Bionic erosion-resisting pipeline elbow

A pipeline elbow, erosion-resistant technology, applied in the field of chemical engineering, can solve problems such as difficulty in obtaining ideal results, and achieve the effects of enhancing corrosion resistance, protecting walls, and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

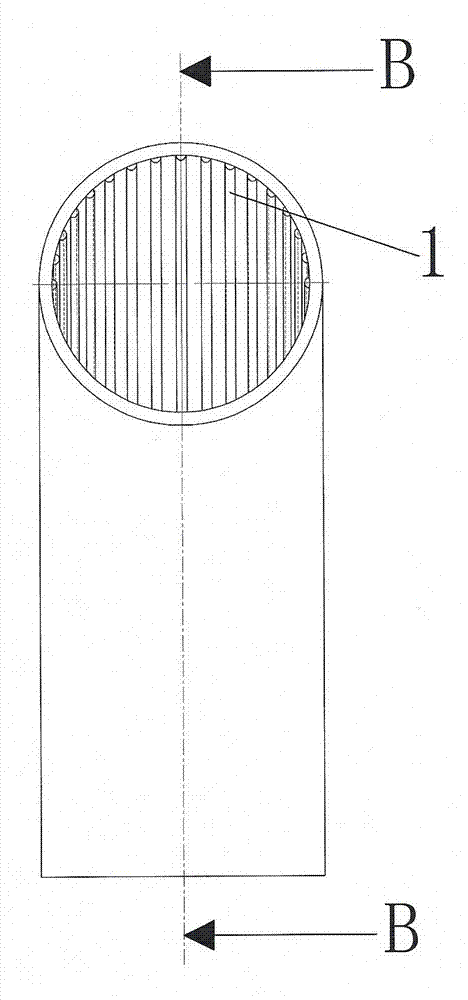

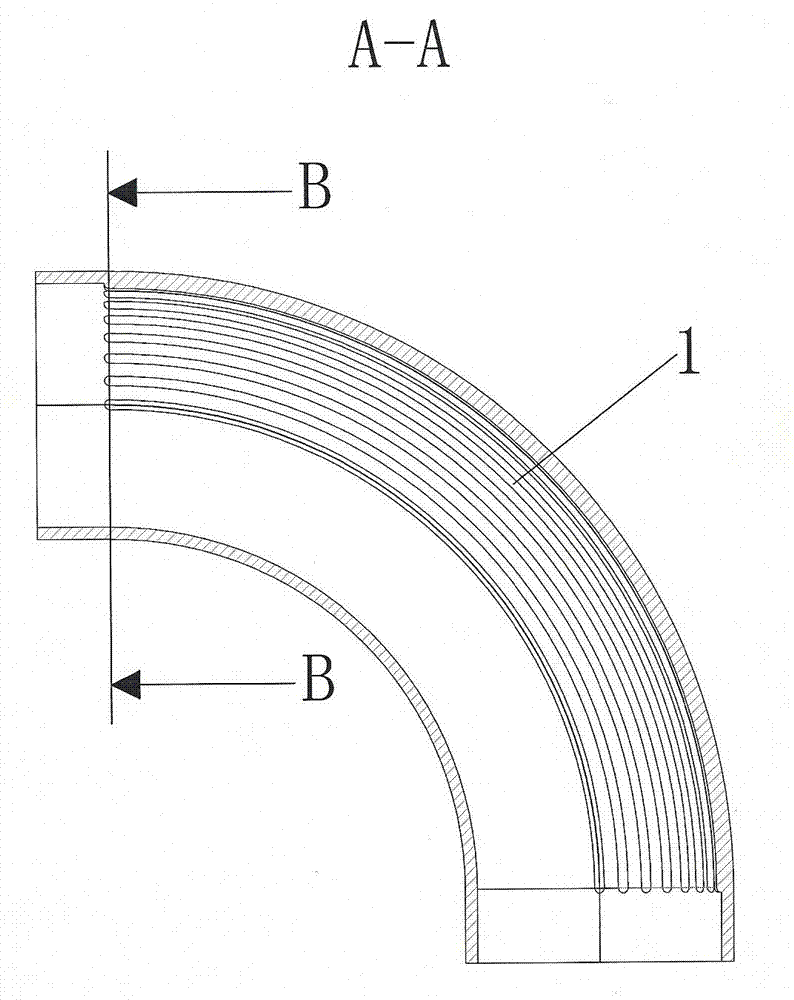

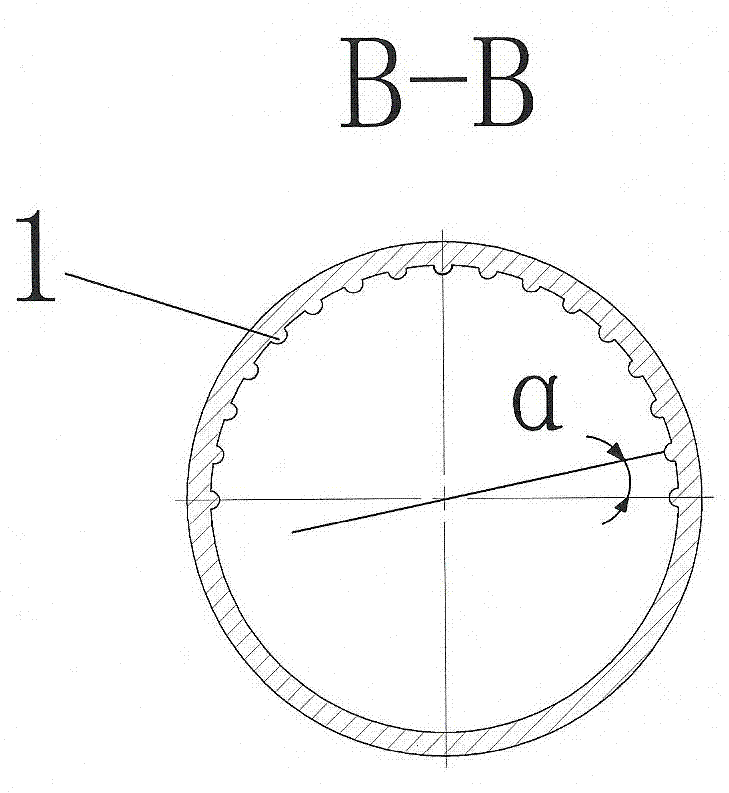

[0018] see Figure 1 to Figure 4 As shown, it is the first embodiment of the present invention. In this embodiment, the bionic ribs 1 are evenly arranged on the eroded surface of the pipe elbow, and the bionic ribs 1 are arranged along the flow direction in the span direction, and the bionic ribs 1 contact the curved surface of the flow field. The characteristic curve of the bionic rib is a section of inferior arc or semicircle. According to the difference of the Reynolds number of the continuous phase in the pipe elbow, the angle α between the two bionic ribs is 3-15°, the height h of the bionic rib is 0.2-4mm, and the section arc of the bionic rib The radius r is 0.2-5 mm.

[0019] In this embodiment, when the diameter of the pipeline is 100mm, the two-phase flow in the pipeline is oil and sand respectively, and the density of oil is 800kg / m 3 , when the viscosity is 0.048kg / m s, the speed is 6m / s, the average particle size of the sand is 0.55mm, and the flow rate is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com