Auto-dimming spectacles and manufacturing method thereof

A manufacturing method and anti-glare technology, applied in glasses/goggles, optics, instruments, etc., can solve the problems of easy to produce dizziness, fixed discoloration intensity, wavelength insensitivity, etc., to achieve improved visual experience, long service life, and safety. high sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

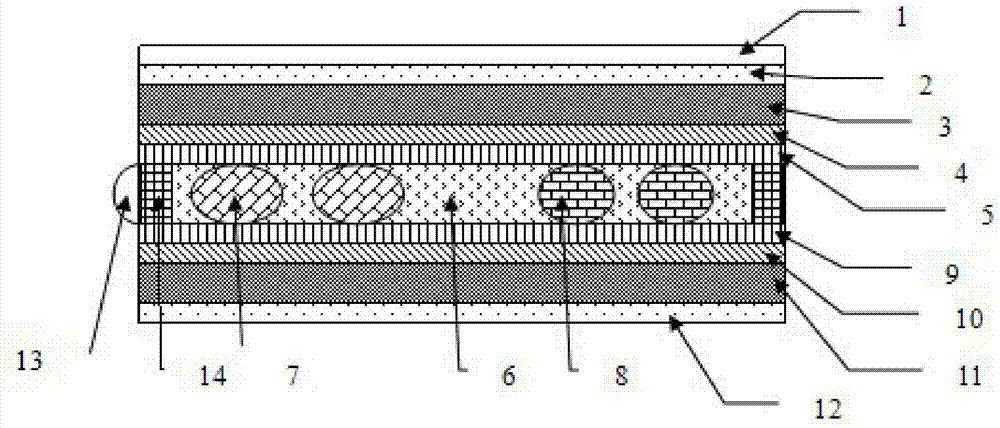

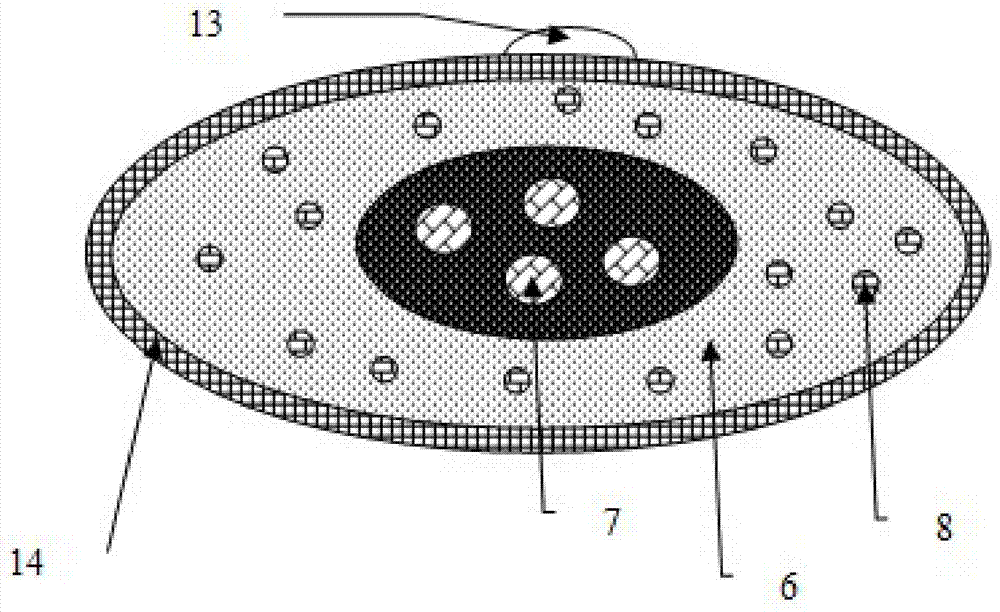

[0037] A type of automatic anti-glare glasses (such as figure 1 shown), the sequence from the front surface to the glasses consists of photochromic layer 1, UV protection layer I2, substrate I3, transparent electrode layer I4 attached to the substrate I3, vertical alignment film I5, dye liquid crystal layer 6, vertical Alignment film II9, transparent electrode layer II10, substrate II11 and UV protection layer II12 are superimposed; two kinds of spacer materials (such as figure 2 shown), are the spacer material I7 and the spacer material II8 respectively, the planes of the substrate I3 and the substrate II11 are matched with the patterns on the transparent electrode layer I4 and the transparent electrode layer II10, and the substrate I3, the substrate II11 and the seal 13 and sealing ring 14 arranged around the dye liquid crystal layer 6 form a liquid crystal cell. Wherein, the photochromic layer 1 is selected from the organic photochromic material hexaarylbiimidazole; the v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com