An underground trackless rubber wheel vehicle exhaust gas collecting and discharging device

A technology of trackless rubber-tyred vehicles and rubber-tyred vehicles, which is applied in the direction of exhaust devices, noise reduction devices, engine components, etc., can solve the problems of underground air pollution and other problems, and achieve the effect of reducing pollution and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

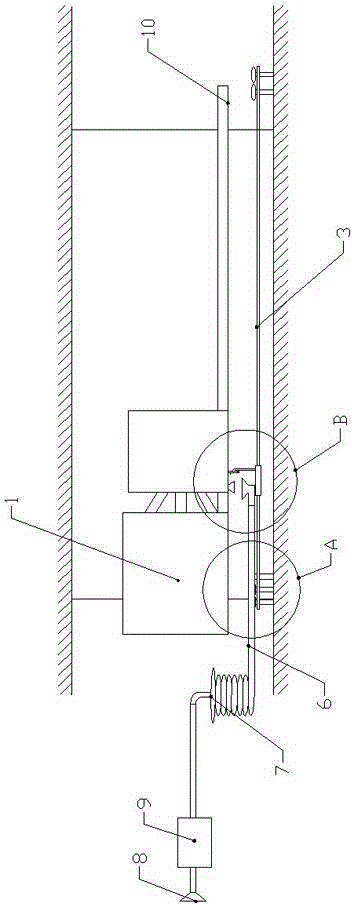

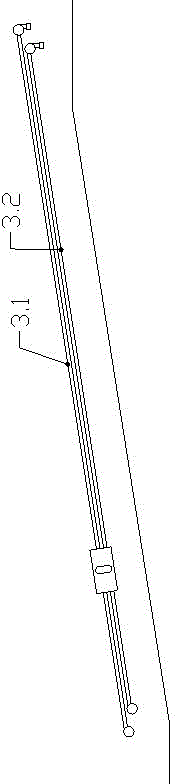

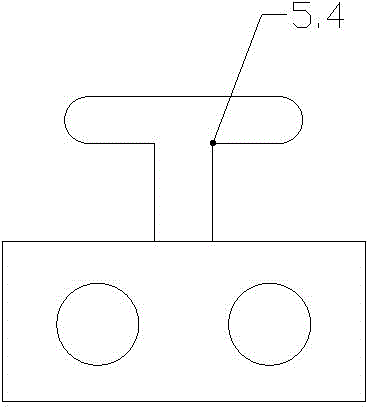

[0031] Such as figure 1 , 2 , 3, 4, 5, 6, 7, 8, and 9, an underground trackless rubber-tyred vehicle exhaust gas collection and discharge device includes a rubber-tyred vehicle 1 that travels in the underground exhaust gas collection and discharge section and has a tail gas discharge port 2, A wire rope conductor 3 is arranged on the roadway wall between the starting point and the end point of the exhaust gas collection section, and a sliding lock 4 capable of sliding is set on the wire rope conductor 3, and the sliding lock 4 is stuck on the An air collection hood 5 corresponding to the exhaust outlet 2 of the rubber-wheeled vehicle 1 is installed, and the air collection hood 5 communicates with an air duct 6, and the air duct 6 communicates with an exhaust pipe arranged in the return air lane. Port 8 communicates, and the rubber-tyred vehicle in front of the exhaust gas discharge port 2 is provided with a push frame 11 connected with the sliding lock 4, and the sliding lock...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com