Device and method for connecting brake pipe systems of railway freight cars

A connecting device, a technology for railway freight cars, applied in the direction of adjustable connection, flange connection, pipe/pipe joint/pipe fitting, etc., can solve the problem of normal use of the vehicle, failure of the brake pipe seal, leakage at the connection of the brake pipe system, etc. problems, to avoid welding, reduce leakage, and reduce the difficulty of assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

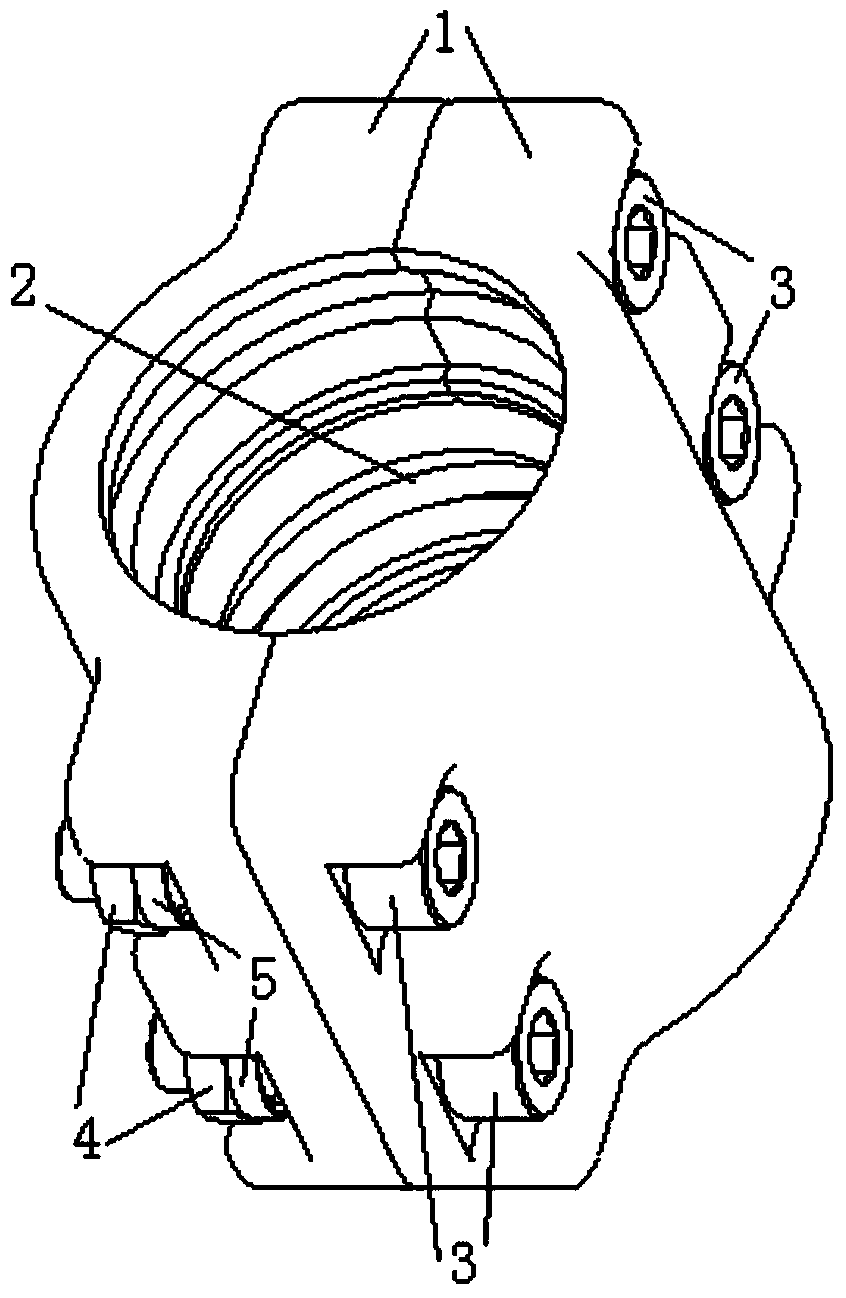

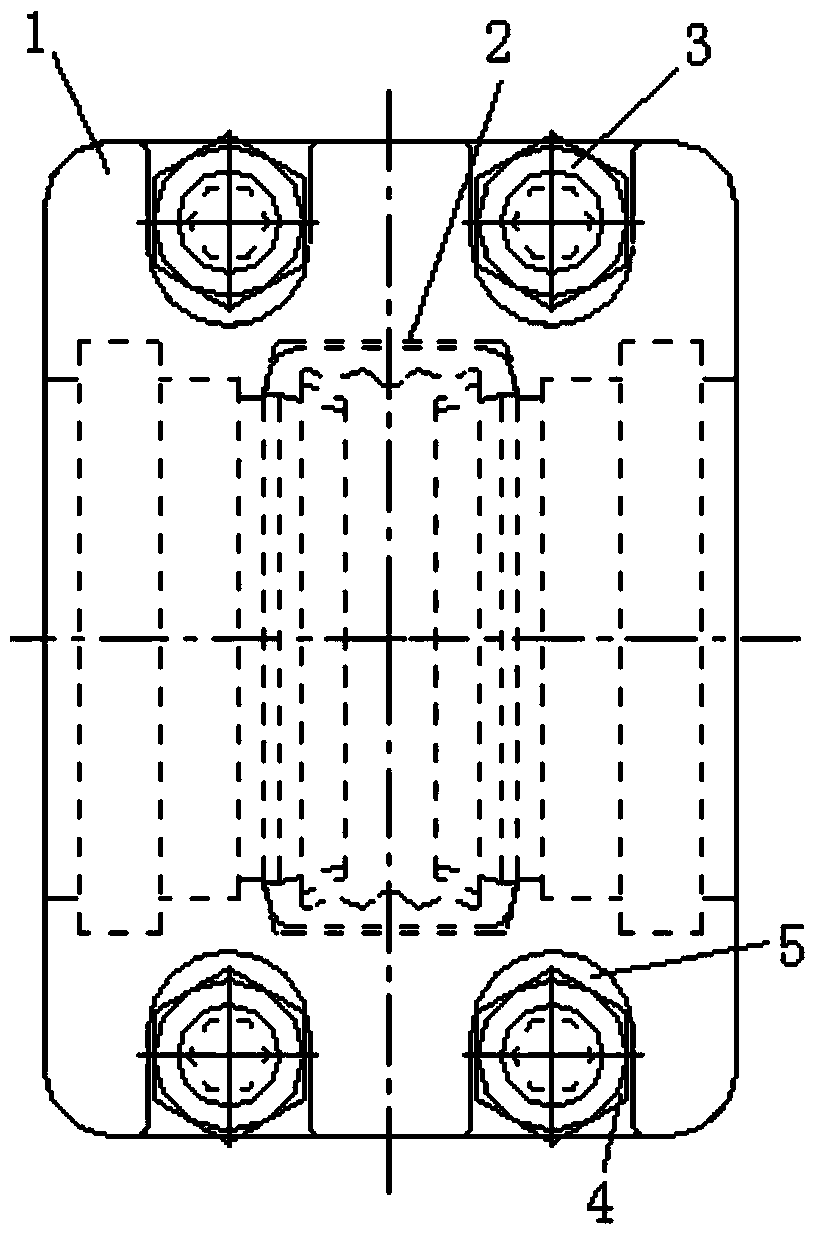

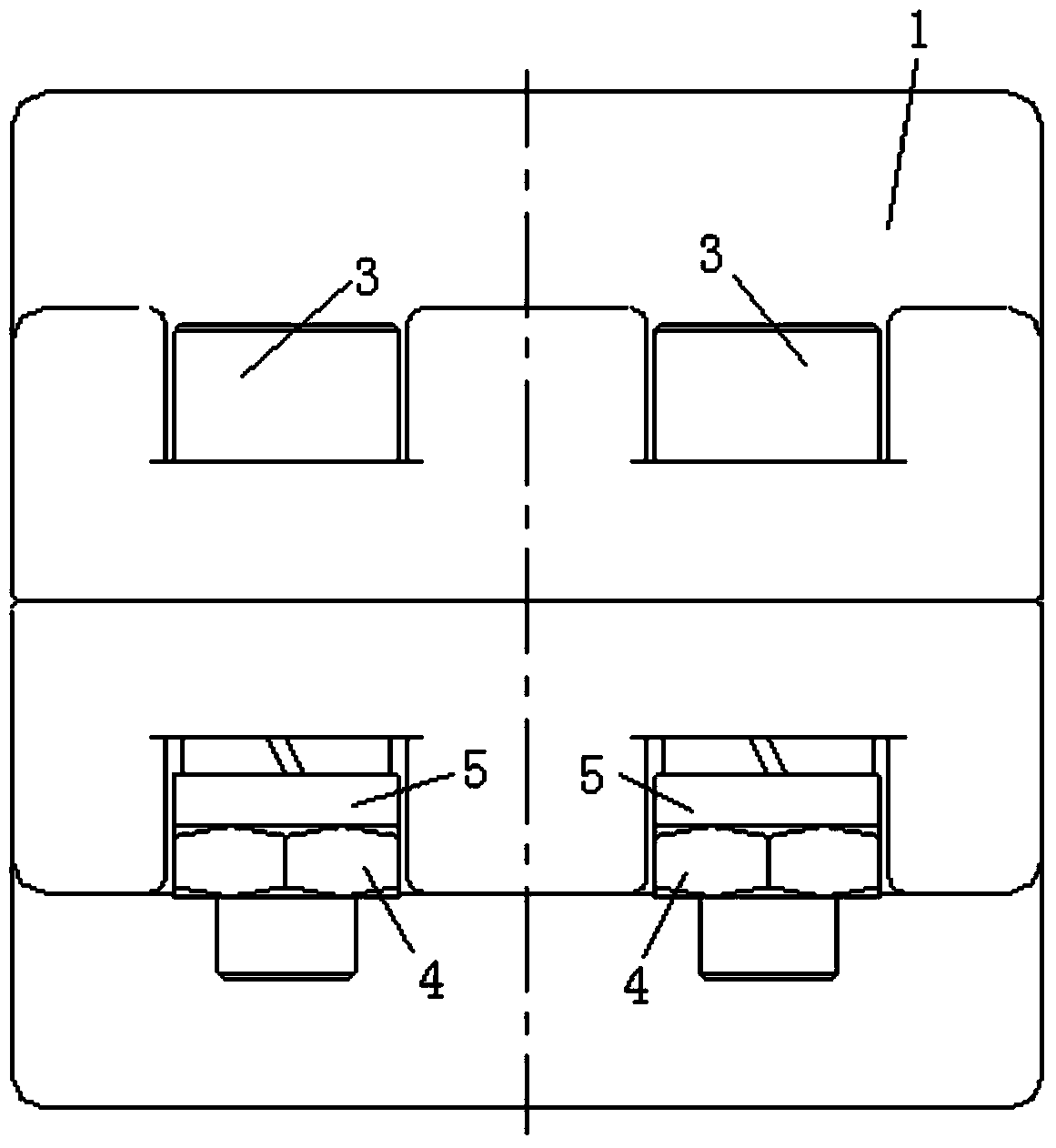

[0021] Such as Figure 1~4 As shown, the railway wagon brake piping connection device of the present invention includes two symmetrically arranged flange bodies 1 , a sealing ring 2 and several bolts 3 , nuts 4 and washers 5 . Two symmetrically arranged flange bodies 1 are fixedly connected together by several bolts 3 , nuts 4 and washers 5 , a cylindrical cavity is formed in the middle of the two flange bodies 1 , and a sealing ring 2 is arranged in the cylindrical cavity.

[0022] In the above embodiment, if Figure 5-7 As shown, each flange body 1 adopts a semicircular connecting piece with wings, and the middle part of the flange body 1 is provided with a sealing groove 11 for placing the sealing ring 2; both sides of the sealing groove 11 are provided with axial Width adjustment platform 12; the outside of the axial width adjustment platform 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com