A kind of machine-made sand with tailings sand as the main raw material and its dry process

A technology of main raw material and tailings sand, applied in the direction of mixers with rotating stirring devices, mixers, chemical instruments and methods, etc., can solve the complex production process, high requirements for anti-vibration design of steel structures, and no production process control requirements Advanced issues, to achieve the effect of protecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Sand making building project of a company in Jiangsu

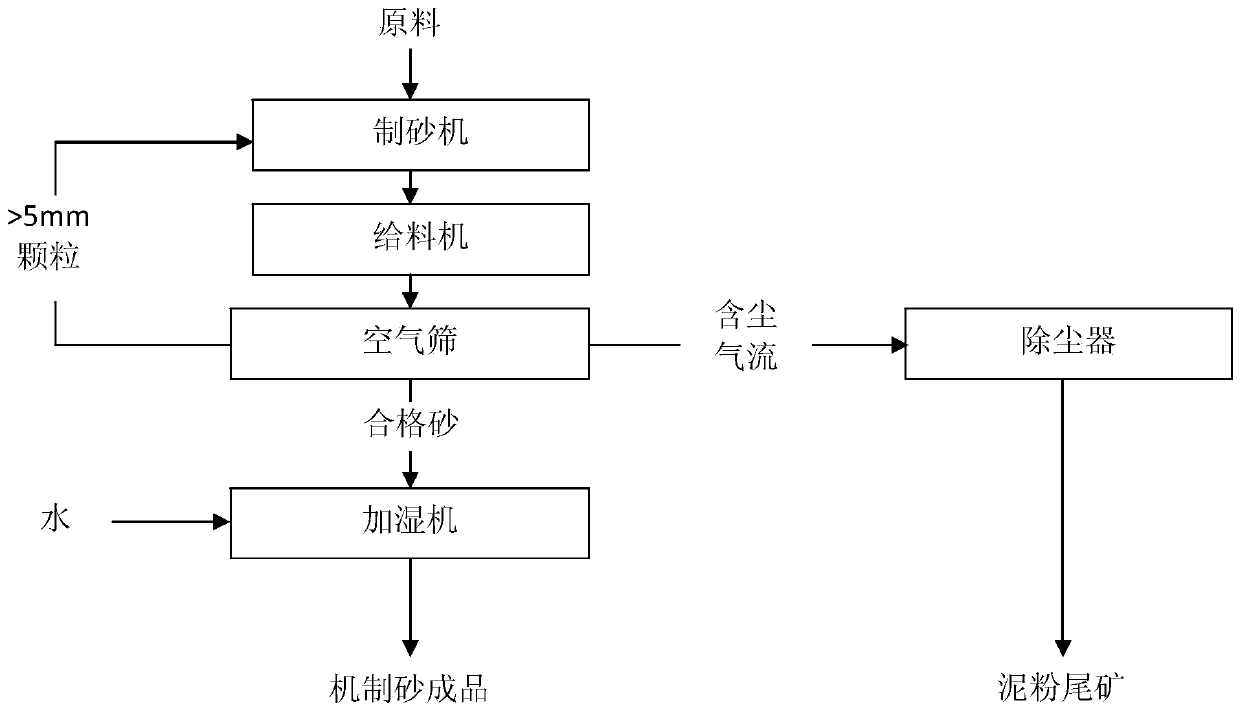

[0045] The company is located in Zhenjiang, Jiangsu, and the raw material is limestone. The company has an annual output of nearly 2 million tons of tailings sand. Due to limited use, it has been mainly accumulated in the goaf of the company for a long time. In 2016, based on the market demand and the characteristics of the sand making system, the company chose the SCM-200 sand making building developed according to this process, and adjusted the parts according to the market conditions and raw material characteristics. The sand making machine adopts the rotor as the Three-channel structure, the vibrating screen is a two-layer screen with 3mm mesh and 5mm mesh, the raw material is a mixture of 90% tailings sand and 10% 5-16mm crushed stone, and the hourly processing capacity is 200 tons, of which sand making products are 170 Ton. process such as image 3 Shown:

[0046] The basic parameters of raw materials and ...

Embodiment 2

[0051] A construction stone mine sand building project in Hubei

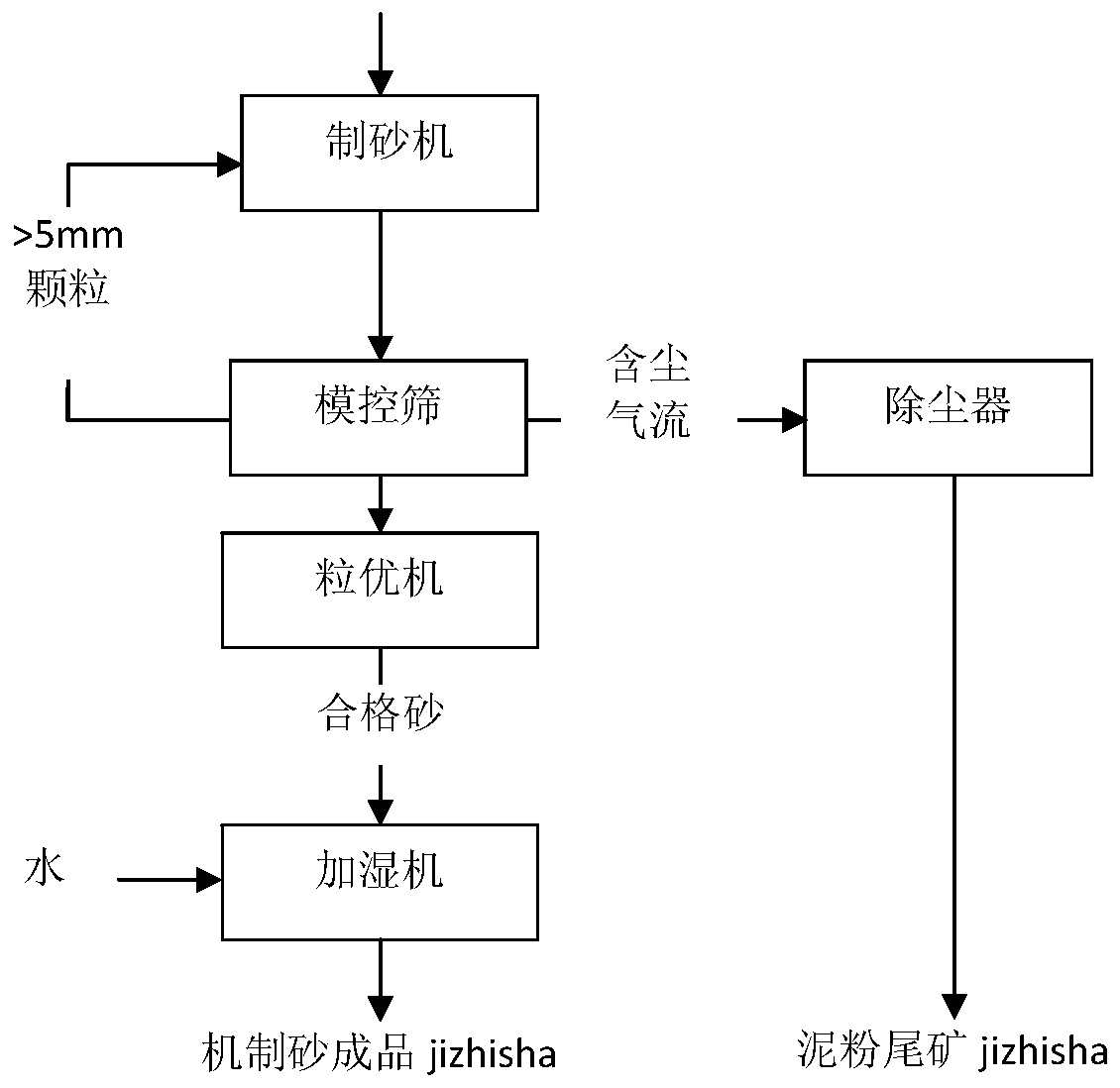

[0052] The company is located in Xianning, Hubei, and the raw material is limestone. The company produces nearly 1 million tons of tailings sand per year, part of which was stored in the mine stope in the early stage, and most of it was sold at a low price as roadbed material, which seriously affected the company's profitability and the level of resource utilization was relatively low. In 2016, based on the market demand and the characteristics of this sand making system, the company selected the SCM-150 sand making building developed according to this process relatively completely. The bottom screen of the vibrating screen has an aperture of 2.5mm, and the raw materials are all mine tailings. The hourly processing capacity is 150 tons, including 130 tons of finished machine-made sand. System layout such as Figure 4 :

[0053] The basic parameters of raw materials and the test results of finished products ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com