Method for preventing residual coal during top coal caving on fully mechanized caving face

A fully mechanized caving face and residual coal technology, applied in surface mining, earthwork drilling, underground mining, etc., can solve problems such as loss of top coal, failure to recover, aggravation of spontaneous combustion of residual coal in goafs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

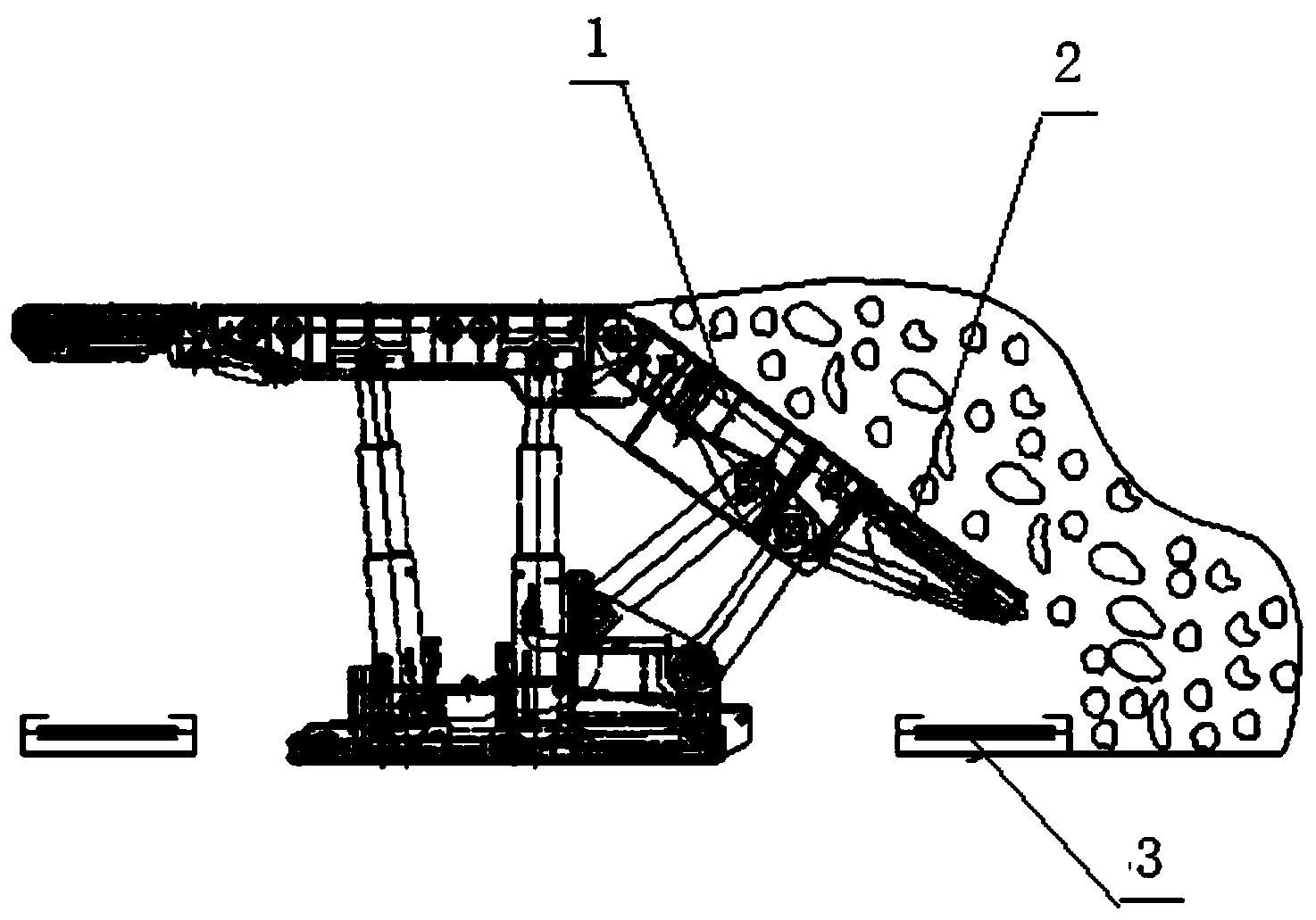

[0011] figure 1 It is a picture of the situation before pulling the rear conveyor after top coal caving. It can be seen from the figure that the top coal flows into the rear conveyor along the slope of the tail beam.

[0012] The following is based on Figure 2-4 Explain the method of preventing residual coal when caving top coal in fully mechanized caving face.

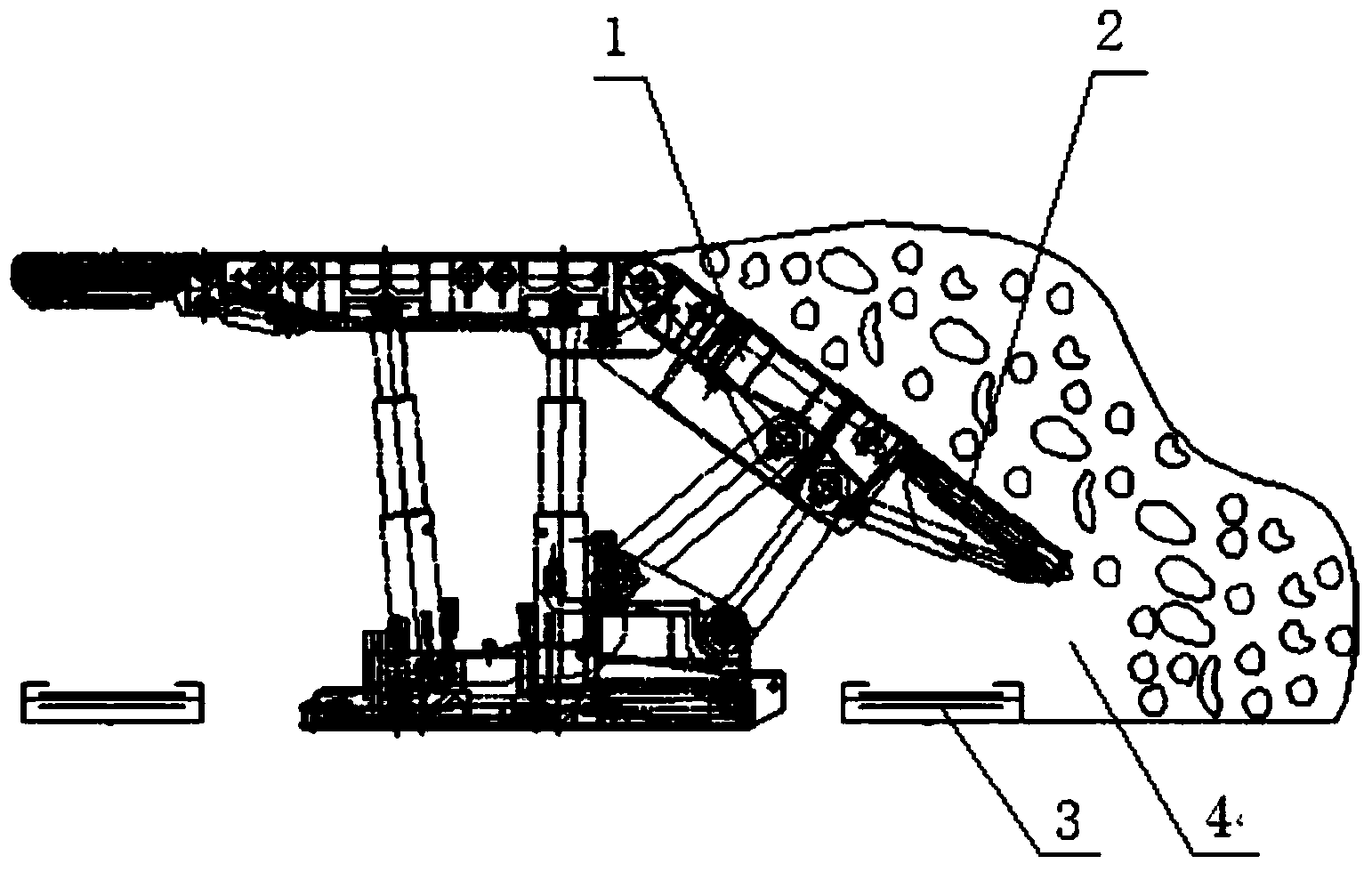

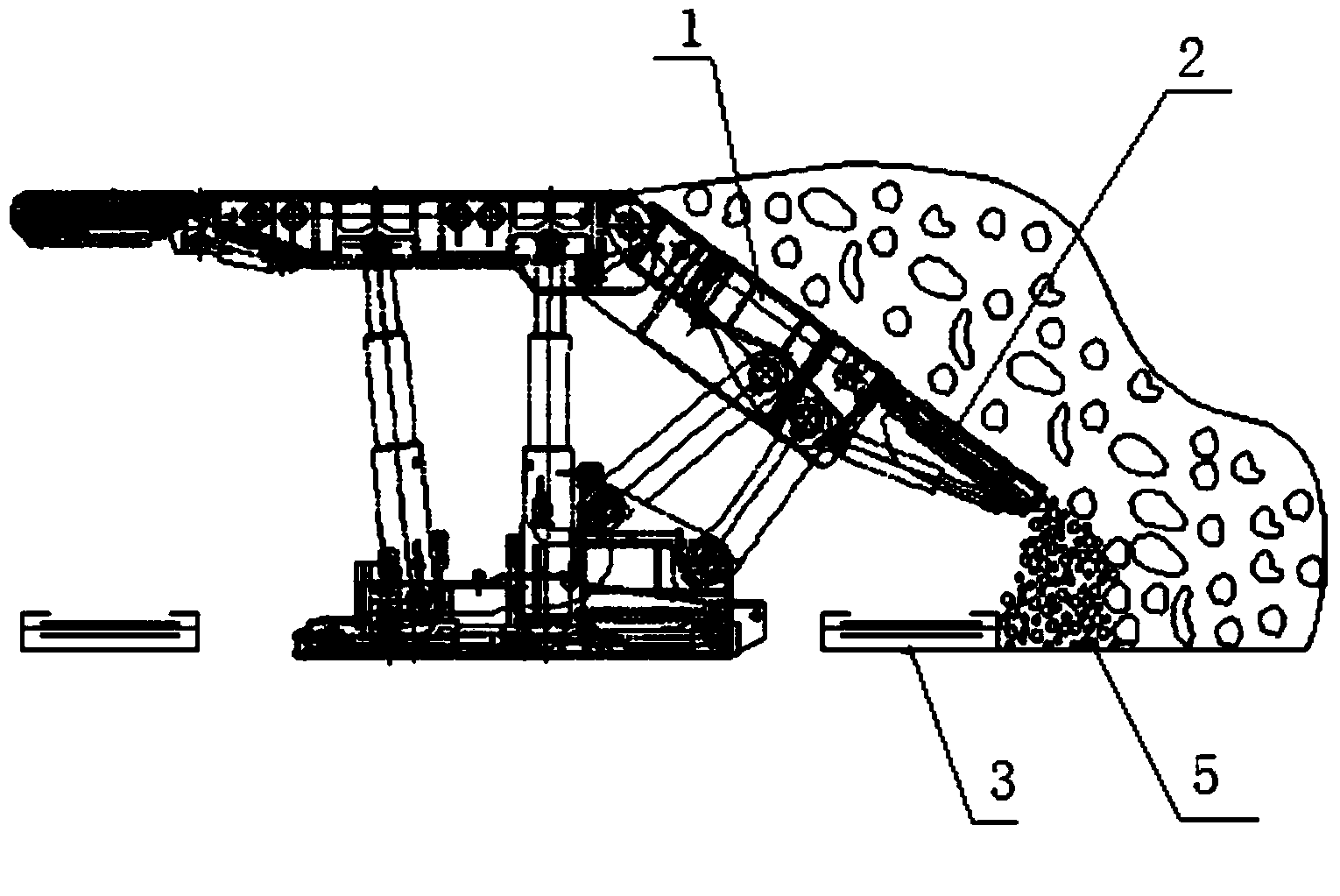

[0013] It is after putting the top coal and pulling the rear conveyor 3 in the last cycle (such as figure 2 shown), when entering the next cycle of top-coal caving, first operate the tail beam inserting plate 2 of the fully-mechanized caving support, so that the broken gangue in the goaf falls from the back of the tail beam 1, and the fallen gangue is filled in the In the space 4 formed after the rear transporter 3 moves forward, treat that this space is filled with crushed gangue to form 5 naturally (as image 3 shown), then operate the tail beam 1 jack of the fully-mechanized caving support to make the tail bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com