Cross-shaped cast-in-place pile and method for constructing same

A construction method, cast-in-situ pile technology, applied in sheet pile walls, foundation structure engineering, construction, etc., to achieve the effects of saving concrete, increasing vertical bearing capacity, and small pressure-in resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

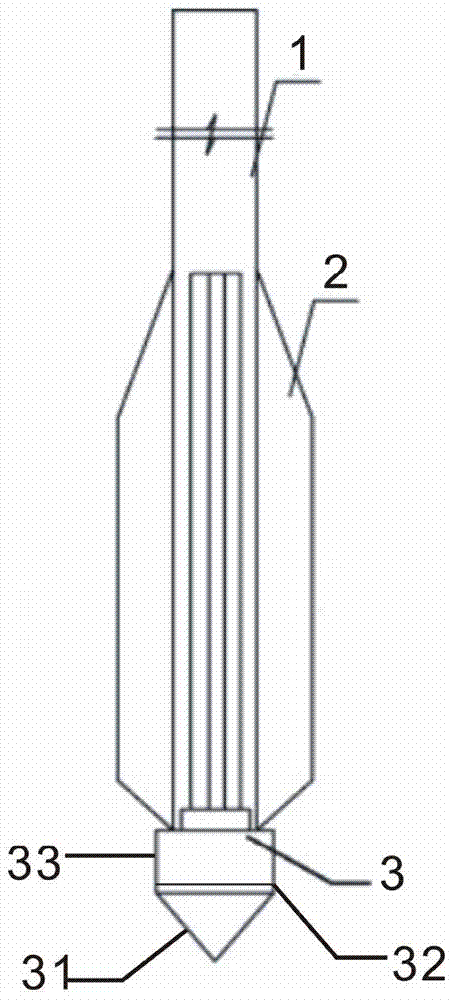

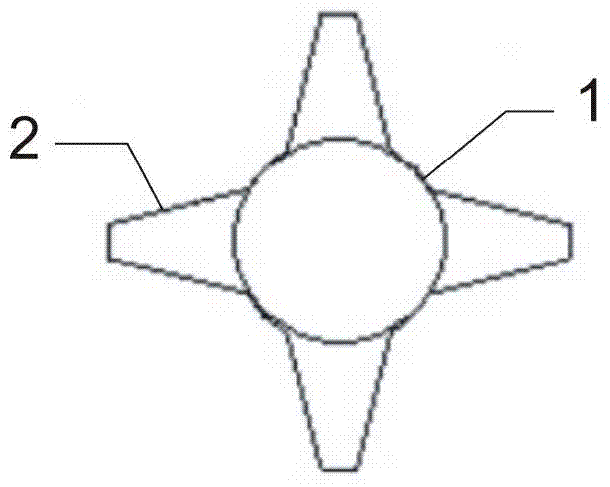

[0024] Embodiment 1: cross cast-in-situ pile, including steel pipe 1, steel flange 2, pile shoe 3, the cross section of described steel pipe 1 is circular, the middle and lower part of steel pipe 1 is welded closed steel flange 2, the steel flange 2 The cross section is cross-shaped, and the lower end of the steel flange 2 is connected to the spud can 3; the spud can 3 includes a tapered oblique cross plate 31, the bottom of the oblique cross plate 31 is fixedly connected with the end plate 33, and the diameter of the end plate 33 and The bottom diameters of the inclined cross plates 31 are the same; the length of the steel flange 2 is 0.7m.

Embodiment 2

[0025] Embodiment 2: cross cast-in-place pile, including steel pipe 1, steel flange 2, pile shoe 3, the cross section of described steel pipe 1 is circular, the middle and lower part of steel pipe 1 is welded closed steel flange 2, the steel flange 2 The cross section is cross-shaped, and the lower end of the steel flange 2 is connected to the spud can 3; the spud can 3 includes a tapered oblique cross plate 31, the bottom of the oblique cross plate 31 is fixedly connected with the end plate 33, and the diameter of the end plate 33 and The bottom diameters of the inclined cross plates 31 are the same; the length of the steel flange 2 is 0.8m.

Embodiment 3

[0026] Embodiment 3: cross cast-in-place pile, including steel pipe 1, steel flange 2, pile shoe 3, the cross section of described steel pipe 1 is circular, the middle and lower part of steel pipe 1 is welded closed steel flange 2, the steel flange 2 The cross section is cross-shaped, and the lower end of the steel flange 2 is connected to the spud can 3; the spud can 3 includes a tapered oblique cross plate 31, the bottom of the oblique cross plate 31 is fixedly connected with the end plate 33, and the diameter of the end plate 33 and The bottom diameters of the inclined cross plates 31 are the same; the length of the steel flange 2 is 0.9m.

[0027] The construction method of the above-mentioned cross cast-in-place pile has the following steps: S1. Pre-embed the concrete pile shoe; S2. After the pile driver is in place, insert the steel pipe welded with the steel convex edge into the concrete pile shoe; S3. Vibration pressure or static pressure Sink the steel pipe into the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com