Method for manufacturing solar tiles

A production method and solar energy technology, which can be applied to roofs using tiles/slate tiles, final product manufacturing, and renewable energy integration, etc., can solve problems that affect the appearance of buildings and related performance, so as to save installation work and be applicable Strong, protect the effect of the line

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A method for manufacturing a solar tile, the method comprising the following steps:

[0028] (1) Production of tile materials

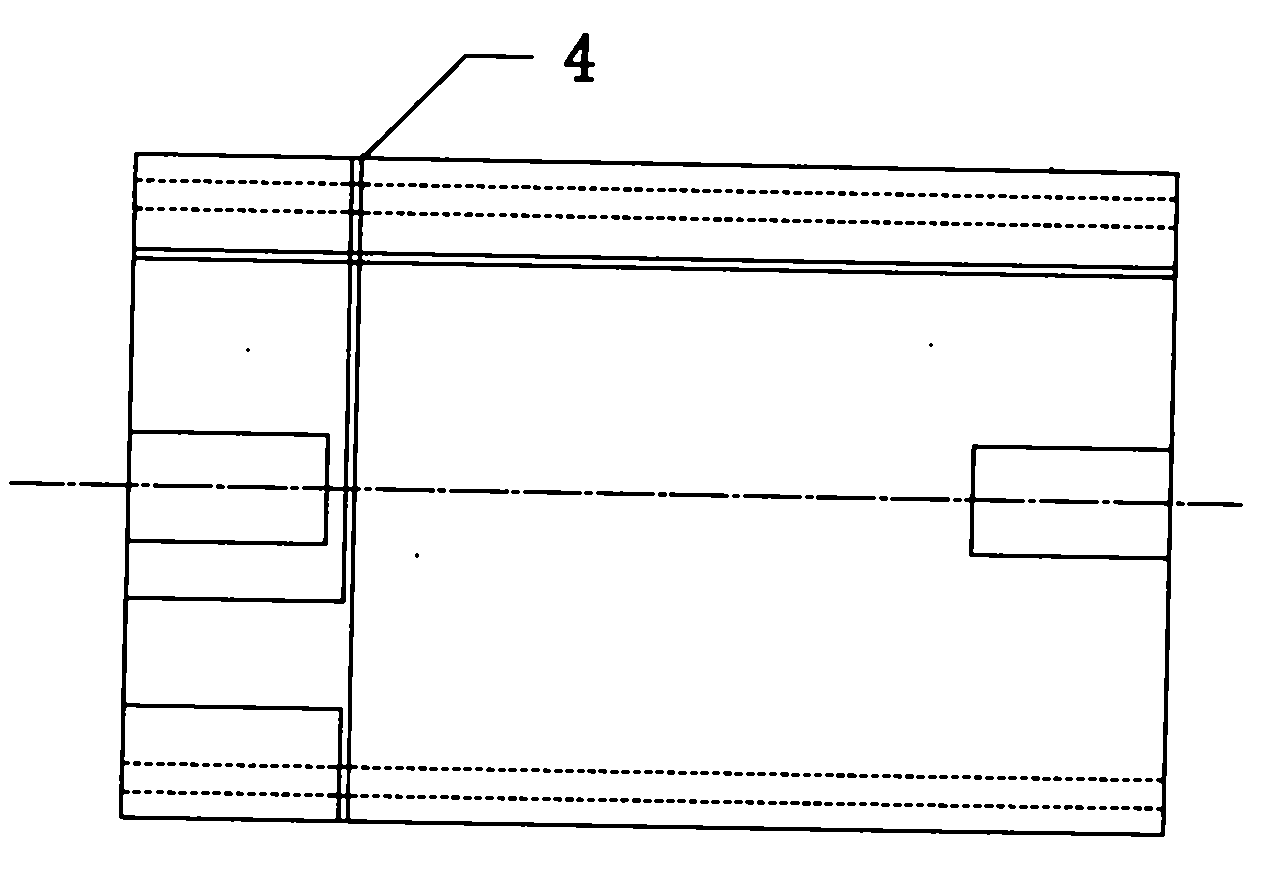

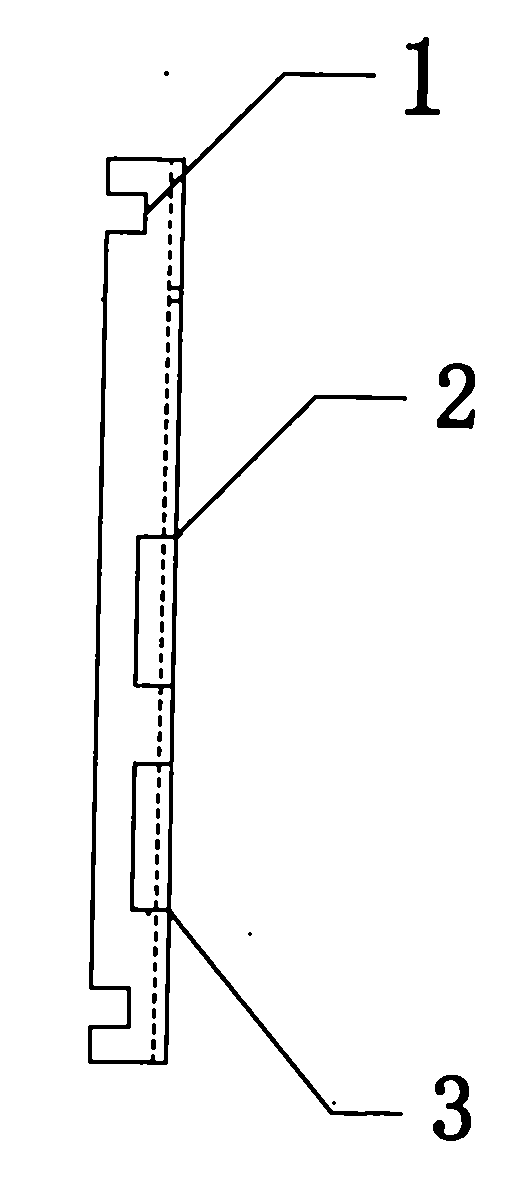

[0029] Such as Figure 1-4 As shown, the tile material A and the tile material B are prepared. There are some rectangular grooves on the upper and lower sides of the tile material A. The two ends of the upper surface of the tile material A are provided with splicing grooves 1. The splicing groove 1 is for the tiles. The lower surface is provided with positioning slot 2, which is designed for positioning the upper and lower tiles, the junction box slot 3 is designed for placing the junction box, and the circuit wire routing slot 4 is designed for circuit wire routing , tile B is provided with a connecting groove 5 matching the splicing groove on tile A, which is designed for splicing between tiles;

[0030] (2) Production of solar photovoltaic tiles

[0031] First, press Figure 5 Weld the battery as shown, and prepare ultra-clear tempered g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com