Micro-vibration signal processing method

A signal processing and micro-vibration technology, which is applied to measuring devices, instruments, and measuring ultrasonic/sonic/infrasonic waves, etc., can solve unseen problems, reduce workload, reduce the accumulation of calibration errors, and facilitate use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

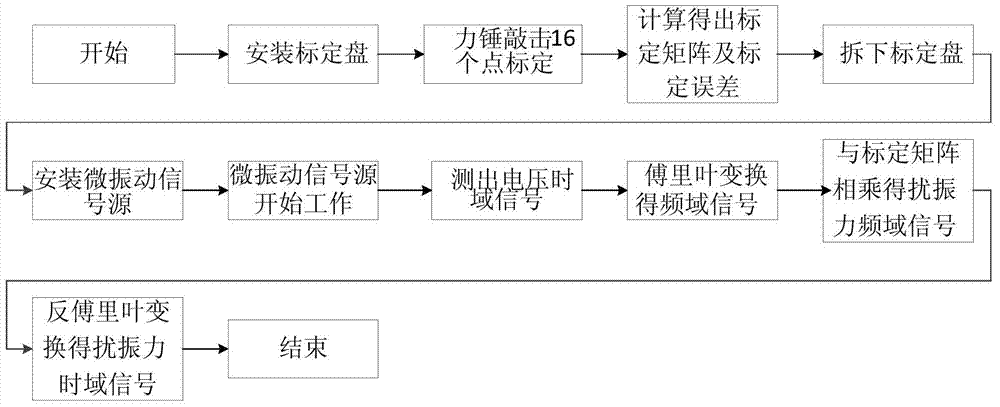

[0028] Such as image 3 As shown, the present invention provides a micro-vibration signal processing method, the voltage signal measurement is carried out on an eight-sensor six-component rigid force measuring platform, characterized in that the steps are as follows:

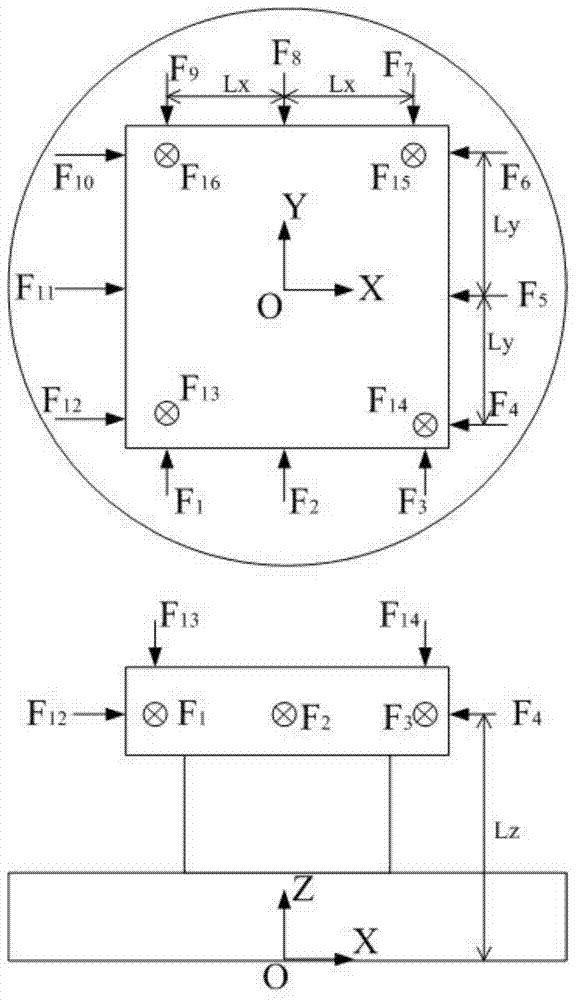

[0029] (1) Install the calibration plate on the eight-sensor six-component rigid force measuring platform, and tighten it with bolts; the calibration plate is a square aluminum plate, such as figure 1 As shown, there are 3 percussion points evenly distributed on the four sides of the calibration plate, 4 percussion points are distributed on the upper surface, and the lower surface is connected with the eight-sensor six-component rigid force measuring platform; the eight-sensor six-component rigid force measuring The platform is composed of eight unidirectional piezoelectric sensors, four of which are arranged along the horizontal direction to ensure that two disturbance forces along the horizontal direction and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com