Swivel cab

A driver's cab and rotary technology, which is applied in the direction of mechanical equipment, load suspension components, gear transmissions, etc., can solve the problems of manufacturing personnel difficulties, increase production costs, etc., and achieve the effects of simple structure, extended service life, and simple maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

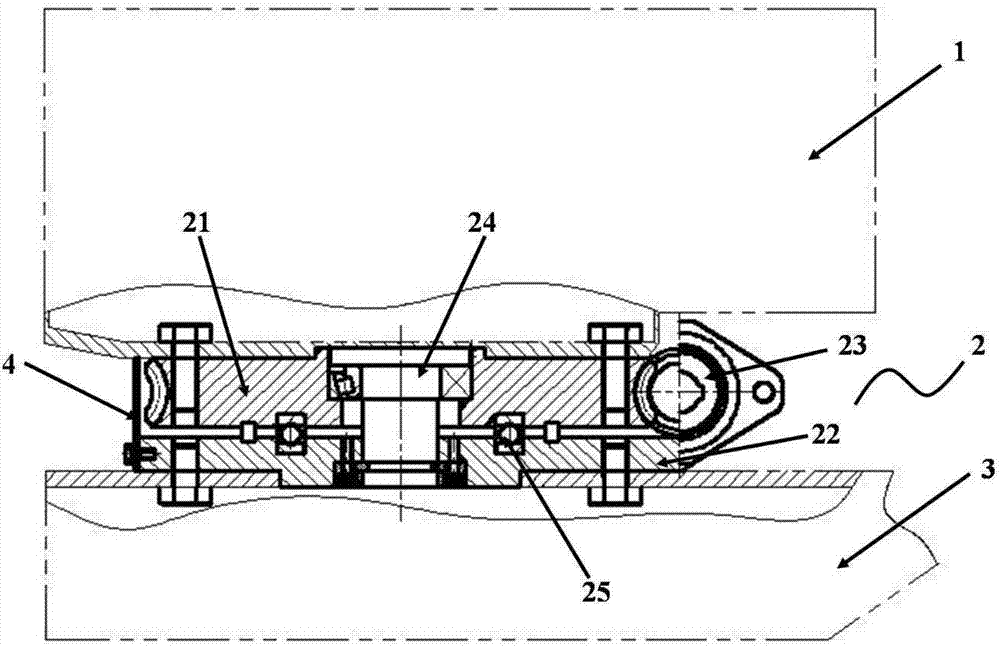

[0028] Such as figure 1 , 2 As shown, this embodiment provides a rotary driver's cab, including a driver's cab 1, a rotary drive device 2 located below the driver's cab 1, and a bracket 3 below the rotary drive device 2;

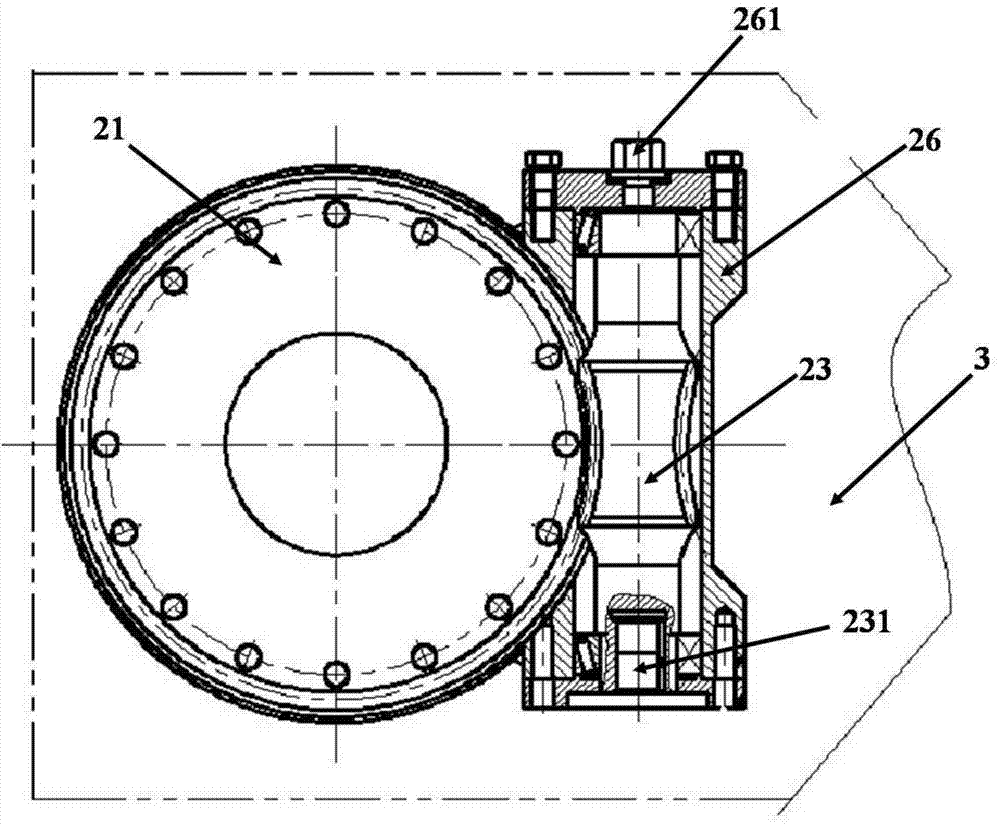

[0029] The rotary driving device 2 includes a worm wheel 21, a lower support 22 and a worm screw 23, the worm wheel 21 and the lower support 22 are connected by a central shaft 24, and the central shaft 24 passes through the first shaft hole at the center of the worm wheel 21 In the second shaft hole at the corresponding position of the lower support 22, the bottom surface of the worm wheel 21 and the top surface of the lower support 22 are parallel to each other, and there is a thrust force between the worm wheel 21 and the lower support 22. The ball bearing 25 avoids direct friction between the lower surface of the worm wheel 21 and the upper surface of the lower support 22;

[0030] The worm 23 is located in the installation groove 26 on the right side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com