Combined vortex type water heat power generation device

A technology of waste heat power generation and vortex

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

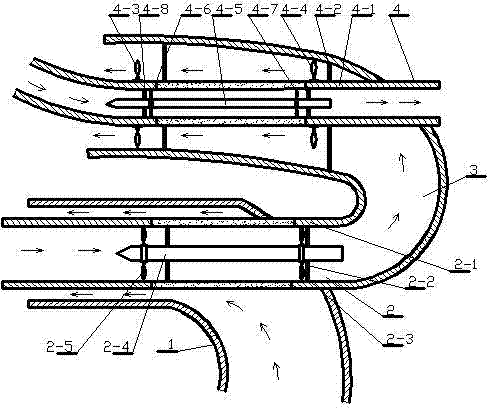

[0012] In the accompanying drawings, a combined vortex waste heat power generation device includes a waste heat exhaust pipe 3, and a primary power generation system 2 and a secondary power generation system 4 respectively connected to the waste heat exhaust pipe 3. The primary power generation system 2 There is a cylindrical intake pipe I2-1 passing through the cavity of the exhaust gas exhaust pipe 1, the middle part of the intake pipe I2-1 is provided with a central axis I2-4, and the central axis I2-4 is supported by a support rod I2-2 It is fixedly connected with the pipe wall of the intake pipe I2-1; the end of the central axis I2-4 located at the air inlet is rotatably connected with a turbofan I2-5, and the end of the central axis I2-4 located at the exhaust port is rotatably connected with a power generation fan I2-3; the exhaust port of the air intake pipe I2-1 is connected to the waste heat exhaust pipe 3; the secondary power generation system 4 is provided with a cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com