Industrial explosive warehouse optimal management operating system and goods optimal management method

An industrial explosive and operating system technology, applied in logistics, data processing applications, electromagnetic radiation induction, etc., to achieve the effects of improving use efficiency, optimizing distribution, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

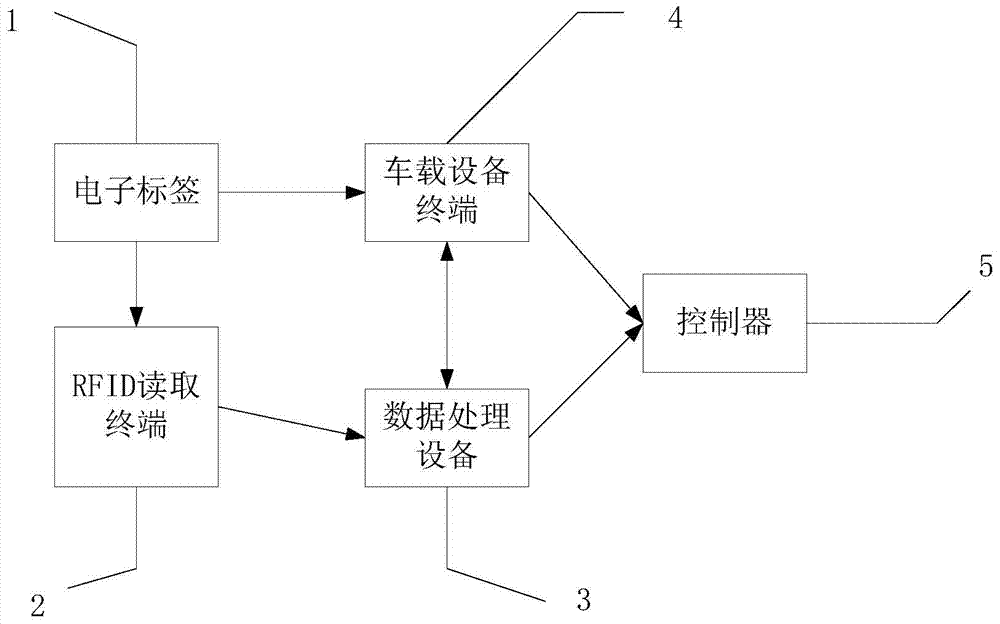

[0055] Such as figure 1 As shown, it is a structure diagram of a specific embodiment of an industrial explosive warehouse optimization management operating system in the present invention. see figure 1, the industrial explosive warehouse optimization management operating system of this embodiment includes an electronic tag 1, an RFID reading terminal 2, a data processing device 3, a vehicle-mounted terminal device 4, and a controller 5:

[0056] Electronic label 1, which is set on the goods and on each location of the warehouse;

[0057] The RFID reading terminal 2 is connected with the data processing device 3, and is used to read the information on the electronic tag and transmit it to the data processing device 3;

[0058] The vehicle-mounted terminal device 4 is connected with the data processing device 3 and the controller 5, and is used to read the information on the electronic tag and transmit it to the data processing device 3 and receive the operation information se...

Embodiment 2

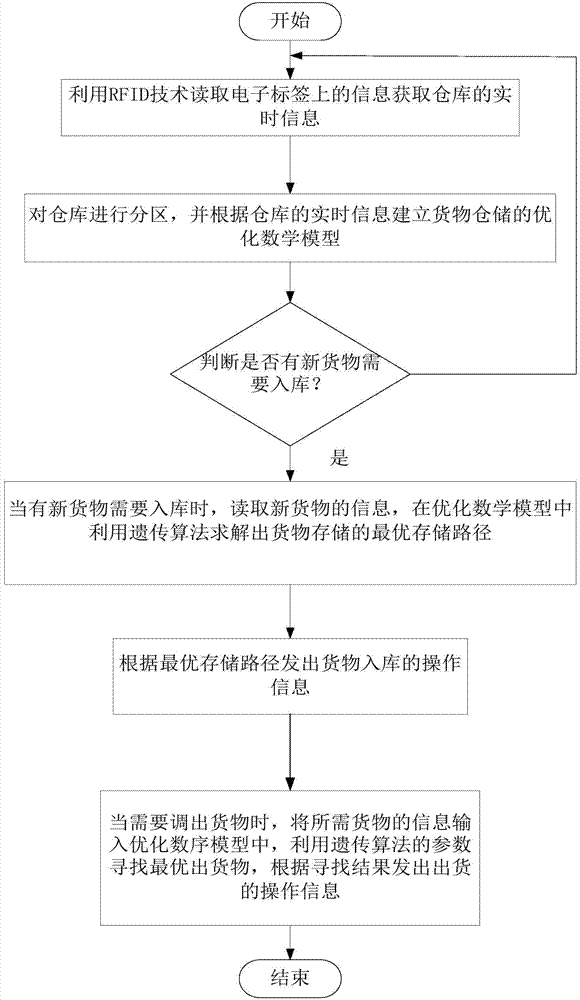

[0068] Such as figure 2 As shown, it is a flow chart of a specific embodiment of the cargo optimization management method of the optimized management operating system of the industrial explosives warehouse in the present invention, wherein, this specific embodiment adopts the optimized management operation of the industrial explosives warehouse described in Embodiment 1 System implementation. see figure 2 , the specific steps of the cargo optimization management method of the optimization management operating system of the industrial explosives warehouse of the present embodiment include:

[0069] S101: Utilize RFID technology to read the information on the electronic tag to obtain real-time information of the warehouse;

[0070] S102: partitioning the warehouse, and establishing an optimized mathematical model for cargo storage according to the real-time information of the warehouse;

[0071] S103: When new goods need to be stored, read the information of the new goods, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com