Front end PTO structure on a diesel engine

A diesel engine and power output technology, which is applied in the field of front-end power output structure and front-end full power output structure, can solve the problems of increasing power output requirements, inability to meet high power output, and affecting the working life of the belt, and achieve output High power, easy to disassemble, and reduce design and production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with specific drawings.

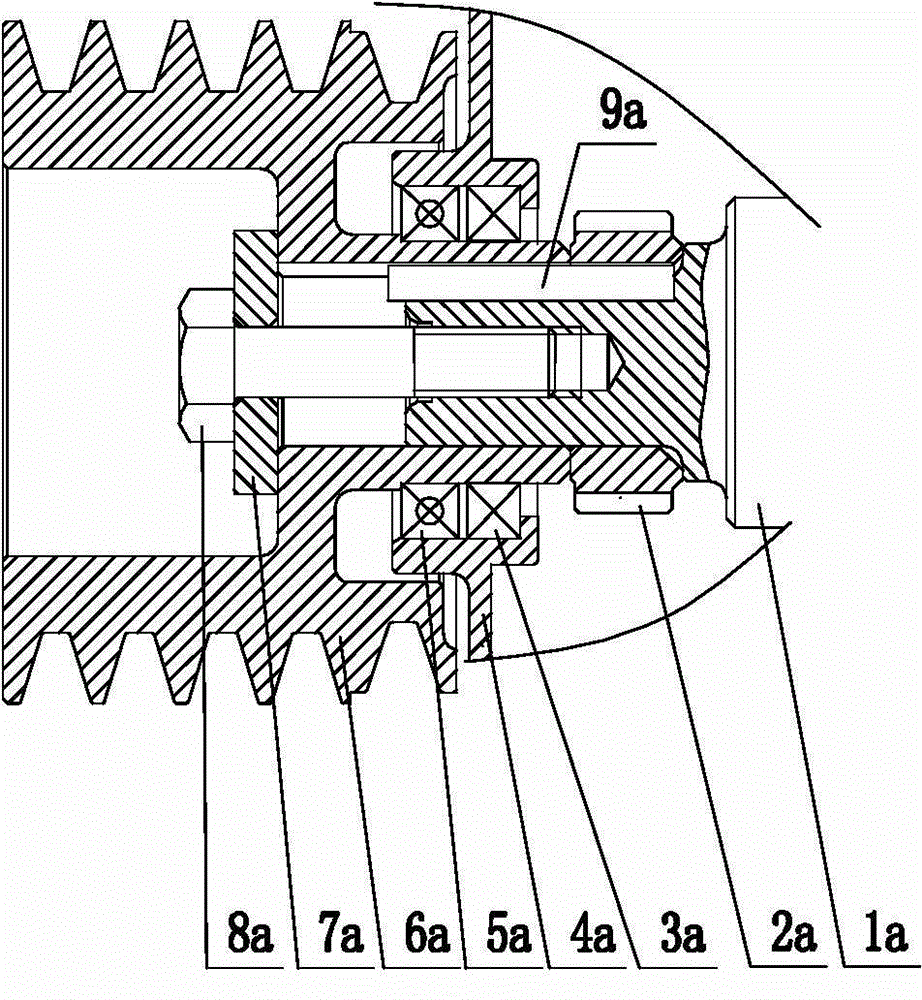

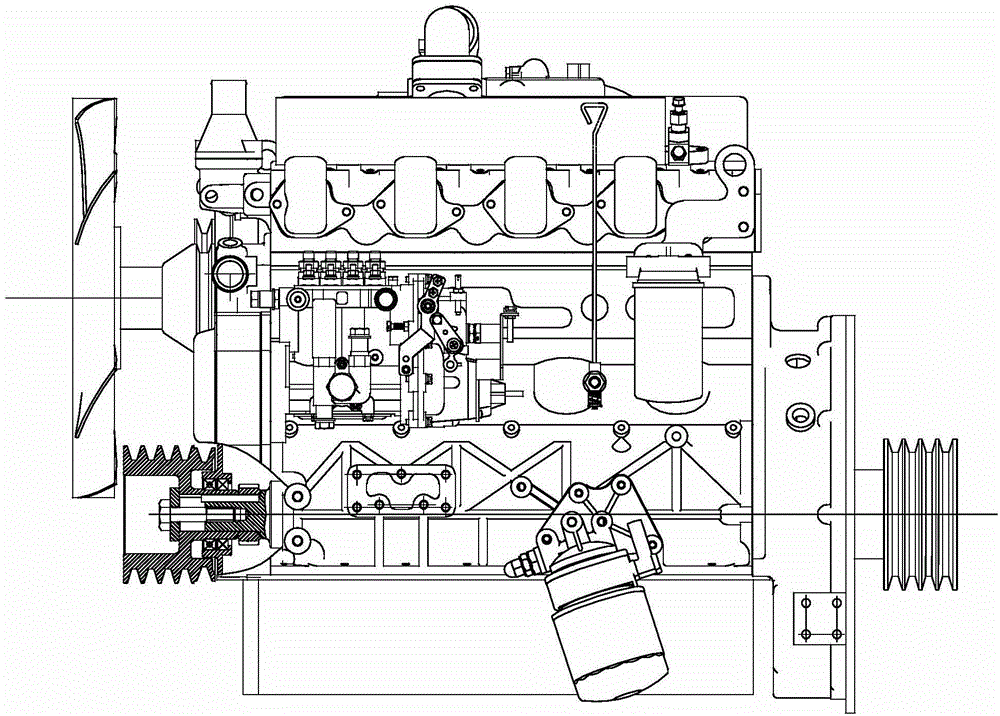

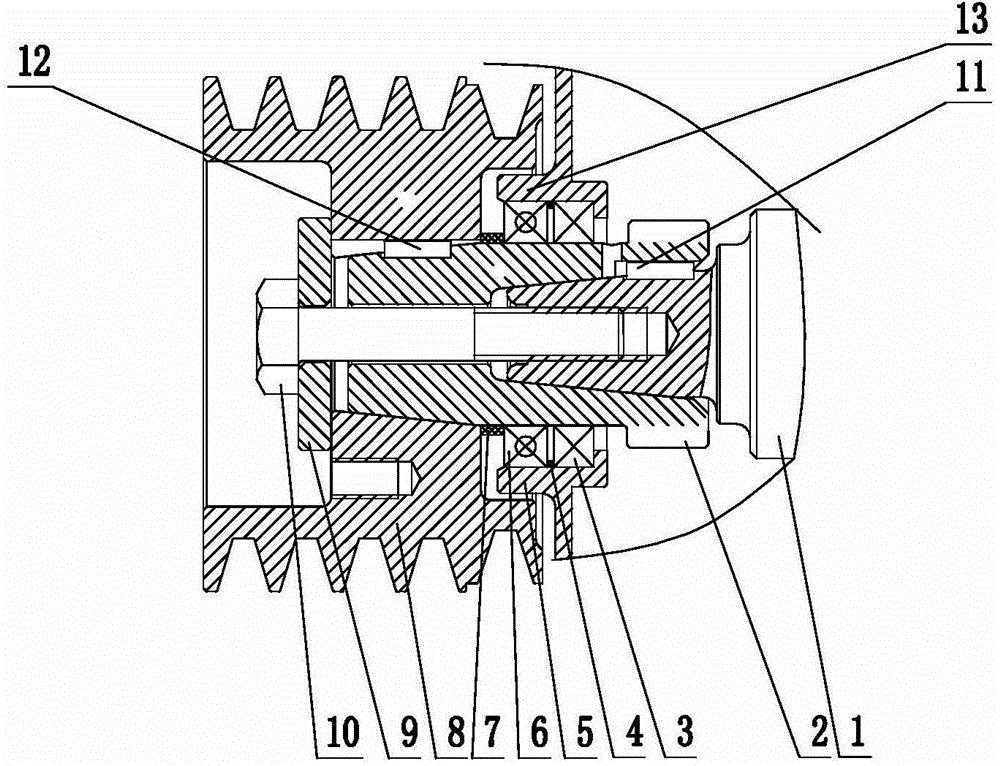

[0026] Such as Figure 3 ~ Figure 6 As shown: the front end power output structure on the diesel engine includes crankshaft 1, crankshaft timing gear 2, tapered shaft 2-1, ring gear 2-2, front end oil seal 3, spacer ring 4, gear chamber cover 5, front end Bearing 6, rubber sleeve 7, crankshaft pulley 8, start bolt pressure plate 9, start bolt 10, first flat key 11, second flat key 12, extension 13, cooling hole 14, through hole 15, etc.

[0027] Such as image 3 As shown, the present invention comprises the crankshaft 1 that is fixed on the diesel engine block, and the crankshaft timing gear 2 is set by the first flat key 11 at the front end of the crankshaft 1; Figure 5 As shown, the crankshaft timing gear 2 includes a tapered shaft 2-1, one end of the tapered shaft 2-1 is a large end, and the other end is a small end, and the small end of the tapered shaft 2-1 extends out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com