Tunnel supporting structure across active fault

A technology of active faults and supporting structures, applied in tunnels, tunnel linings, shaft linings, etc., can solve the impact of construction safety on lining strength and stability, can not fully exert the self-supporting capacity of surrounding rock, and affect lining strength and stability etc. to achieve good tensile-extrusion damage resistance, good resistance to fault creep and dislocation damage, and good shear damage resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

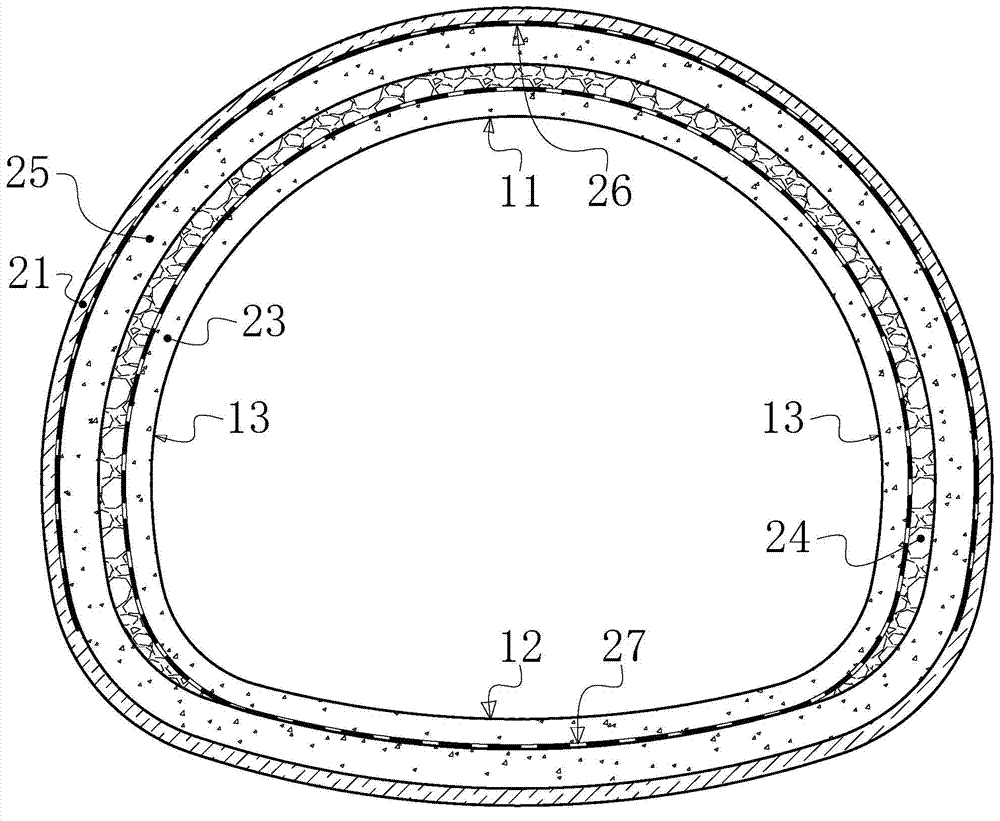

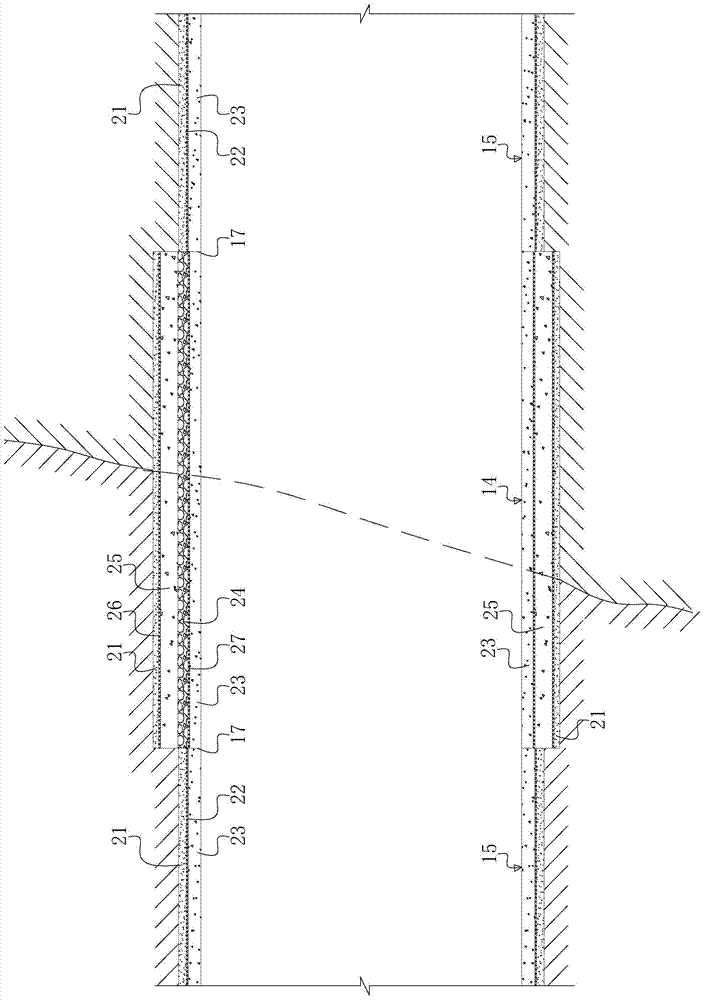

[0018] Such as figure 1 , figure 2 As shown, the tunnel support structure spanning active faults of the present invention includes a vault 11, an inverted arch 12, and two side walls 13 along the tunnel ring direction, and includes a fault spanning section 14 and a fault spanning section 14 axially along the tunnel longitudinal direction. The ordinary support section 15 connected to both ends; the ordinary support section 15 adopts a composite lining structure, including the primary support 21 on the radial outside, the secondary lining 23 on the radial inside, and the primary support 21 and The waterproof layer 22 between the secondary lining 23; along the radial direction of the tunnel, the fault spanning section 14 is respectively provided with a secondary lining 23, a foam concrete layer 24, and an initial support 21 from the inside to the outside...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com