Device and method for measuring internal contact angle of high-temperature and high-pressure capillary tube

A high-temperature, high-pressure, measuring device technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve problems such as inability to meet test requirements, and achieve the effect of wide measurement range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

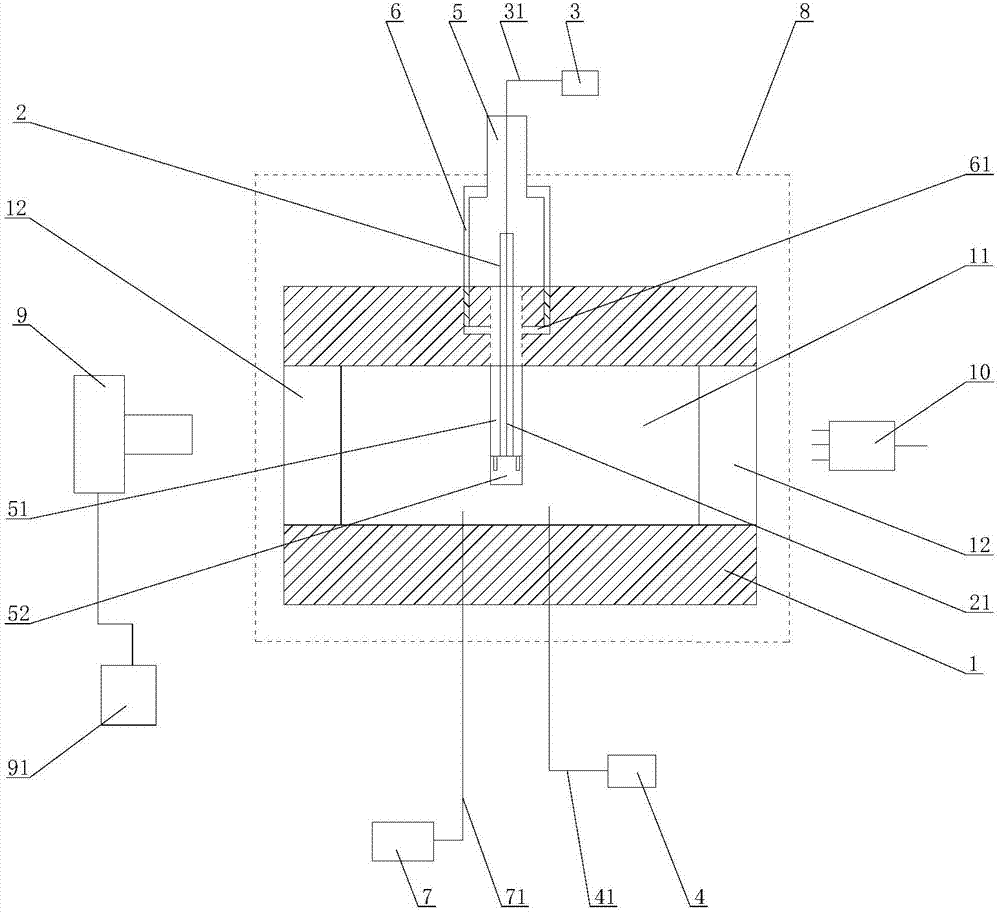

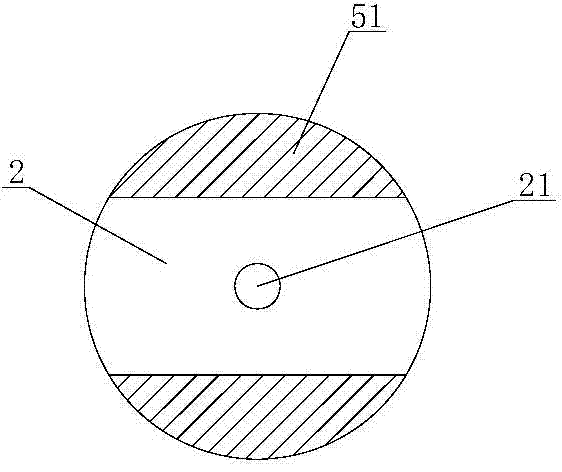

[0035] like figure 1 As shown, the present invention provides a high-temperature and high-pressure capillary internal contact angle measurement device, which includes a steel body 1 and a capillary 2 . Wherein: the steel body 1 has a through hole 11, and the two ends of the through hole 11 are respectively sealed with observation windows 12; one end of the capillary 2 is pierced in the through hole 11 of the steel body 1, and the other end is injected through the first fluid. The pipeline 31 is connected to a first fluid injection pump 3 ; the second fluid injection pump 4 is connected to a second fluid injection pipeline 41 , and the second fluid injection pipeline 41 extends into the through hole 11 of the steel body 1 .

[0036] Specifically, the steel body 1 is generally cylindrical, with a through hole 11 opened in the middle, and a transparent observation window 12 is respectively provided at both ends of the steel body 1, and the observation window 12 is used to allow t...

Embodiment approach 2

[0048] like Figure 1-2 As shown, the present invention provides a method for measuring the internal contact angle of a high-temperature and high-pressure capillary tube. The high-temperature and high-pressure capillary internal contact angle measuring method adopts the above-mentioned high-temperature and high-pressure capillary internal contact angle measuring device. The structure, working principle and beneficial effects are the same as those of Embodiment 1, and will not be repeated here. The high temperature and high pressure capillary internal contact angle measurement method comprises the steps:

[0049] a) Fill fluid into the first fluid injection pump 3, and fill gas into the second fluid injection pump 4;

[0050] b) Inject the fluid into a capillary 2 through the first fluid injection pump 3, and the capillary 2 extends into a through hole 11 of a steel body 1, and the two ends of the through hole 11 are respectively sealed with observation windows 12. Inject the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com