Conducting wire icing on-line monitoring device and method based on OPGW (optical fiber composite overhead ground wire) optical fiber

A monitoring device and optical fiber technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of cumbersome installation, small monitoring range, and difficult power supply guarantee, so as to save installation work, less communication channel interference, and good detection The effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

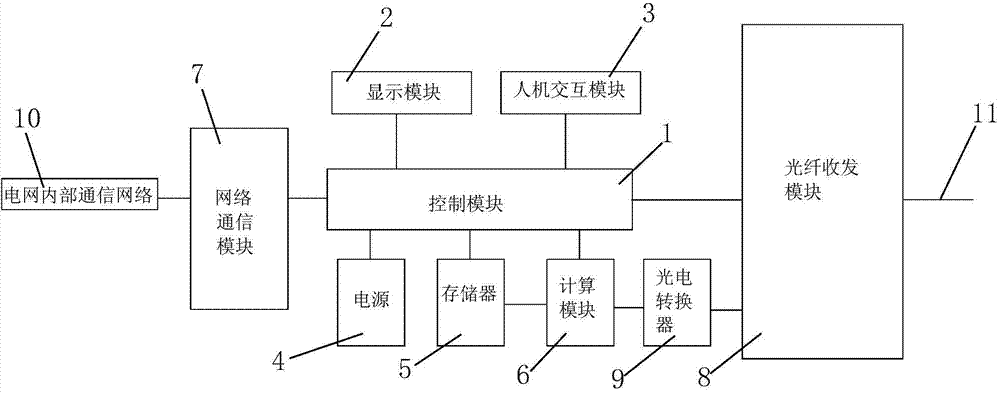

[0030] Such as figure 1 The shown online monitoring device for wire icing based on OPGW optical fiber includes a control module 1, a display module 2, a human-computer interaction module 3, a power supply 4, a memory 5, a computing module 6, a photoelectric converter 9, an optical communication terminal and a Measure the optical fiber transceiver module 8 connected to the OPGW optical fiber 11, wherein the control signal input end of the optical fiber transceiver module 8 is connected to the control module 1, and the optical feedback signal output end of the optical fiber transceiver module 8 is connected to the calculation module 6 through the photoelectric converter 9, and the calculation module 6 They are respectively connected to the memory 5 and the control module 1 , the display module 2 , the human-computer interaction module 3 and the me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com