Plate-fin heat exchanger

A heat exchanger, plate-fin type technology, applied in the field of heat exchangers, can solve the problems of high production and maintenance costs, inability to achieve one-time molding, complicated process, etc., to solve the problems of water resistance and air resistance, and solve the problem of air stagnation Phenomena, processing and making simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention. Of course, the described embodiments are only some of the embodiments of the present invention, not all of them. Based on The claims in the present invention, except for the embodiments but within the scope of the claims, also belong to the protection scope of the present invention.

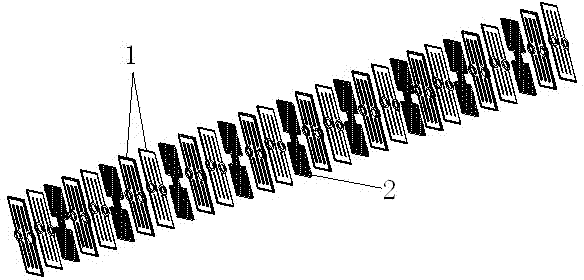

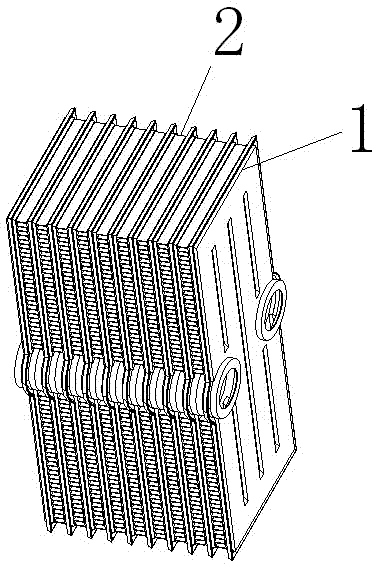

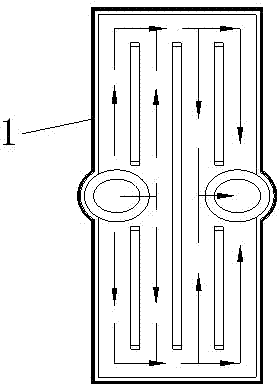

[0015] as attached figure 1 , figure 2 , image 3 Figure 4 , Figure 5 As shown, the main structure of the present invention is basically two parts: plate 1 and fin 2 (the main water inlet or water outlet is welded with pipe fittings or screw joints), and they are all stamped and formed. The plate is provided with water tanks and ribs. The two plates are superimposed in reverse to form a waterway; a fin is implanted between the stacked plate groups; holes are arranged on the plates...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com