Clamping device

A clamping device and clamping plate technology, applied in the direction of overhead lines/cable equipment, etc., can solve the problems of safety risks, increase of labor intensity of operators, hazards, etc., to improve safety, reduce labor intensity, and shorten operation time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The following will be described in conjunction with the accompanying drawings and a specific embodiment.

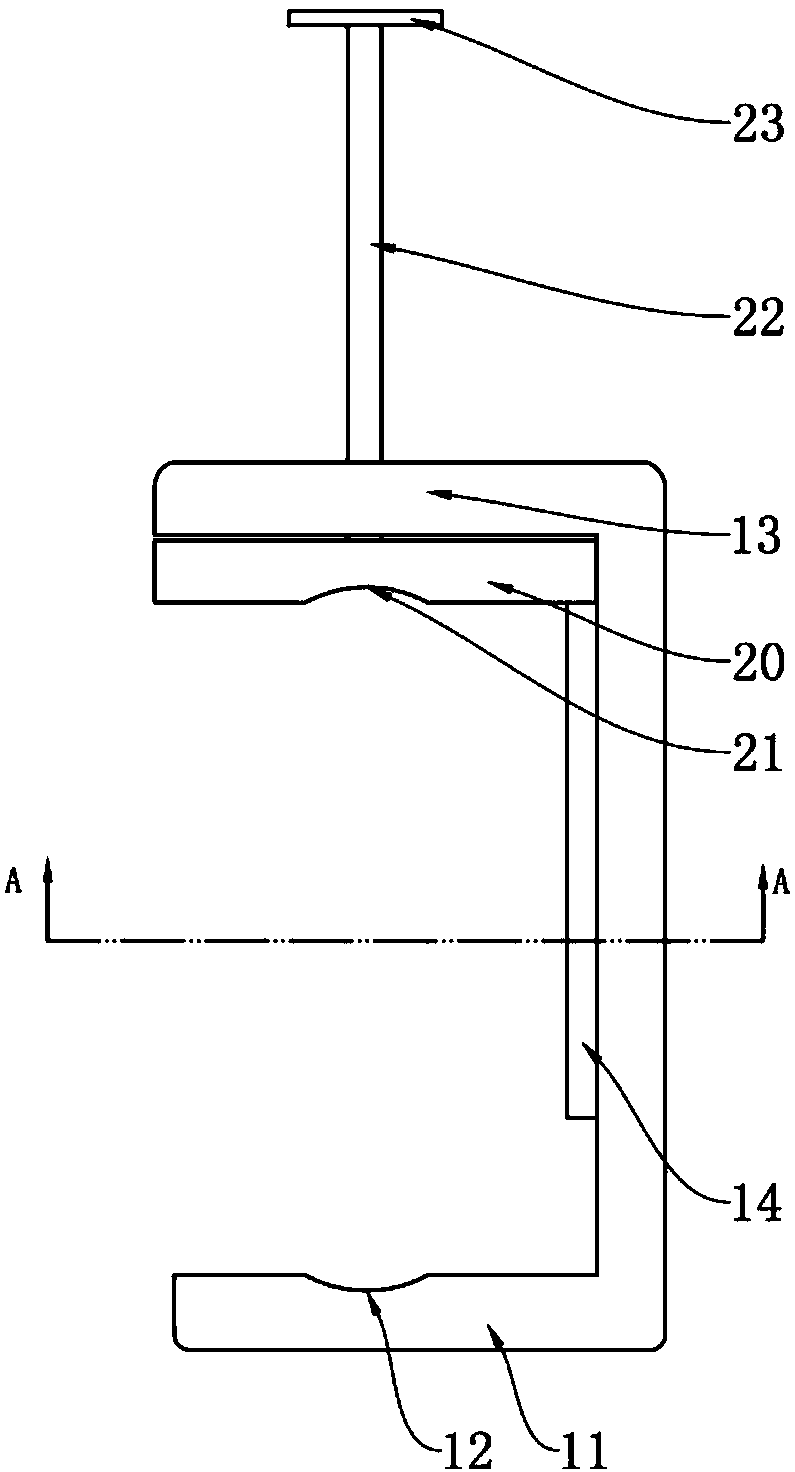

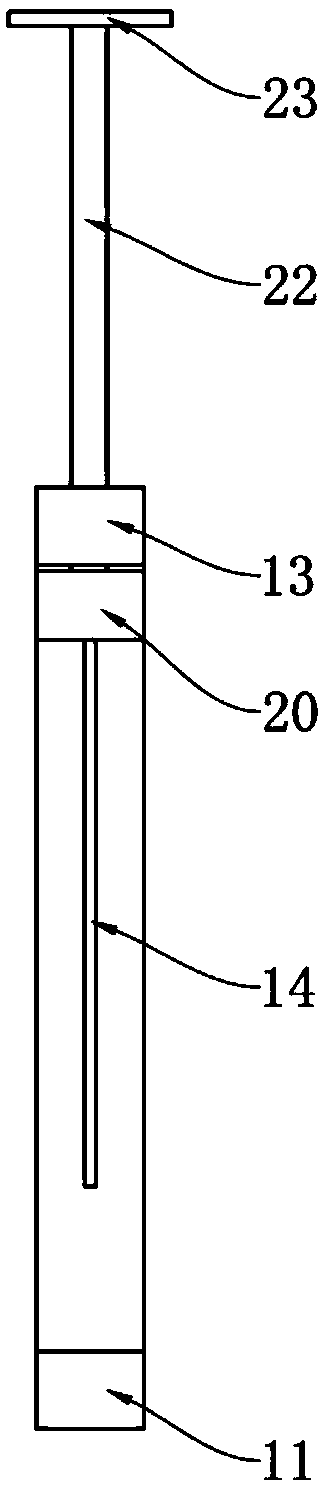

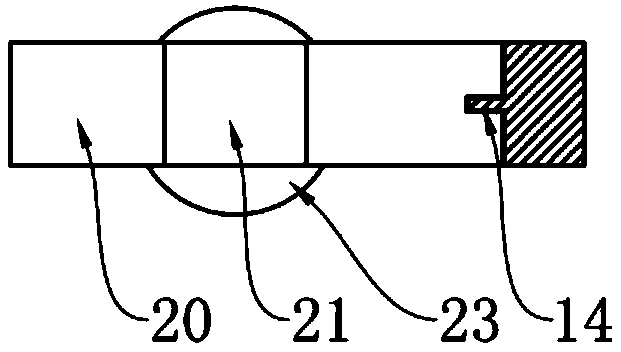

[0011] see Figure 1 to Figure 3 . Each component of the clamping device described in this embodiment is made of epoxy resin insulating material. Including a clamping frame 10 and a clamping plate 20, the clamping frame 10 is a concave frame, the concave frame, the concave frame is composed of a lower horizontal plate 11, an upper horizontal plate 13 and a connecting upper and lower horizontal plate Formed vertically.

[0012] The inner side of the clamping frame of the lower horizontal plate 11 is provided with a lower horizontal plate groove 12, the inner side of the clamping frame of the vertical plate is provided with a vertical guide rail 14, and the upper horizontal plate 13 is provided with a screw hole, which runs through the upper horizontal plate. The upper and lower surfaces of the horizontal board.

[0013] The clamping plate 20 is installed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com