Multifunctional testing loading detecting machine for horizontal sleeve compensator

A sleeve compensator and multi-functional testing technology, which is applied in the testing of machine/structural components, testing of mechanical components, and the use of stable tension/pressure to test the strength of materials, etc., which can solve inaccurate data and inaccurate detection parameters and other problems, to achieve the effect of large test space, space saving and convenient clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

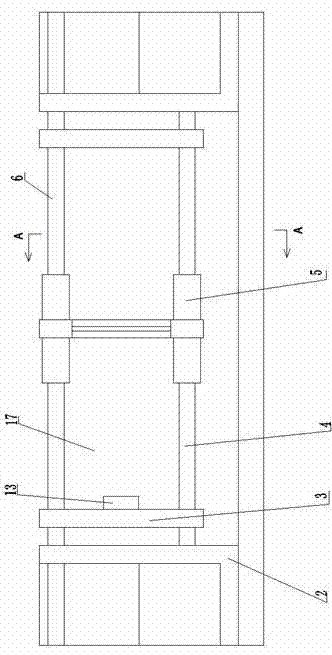

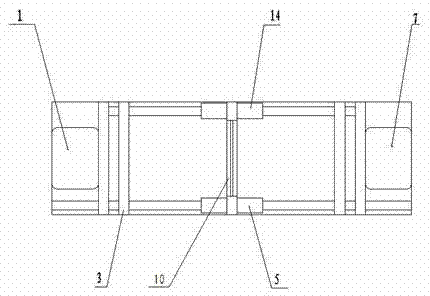

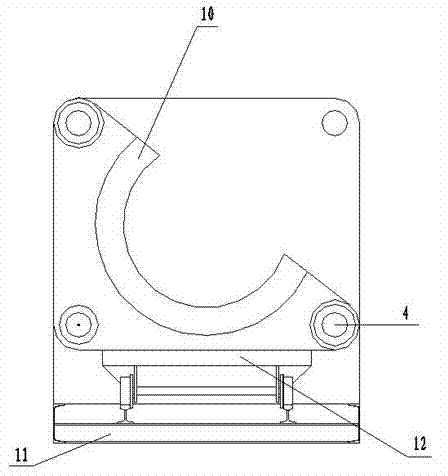

[0023] See Figure 1~5 , The test loading platform, hydraulic station, water pressure adjustment system, etc. are connected to the computer control system, and the computer control system is uniformly controlled and deployed. The hydraulic station 1 and the water pressure control device 7 are respectively fixed on both sides of the test loading platform; the test loading platform It includes a support 2, a guide post 4, an adjustable side sliding table 3, a movable cylinder-type balance cylinder 5 and a stress sensor 13. At least two guide posts are arranged between the two supports; two adjustable guide posts are arranged on the guide post Side sliding table, the guide post between the two adjustable side sliding tables is provided with a movable barrel type balancing oil cylinder, and the middle of the movable barrel type balancing oil cylinder is provided with a movable sliding table 10; at the center of one side of an adjustable side sliding table A stress sensor 13 is fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com