Method for manufacturing solid block by using engineering waste, solid block, and backfilling method

A technology of solid blocks and waste materials, applied in the field of solid blocks, can solve problems such as environmental damage, environmental damage, and occupation of land resources, and achieve the effects of avoiding environmental pollution, avoiding waste, and avoiding environmental damage caused by waste materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manners of the present invention will be further described in detail below.

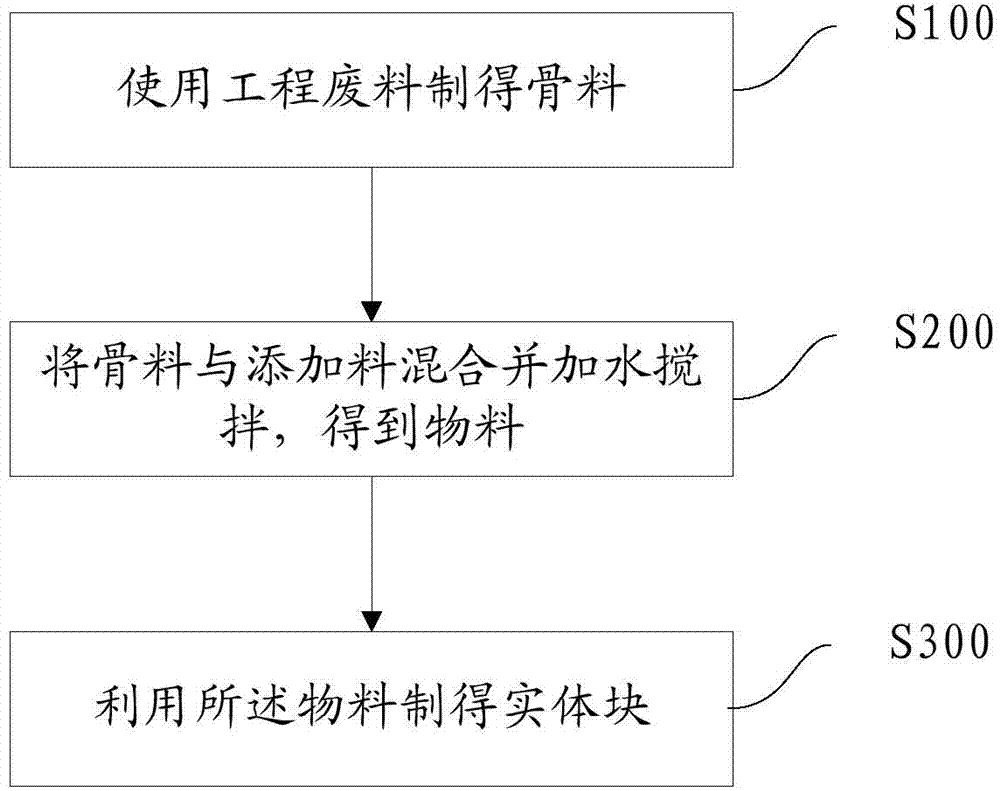

[0031] figure 1 It is a flow chart of the method for manufacturing a solid block from engineering waste according to the present invention. The method for manufacturing a solid block from engineering waste disclosed in the present invention includes the following steps S100, S200 and S300.

[0032] S100. Using engineering waste to produce aggregate, wherein the engineering waste includes construction waste and / or industrial and mining waste.

[0033] Preferably, the industrial and mining waste in the present invention includes at least one of ore powder, fly ash, coal gangue, and black sand. When the engineering waste includes large-sized construction waste or industrial and mining waste (such as construction waste, coal gangue, etc.), step S100 specifically crushes the enginee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com