Digital sextant

A sextant, digital technology, applied in the field of digital sextant, can solve the problems of troublesome reading, difficult reading, troublesome, etc., and achieve the effect of automatic acquisition, automatic conversion and simple transmission.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

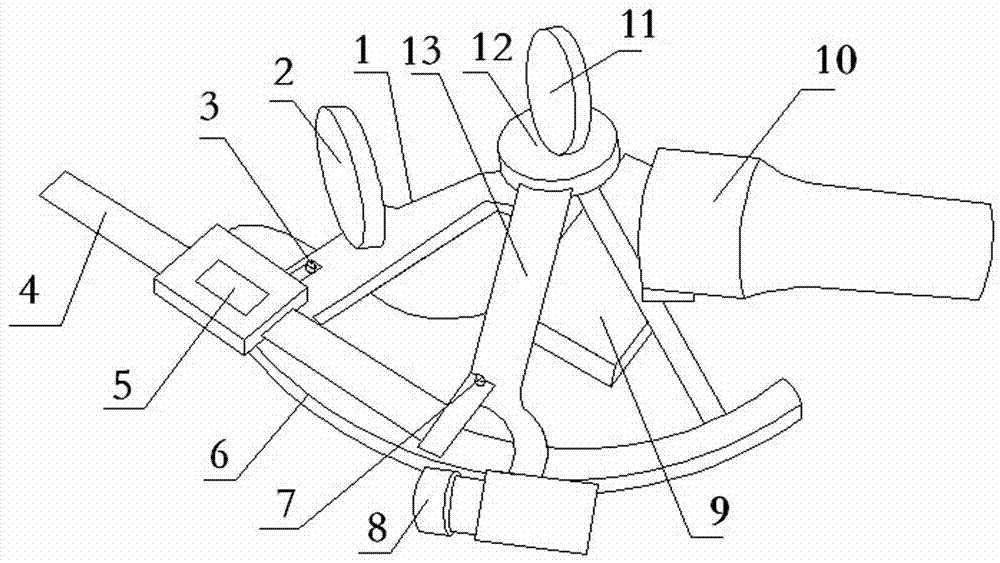

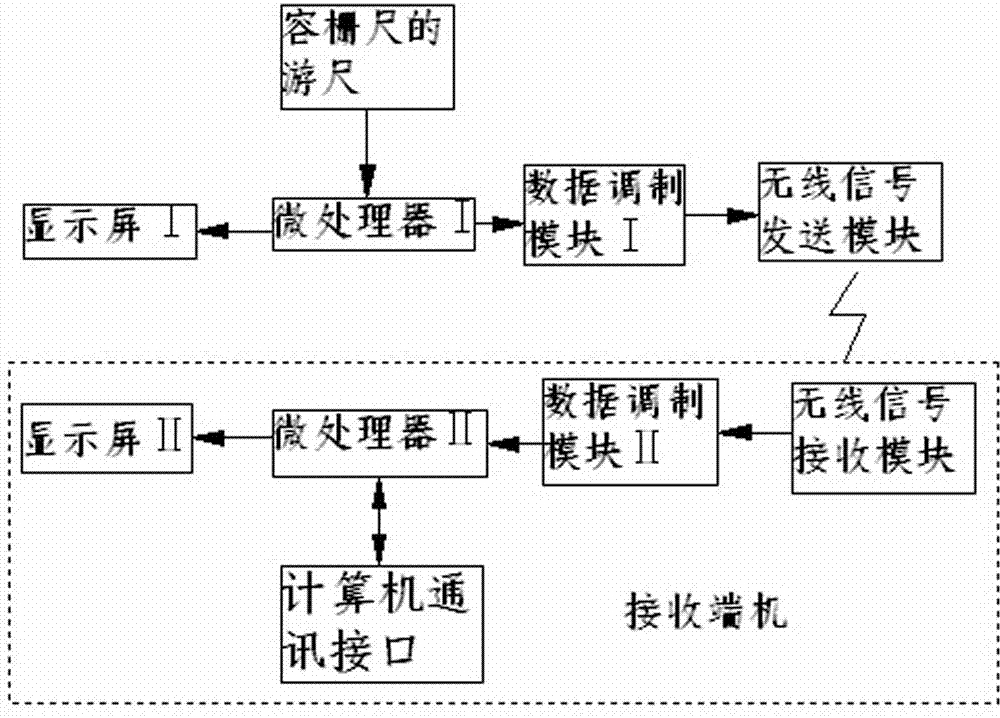

[0018] Such as figure 1 , 2 As shown, a digital sextant of the present invention is improved on the basis of the original mechanical sextant, realizes digitization, and measures more accurately.

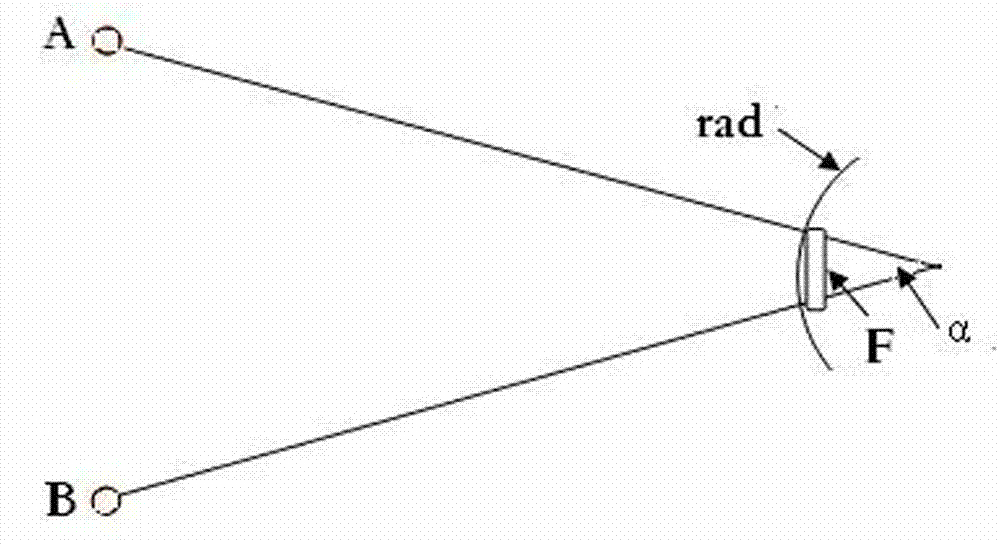

[0019] Specifically, comprise mechanical sextant, mechanical sextant comprises base 1, and base 1 is provided with fixed mirror 2, telescope 10, movable arm and arc index plate 6, and one end of movable arm 13 is provided with The moving mirror 11 is also connected to the angle between the base 1 and the index plate 6 through the rotating shaft I12. The capacitive scale is added, and the capacitive scale must be parallel to the base 1. One end of the body 4 of the capacitive scale is connected to the movable arm through the rotating shaft II7, and the vernier 5 of the capacitive scale is connected to the base 1 through the rotating shaft III3. The rotating shaft III3, the fixed mirror 2 and the rotating shaft I12 are on the same straight line, and the rotating shaft II7 The distan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com