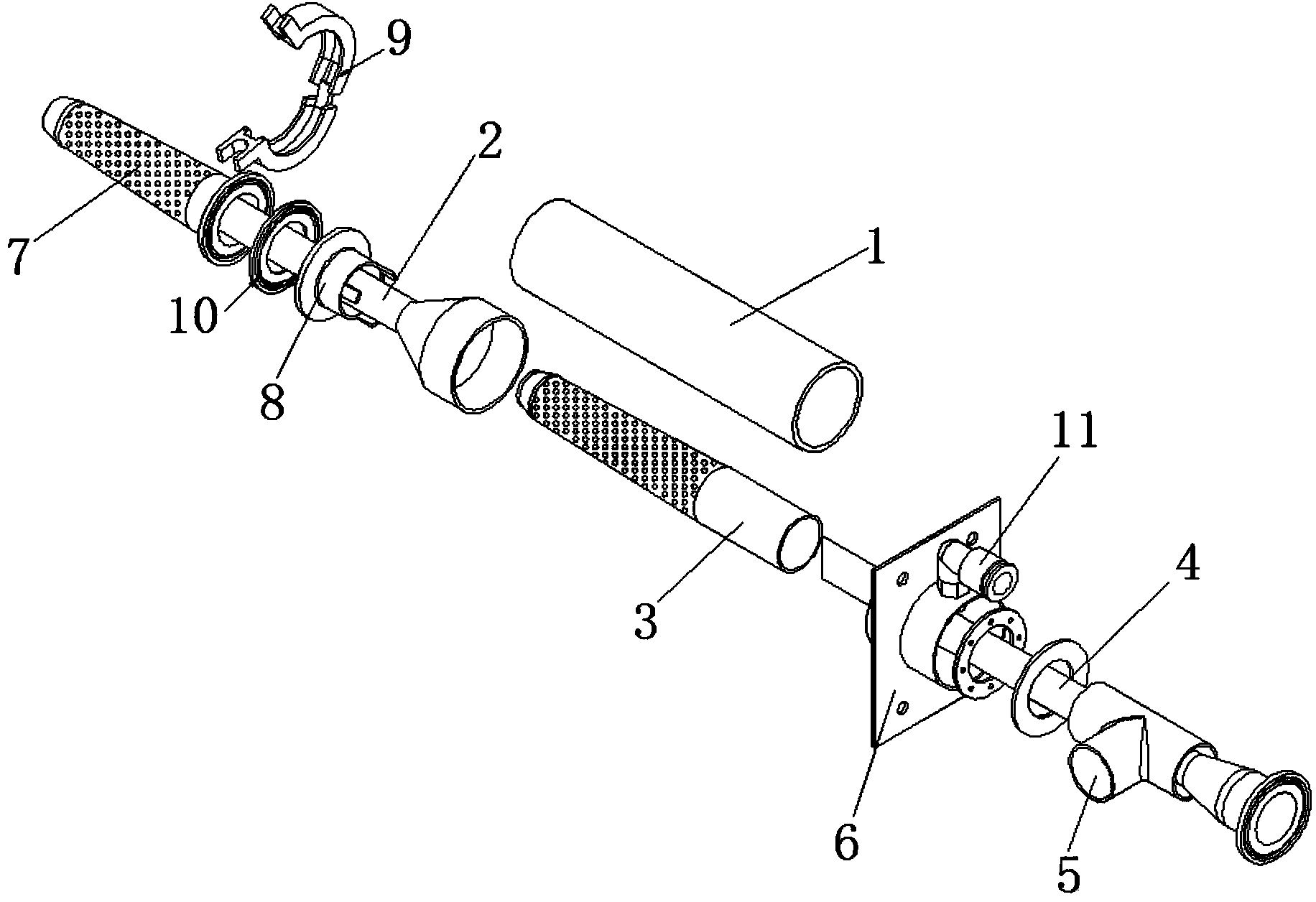

[0021] Such as figure 1 , 2 As shown, a down filling head includes a down output pipe 4, an air return pipe 3 and an outer casing, the outer casing includes a lumen 1 and a down filling nozzle 2 connected to one end of the lumen 1, and the other end of the lumen 1 adopts the method The blue 6 is closed, and the lumen 1 is made of transparent glass material, so that the inside thereof can be observed conveniently.

[0022] The air return pipe 3 is sleeved outside the down output pipe 4, an air return space is formed between the air return pipe 3 and the down output pipe 4, and the gap between one end of the air return pipe 3 and one end of the down output pipe 4 is smaller than the gap that the down can pass through (The connection at this end can also be a sealed connection), and the other end of the air return pipe 3 is sealed with the other end of the down output pipe 4.

[0023] One end of the down output pipe 4 and the air return pipe 3 is arranged in the lumen 1, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com