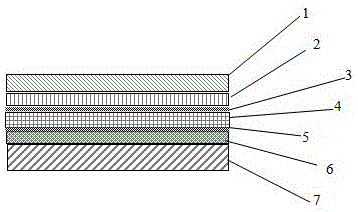

A lithium-ion battery core aluminum-plastic film made by hot-melt adhesive coating process

A lithium-ion battery and coating technology, which is applied to battery components, circuits, electrical components, etc., can solve the problems affecting the material's deep-drawing performance, appearance and anti-short circuit performance, inner polypropylene film aging, and electrolyte resistance Poor performance and other problems, to achieve the effect of excellent electrolyte corrosion resistance, high electrolyte corrosion resistance, and good cold stamping formability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1, configure the treatment solution according to the following formula: the chromium salt is potassium dichromate, and the mass percentage concentration in the mixed solution is 0.3%; the acid is hydrochloric acid, and the mass percentage concentration in the mixed solution is 4%; the fluoride is fluoride Potassium, the mass percent concentration in the mixed solution is 0.2%; the rest is pure water. Use this treatment liquid to process 40μm thick grade 8021 soft aluminum foil on the aluminum foil processing machine; the treated aluminum foil is coated with a layer of 4μm thick PP hot melt adhesive on the aluminum foil coating machine, and compounded with two-component polyurethane glue to 25μm in the dry process machine After the polyamide film and the aluminum foil coated with hot melt adhesive, the surface of the aluminum foil that is not coated with hot melt adhesive is the composite surface, and the thickness of the adhesive layer is 5 μm; the above-menti...

Embodiment 2

[0026] Embodiment 2, configure the treatment solution according to the following formula: the chromium salt is chromium oxide, and the mass percentage concentration in the mixed solution is 0.4%; the acid is boric acid, and the mass percentage concentration in the mixed solution is 8%; the fluoride is sodium fluoride in The mass percentage concentration in the mixed solution is 00.4%; the remaining components are pure water. Use this treatment liquid to process 40μm thick grade 8021 soft aluminum foil on the aluminum foil processing machine; the treated aluminum foil is coated with a layer of 4μm thick PP hot melt adhesive on the aluminum foil coating machine, and compounded with two-component polyurethane glue to 25μm in the dry process machine Polyamide film and aluminum foil coated with hot-melt adhesive, the surface of the aluminum foil not coated with hot-melt adhesive is the composite surface, and the thickness of the adhesive layer is 5 μm; the above-mentioned semi-finis...

Embodiment 3

[0027] Embodiment three, according to the following formula configuration treatment liquid: chromium salt is potassium chromate, and the mass percent concentration in the mixed solution is 0.5%; The acid is phosphoric acid, and the mass percent concentration in the mixed solution is 7%; Fluoride is potassium fluoride The mass percent concentration in the mixed solution is 0.5%; the rest is pure water. Use this treatment solution to process 40 μm thick grade 8021 soft aluminum foil on the aluminum foil processing machine; use two-component polyurethane glue to compound 15 μm thick polyamide film and treated aluminum foil in the dry process machine, and the thickness of the glue layer is 5 μm; the surface of the above-mentioned semi-finished aluminum foil is The AC gluing part of the extruder is directly coated with PP hot melt adhesive, the thickness of the coating is 3μm, and the finished product can be obtained by pouring a heat-sealing layer on the glue surface after coating....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com