Crimp terminal

一种压接端子、压接部的技术,应用在连接、导电连接、连接绝缘等方向,能够解决耐久性降低、联接部不能具有刚性、联接部损坏等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

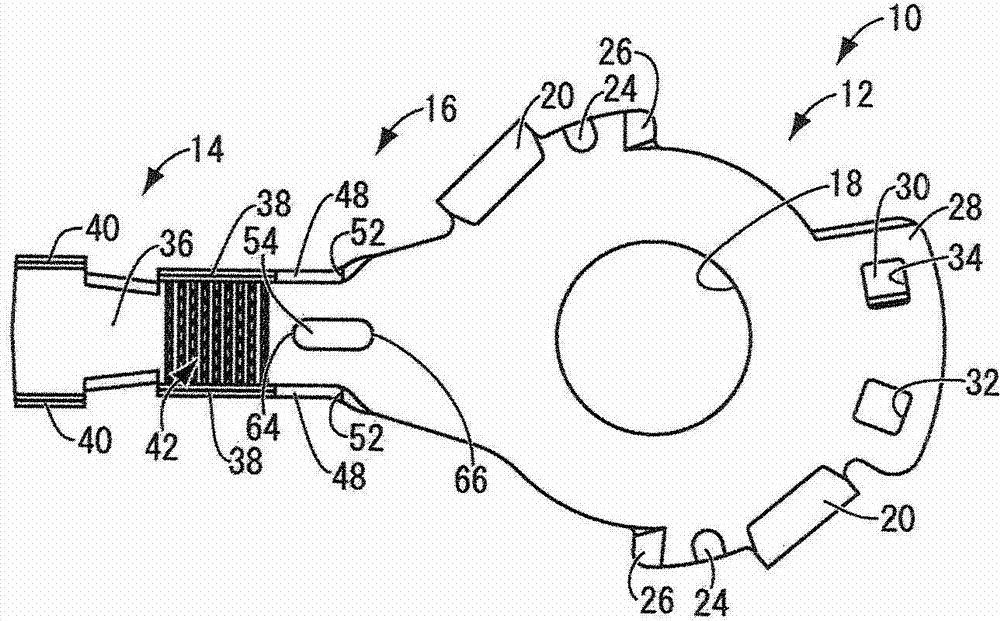

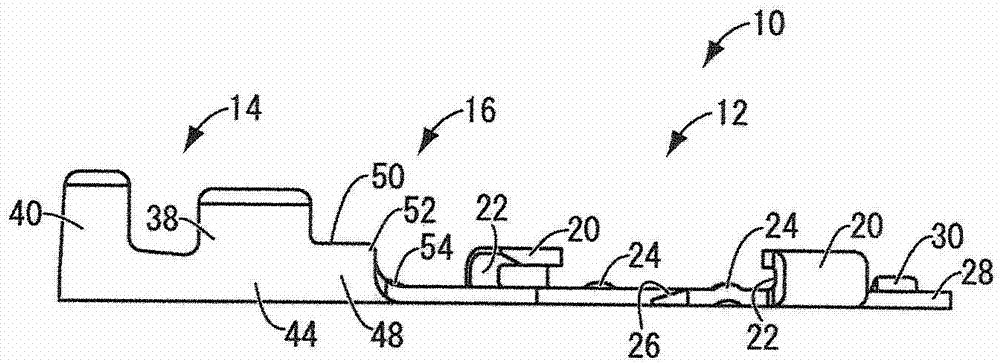

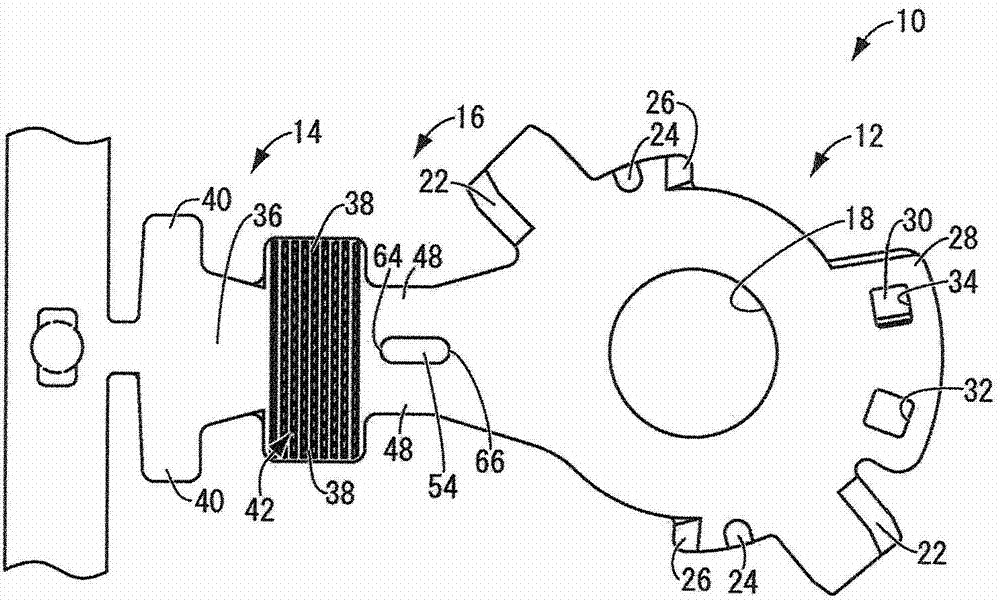

[0023] The crimp terminal according to the present invention consists of Figure 1 to Figure 5 Mark 10 in the mark. The crimp terminal 10 is integrally formed to include a connection portion 12 which is conductively connected to a connection object, a crimp portion 14 which has a function of being bonded by crimping onto a core wire 58 of a covered wire 56 The fixed core wire crimping portion 38, the coupling portion 16 extends between the connecting portion and the crimping portion.

[0024] The crimp terminal 10 is formed of, for example, a conductive metal capable of withstanding processes such as extrusion and punching, such as brass, copper, copper alloys, aluminum, and aluminum alloys. The crimp terminal 10 has a substantially uniform thickness as a whole.

[0025] The connection portion 12 has a substantially elliptical flat plate shape, and the through hole 18 passes through the center portion. The through hole 18 can accommodate a terminal bolt screwed into a prede...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com