Waste heat utilization system and method suitable for fluctuating heat load

A heat load and waste heat technology, applied in the direction of heat exchangers, indirect heat exchangers, heat exchanger types, etc., can solve problems such as ineffective utilization, achieve the effects of avoiding heat dissipation loss, improving waste heat utilization efficiency, and meeting demand fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

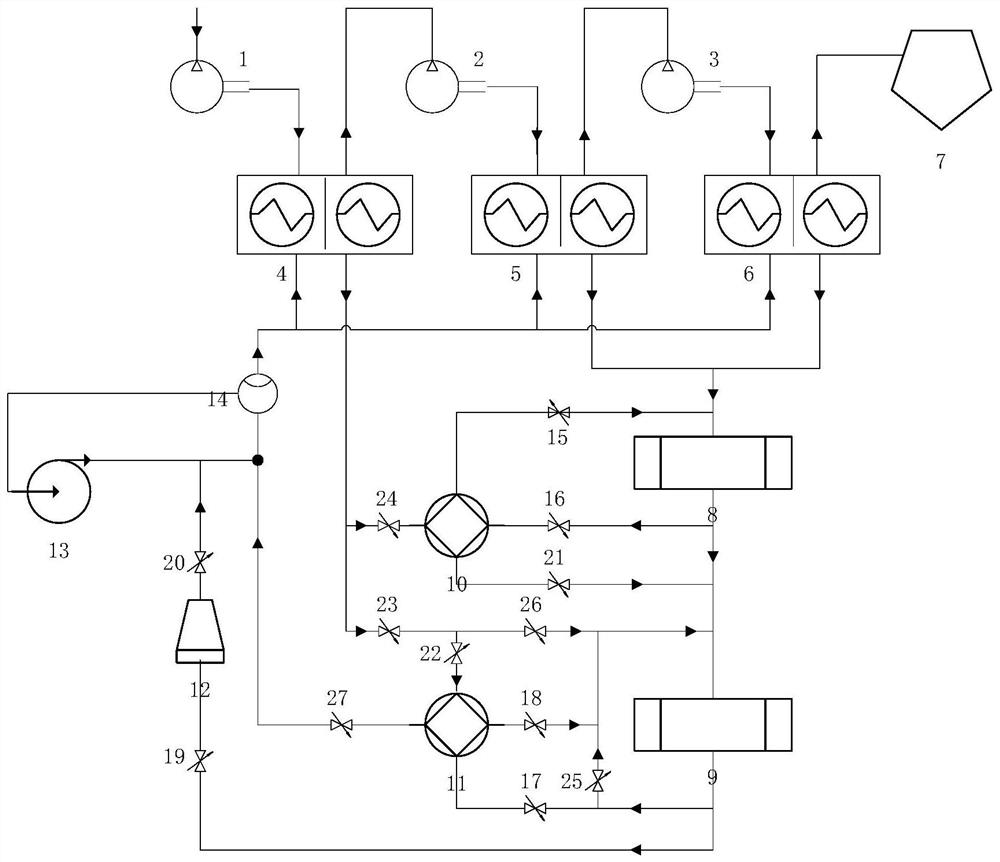

[0027] Applicable to waste heat utilization systems with fluctuating heat loads to realize waste heat utilization methods, including:

[0028] Maximum cooling capacity mode:

[0029] In the maximum cooling capacity operation mode, the switch valves 15, 19, 20, 21 are in the open state, the switch valves 18, 23, 26, 27 are in the closed state; the switch control valves 16, 24 are in the open state, and the switch control valves 17, 22 are in the open state. , 25 are in the closed state.

[0030] 150,000 Nm 3 / h The air at normal temperature and pressure reaches 95°C after being compressed by the first stage of the air compressor, and enters the first stage heat exchanger 4 to exchange heat with the cooling water at 35°C. After the heat exchange, the compressed air temperature is 40°C and enters the air compressor Two-stage compression, three-stage compression of the air compressor, the temperature of the second-stage compressed air and the third-stage compressed air can reach...

Embodiment 2

[0034] Applicable to waste heat utilization systems with fluctuating heat loads to realize waste heat utilization methods, including:

[0035] Maximum heat supply mode:

[0036] In the maximum heat supply operation mode, the on-off valves 18, 19, 20, 23, and 27 are in the open state, the on-off valves 15, 21 are in the closed state, and the on-off valve 26 is switchable; the on-off regulating valves 17, 22, and 25 are in the open state , the switch regulating valves 16, 24 are in the closed state.

[0037] 150,000 Nm 3 / h Normal temperature and normal pressure air passes through the first stage of the air compressor, and the temperature reaches 80°C, and enters the first stage heat exchanger 4 to exchange heat with 35°C cooling water. After the heat exchange, the compressed air temperature is 40°C and enters the air compressor Two-stage compression, three-stage compression of the air compressor, the temperature of the second-stage compressed air and the third-stage compresse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com