Shaft-driven wire outlet overhead trolley

A technology of shaft transmission and flying car, applied in the direction of overhead line/cable equipment, etc., can solve the problems of poor reliability of the outgoing car, loose chain, falling off the chain, etc., to achieve good riding stability, reduce the number, and improve the effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

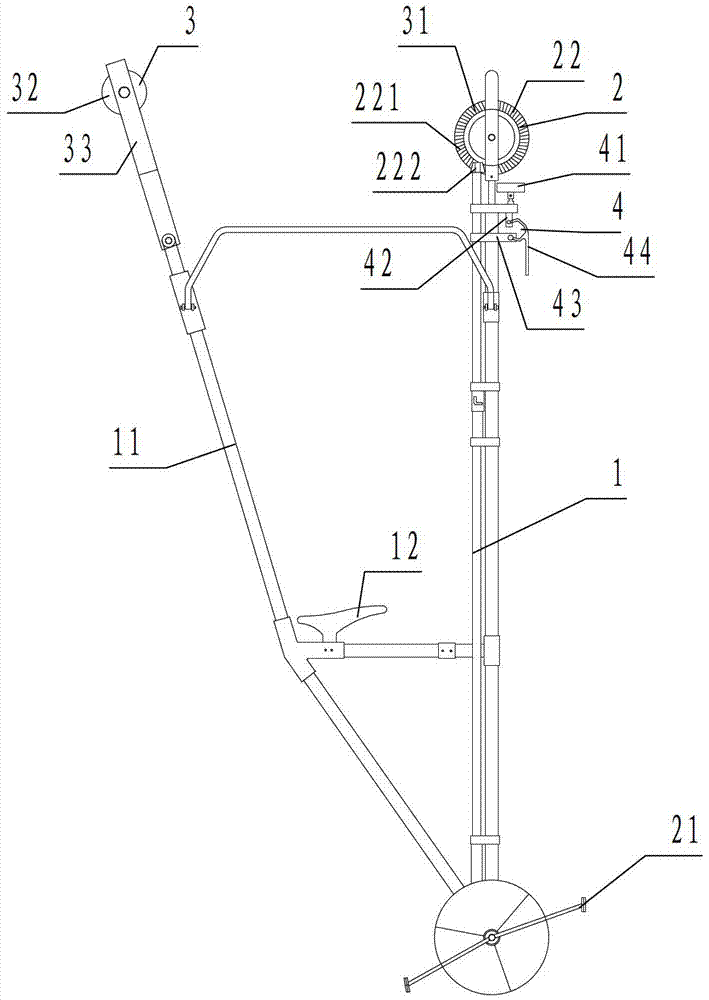

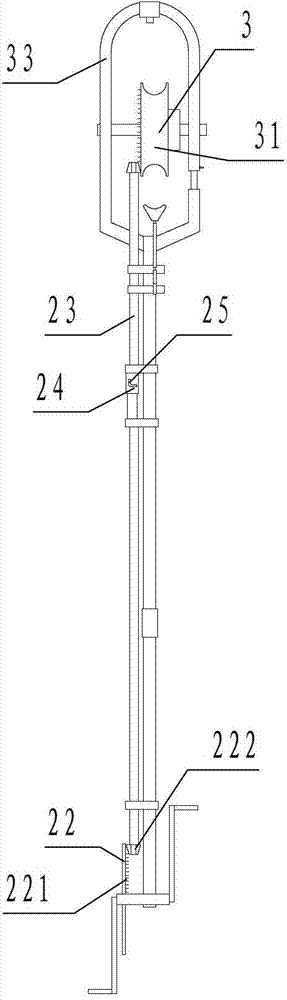

[0023] a kind of like Figure 1-2 The shown shaft drive outgoing line flying car includes a car body 1, a transmission device 2, a running device 3, and a braking device 4. The car body includes a vehicle frame 11 and a seat 12 installed on the vehicle frame. The device includes a driving wheel 31 and a driven wheel 32, the driving wheel and the driven wheel are respectively arranged on the traveling wheel bracket 33 at the upper end of the vehicle frame, and the traveling wheel bracket is provided with an open slot that can be inserted into the wire. The transmission device includes pedal 21, upper and lower gear sets 22, transmission shaft 23 and clutch 24, and described upper gear set includes large sector gear 221 and small sector gear 222, and described large sector gear and driving wheel Coaxial or integrated structure, the transmission shaft is composed of upper and lower transmission shafts, and the upper and lower transmission shafts are connected by a clutch. The clu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com