Quick constructing method of cross-line bridge

A technology for crossing lines and bridges, which is applied in the field of rapid construction methods of cross-line bridges, can solve problems such as poor traffic, and achieve the effect of rapid bridge completion and significant social benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

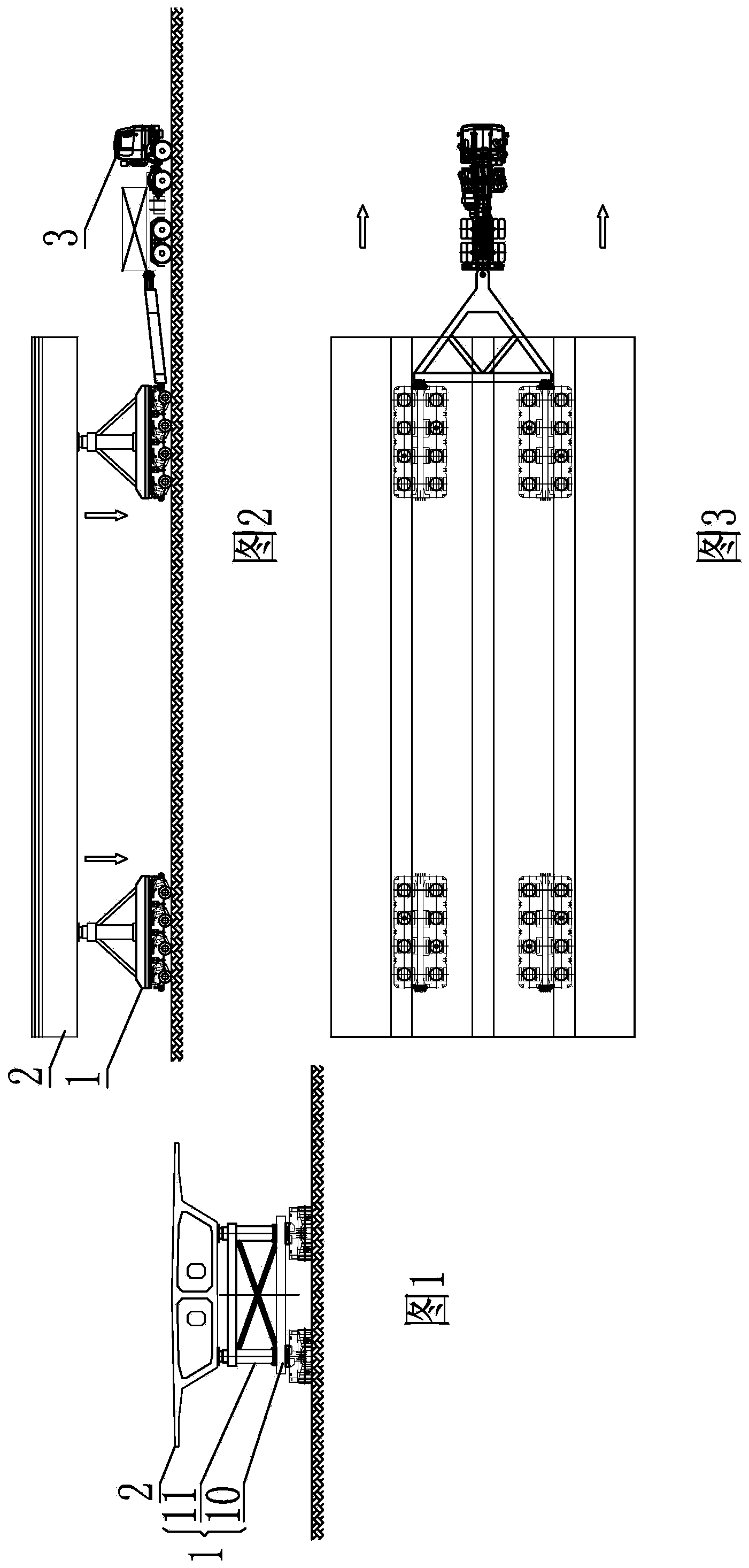

[0030] A rapid construction method for a cross-line bridge. An elevated road is erected along the construction road and disconnected at a vertical crossing position with an existing road 5 . First of all, a brief introduction to the equipment used for it - the integrated vehicle for transport and frame 1:

[0031] The frame-transporting integrated vehicle 1 includes a power platform vehicle 10 and a carrying bracket 11 arranged on the power platform. The power flatbed 10 is based on four-axis and six-axis modules, which can be spliced vertically and horizontally to meet the transportation of goods of different dimensions and weights; the bottom of the power flatbed 10 is connected to a hydraulic suspension system that can rotate. The piggyback bracket 11 is used to carry the cross-line bridge segment 2. After the transportation is in place, the piggyback bracket 11 cooperates with the power flatbed truck 10 to carry out three-dimensional adjustment and positioning of the cro...

Embodiment 2

[0039] Such as Figure 10-18 Shown: The construction method specifically includes the following steps:

[0040] The prefabricated cross-line bridge segment 2 is carried by the integrated vehicle 1 to the beam yard: the integrated vehicle 1 is lowered by its own lifting system and then powered by the trailer 3 at a low position, and carried along the existing road 5 To the outside between the viaduct bridge piers at the road installation site;

[0041] The frame-transporting integrated vehicle 1 is separated from the additional trailer 3, which uses its own micro-power to rotate the vehicle 90 degrees on the spot and then uses its own suspension system to rotate 90 degrees;

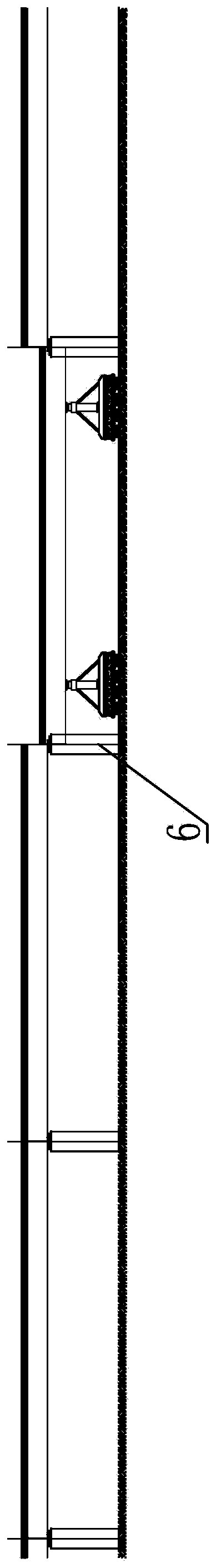

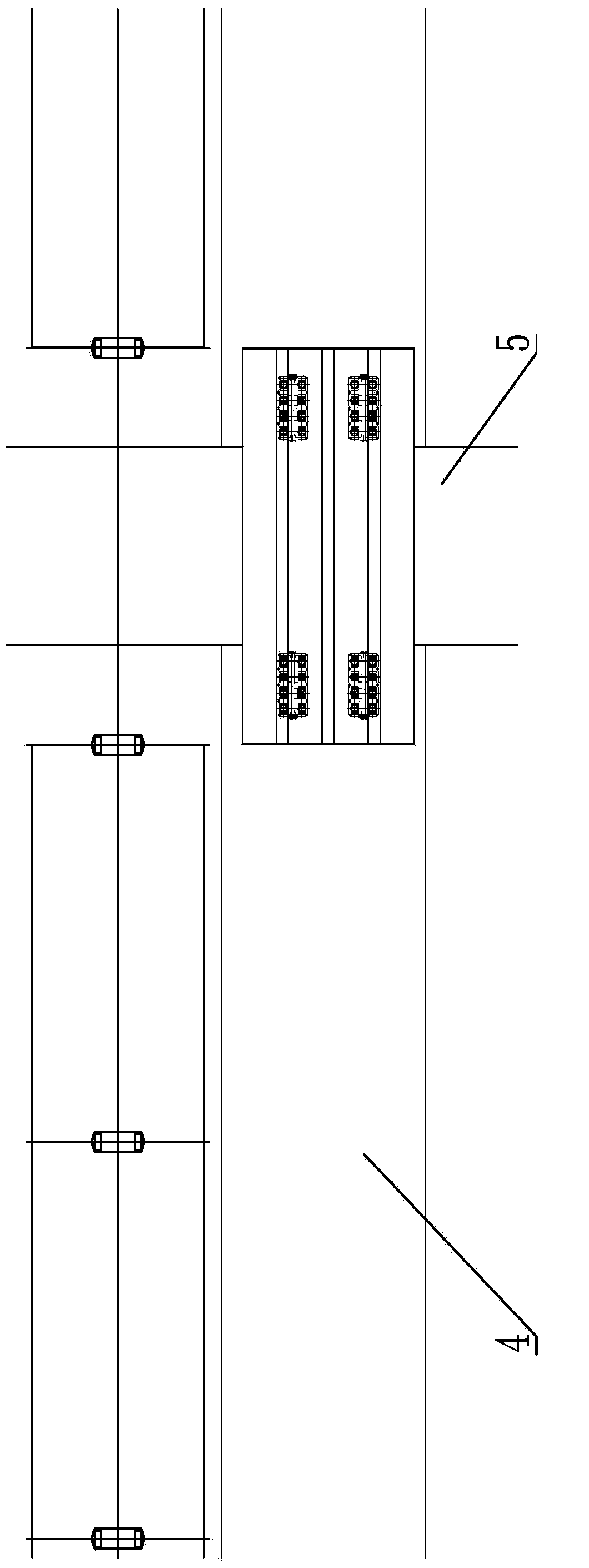

[0042] The integrated frame transport vehicle 1 is lifted by its own lifting system, so that the bottom of the span bridge segment 2 is higher than the span bridge pier support 6, and the frame transport integrated vehicle 1 enters between the viaduct bridge piers through its own micro power; The integra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com