Water pump pressure switch

A water pump pressure and switch technology, which is applied in the field of water pump control switch improvement, can solve the problems of affecting spring size, expensive manufacturing cost, pressure error, etc., and achieve the effect of stable operation, high precision and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

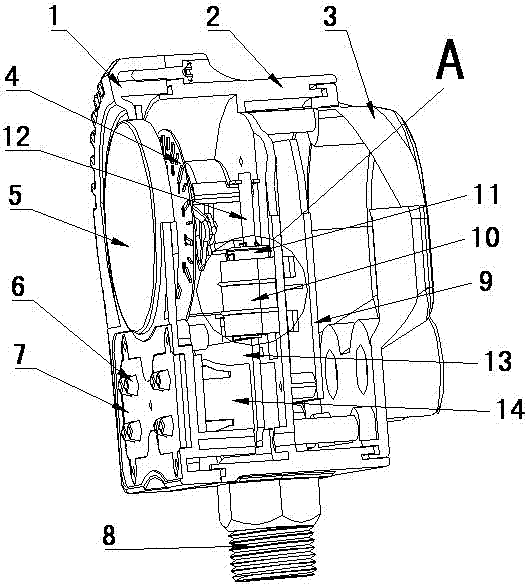

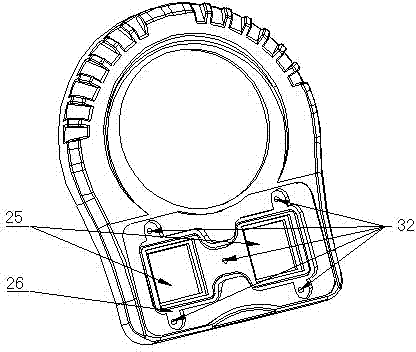

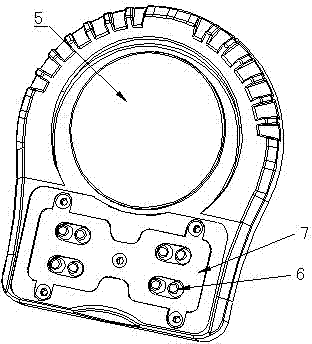

[0036] attached Figure 1-13 The water pump pressure switch according to the present invention includes a sealed housing; the sealed housing includes a middle body 2; a hollow metal threaded joint 8 extending outward is connected directly below the sealed housing, and the metal The threaded joint 8 is connected with the threaded hole 29 below the middle body 2 through the thread 30 at its end. The sealed housing includes a panel 1, a middle body 2, a lower cover 3, and a transparent window 5, wherein the transparent window 5 is connected to the panel. 1. It is connected as a whole by ultrasonic welding technology. There are two square through holes 25 on the panel 1. The square through holes 25 are used to install two dial switches 14. At the same time, the H-shaped groove 26 on the panel 1 is It is used to install the transparent ru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com