Fan blade wheel

A wind impeller and fan technology, applied in the direction of mechanical equipment, machines/engines, liquid fuel engines, etc., can solve the problems of not effectively improving the aerodynamic performance and acoustic indicators of the fan, increasing the manufacturing cost of the ribs, and increasing the centrifugal force of the blades, etc. , to achieve the effects of increasing the effective work area, promoting stability, and a reasonable center of gravity position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

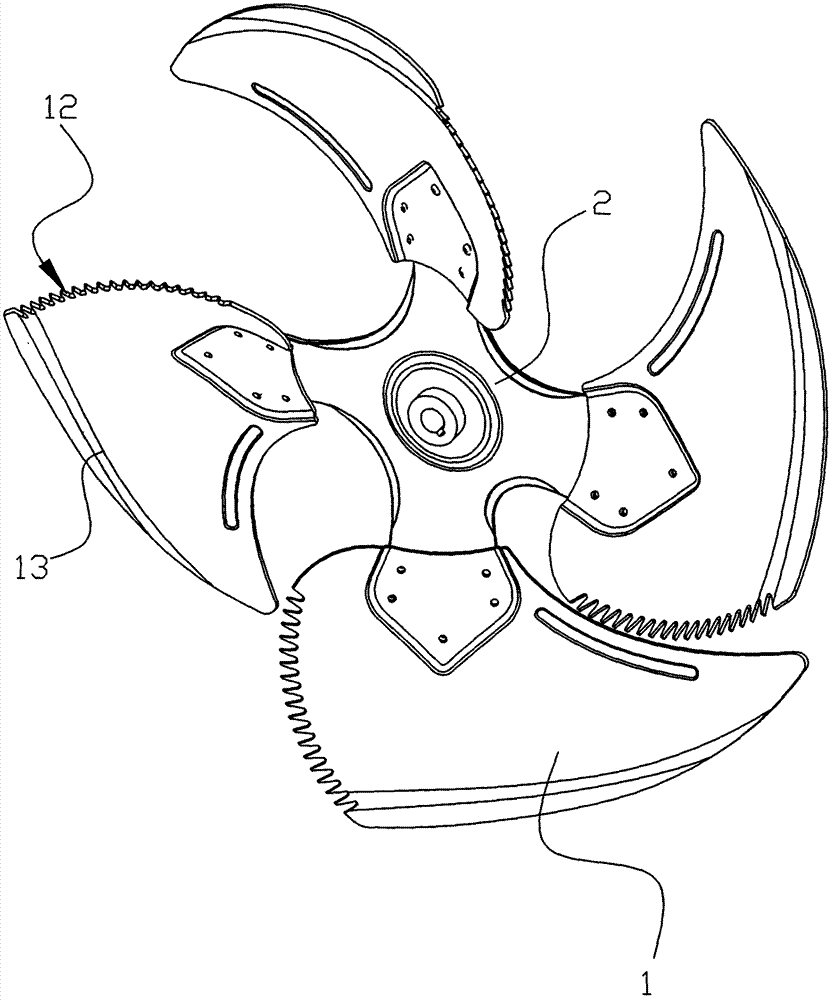

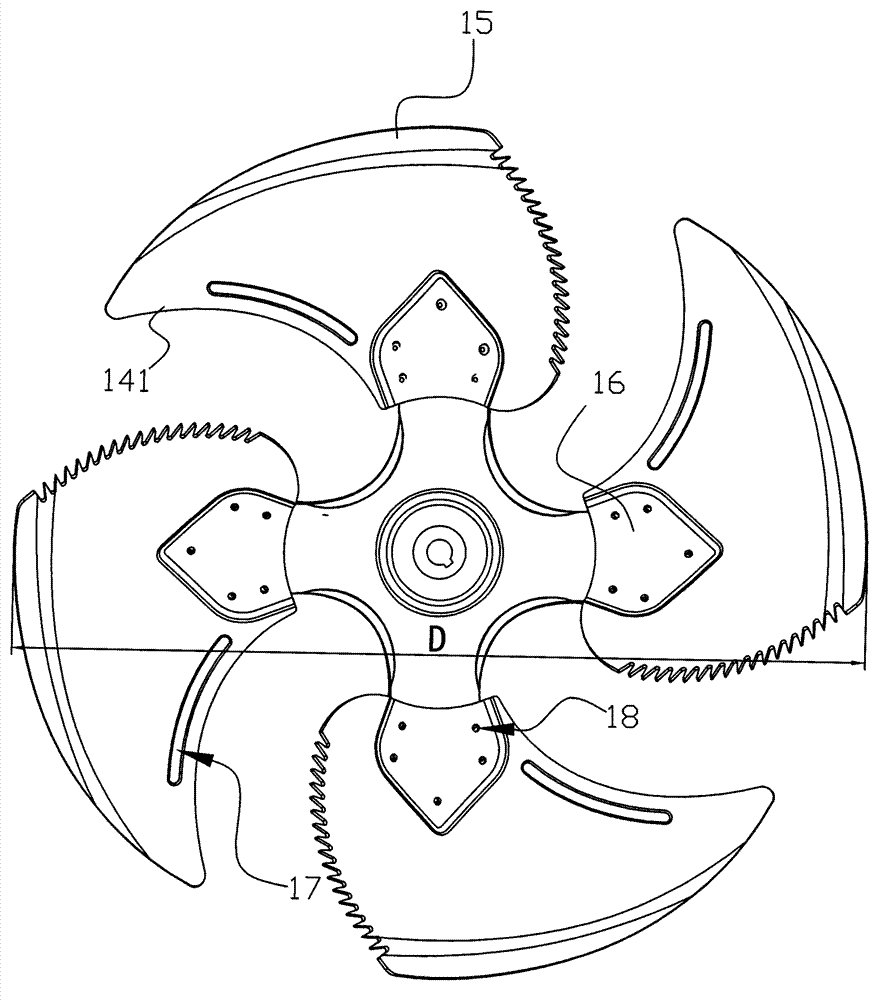

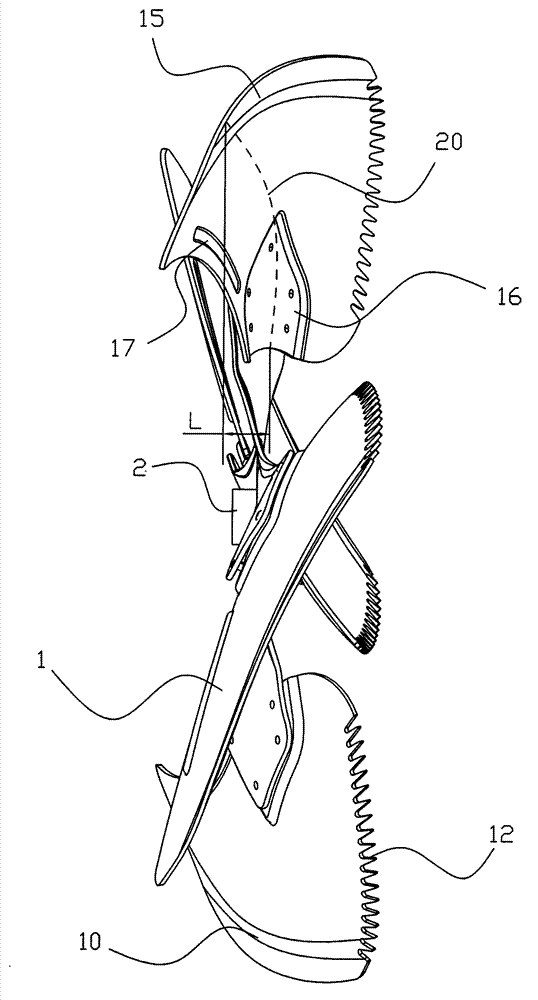

[0025] Such as Figure 1 to Figure 8 As shown, the wind impeller of the fan in this embodiment includes a blade 1 and a hub 2 linked with the output shaft of the motor. The blades 1 are distributed on the hub 2, and each blade 1 has an outer chord 13 wide and an inner chord 14 is narrow, and a streamlined flap 15 is provided on the blade 1 at the position of the outer chord 13, and the flap 15 extends to the outer chord 13 from the position where the blade tip extends into the outer chord 13 by 3%-30% of the length At the rear end, the trailing edge 12 of each blade 1 adopts a zigzag shape that can reduce rotational noise, and the outlet end of the blade 1 (ie, the trailing edge 12) is toothed, and the number of teeth adopts a prime number. The vortex flow loss at the outlet of the blade 1 is effectively reduced, the operating condition is re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com