Patents

Literature

59results about How to "Safe and reliable transmission" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

On-line monitoring device for high-voltage circuit breaker

InactiveCN103869239AImprove reliabilityComprehensive online monitoringCircuit interrupters testingElectromagnetic interferenceEngineering

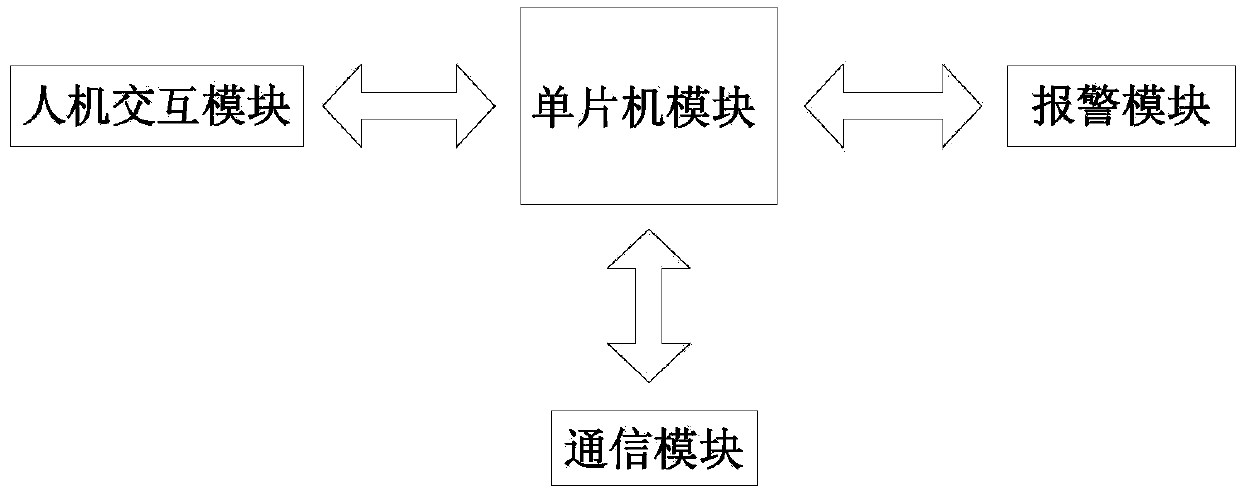

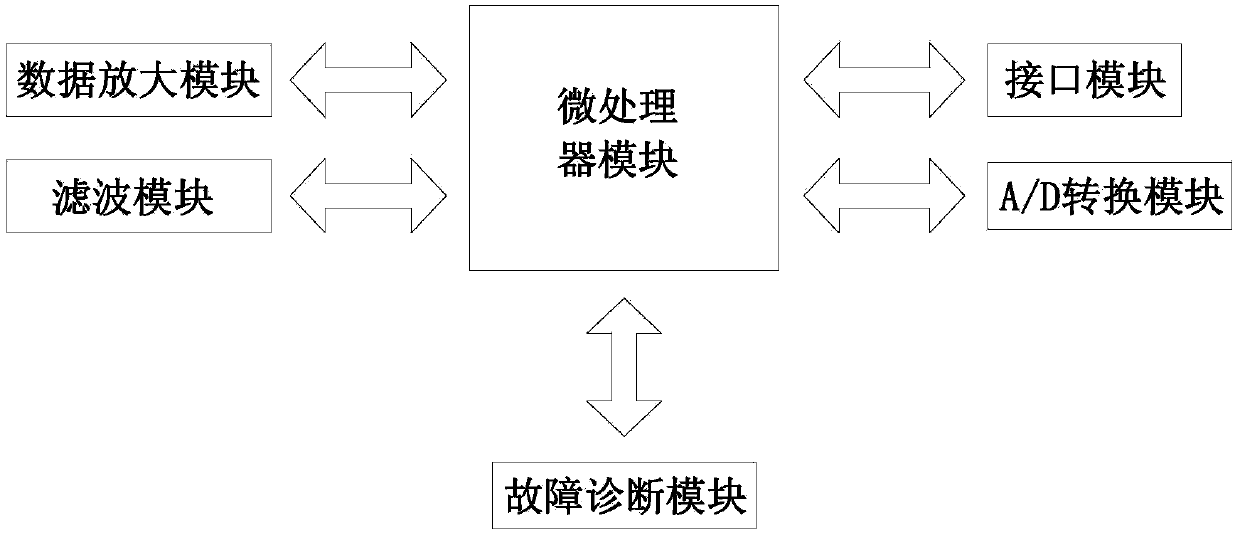

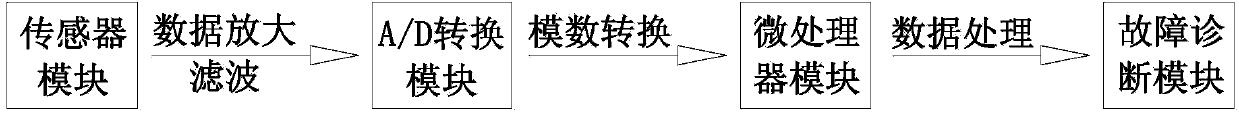

The invention provides an on-line monitoring device for a high-voltage circuit breaker. The on-line monitoring device comprises a sensor module and an on-line high-voltage circuit breaker monitoring unit, wherein the on-line high-voltage circuit breaker monitoring unit comprises a single-chip microcomputer module, a communication module, a human-machine interaction module and an alarming module; the single-chip microcomputer module is a functional module and is integrated with a data amplification module, a filtering module, an A / D (analog / digital) conversion module, a micro processor module, a fault diagnosis module and an interface module. The on-line monitoring device for the high-voltage circuit breaker performs real-time monitoring according to switch on and switch off current of the circuit breaker and state information such as a travel mechanical characteristic of a main contact, so that the definite state information can be supplied in real time, and local digitalization, remote networking and monitoring and prewarning automation are realized; therefore the reliability of running of the circuit breaker is improved. The device can comprehensively, scientifically and accurately monitor a real-time running state of the high-voltage circuit breaker on line, effectively avoid strong electromagnetic interference and completely and safely send data to a monitoring terminal.

Owner:TIANJIN ZHOUYU ELECTROMECHANICAL EQUIP SCI & TECH

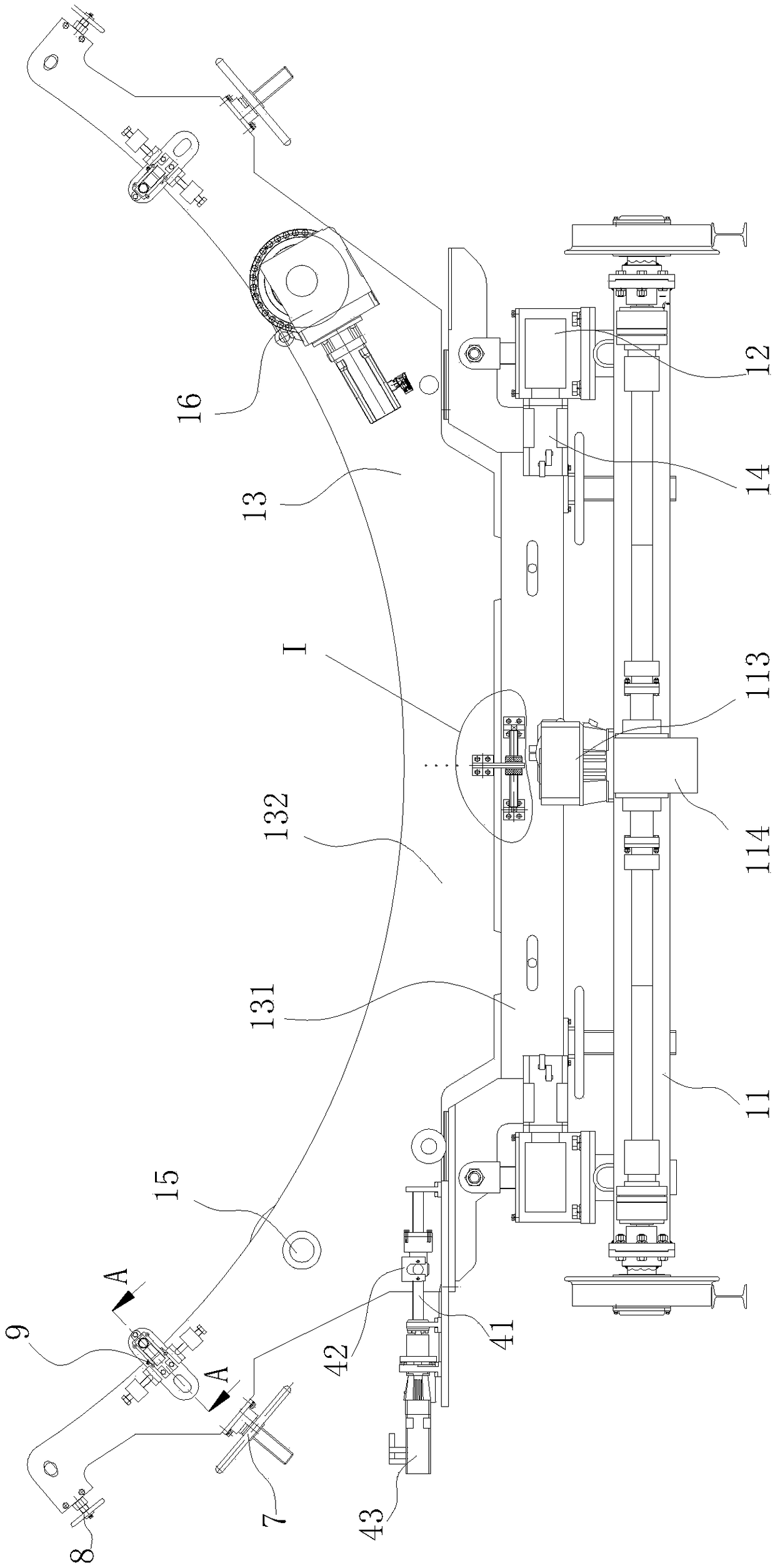

Method for automatically detecting air valve friction welding yield strength

InactiveCN106769473AHigh degree of automationImprove work efficiencyMaterial strength using tensile/compressive forcesConveyor partsCantilevered beamEngineering

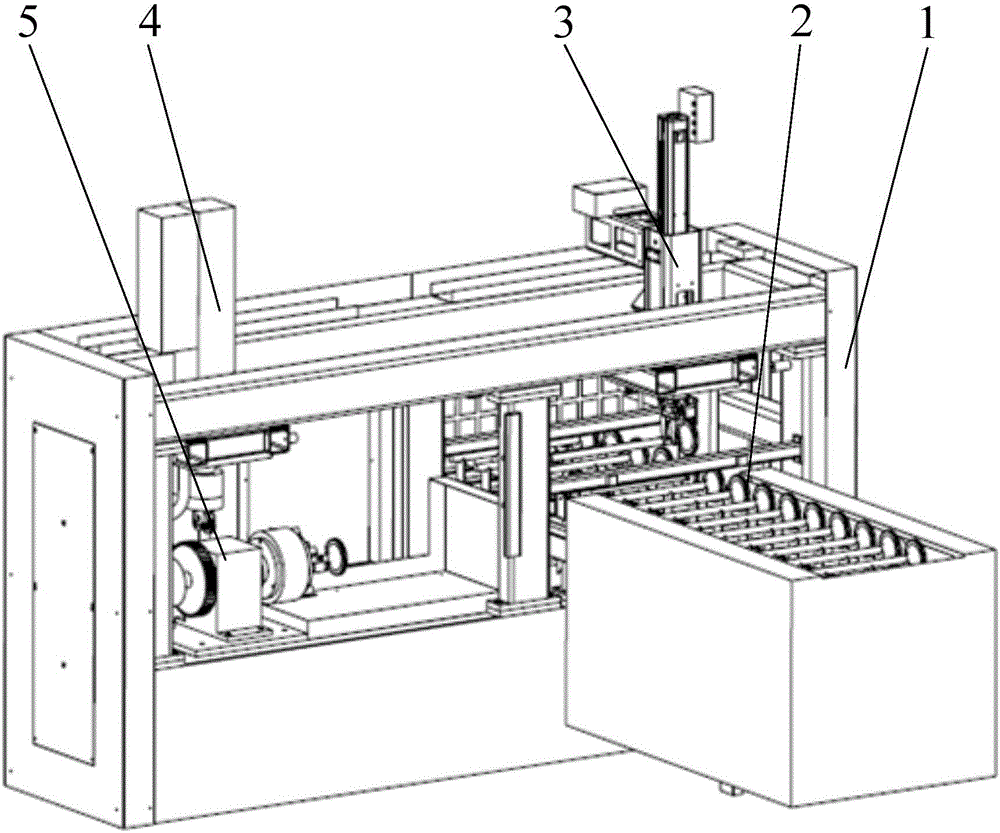

The present invention discloses a method for automatically detecting the air valve friction welding yield strength. The method comprises following steps: 1, tightly clamping the rod part of an air valve to be detected by a clamping finger at the front end of a hydraulic clamping plate, wherein the head of the air valve froms a cantilever beam structure at the outside; 2, driving the hydraulic clamping plate to rotate by a fourth driving mechanism, and driving a pressing plate to move to a position right above the head of the air valve by a third driving mechanism; 3, driving the pressing plate to move downwards by a servo electric cylinder, applying a down-pressing load onto the head of the air valve, detecting the down-pressing displacement of the servo electric cylinder by a grating ruler in real time, detecting output pressure of the servo electric cylinder by a pressure sensor, after the air valve deforms to a pre-set deformation amount under the down-pressing load, stopping the action of the servo electric cylinder, keeping the pressure for a time period t, and then unloading; and 4, detecting whether the air valve is yielded to be ruptured by an optoelectronic switch for material interrupting detection. The method has the advantages of high detection precision, high universality and high degree of automation.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

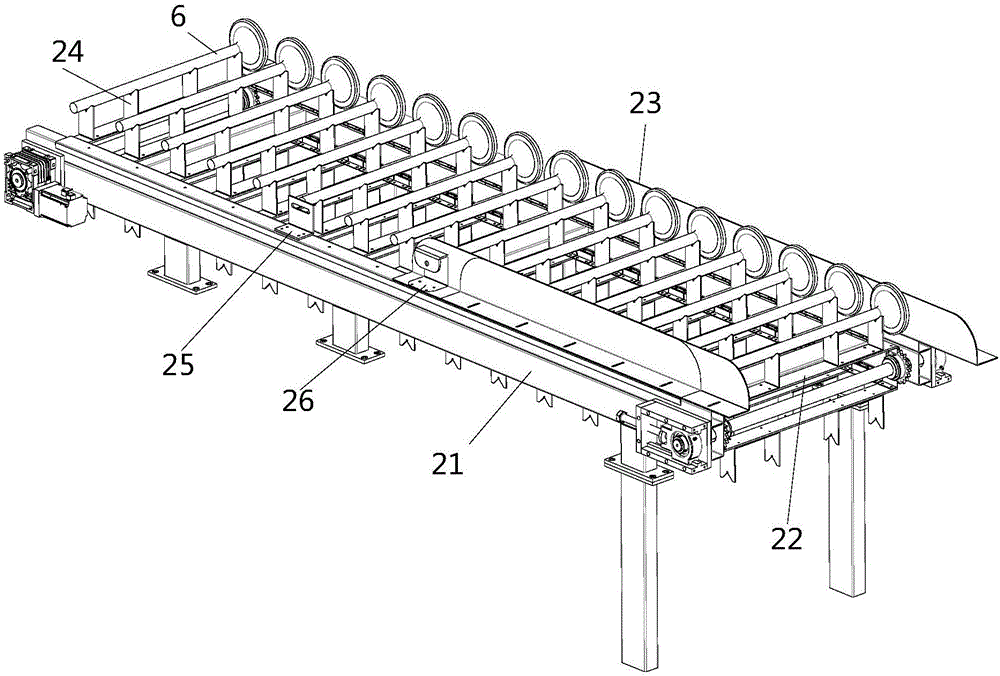

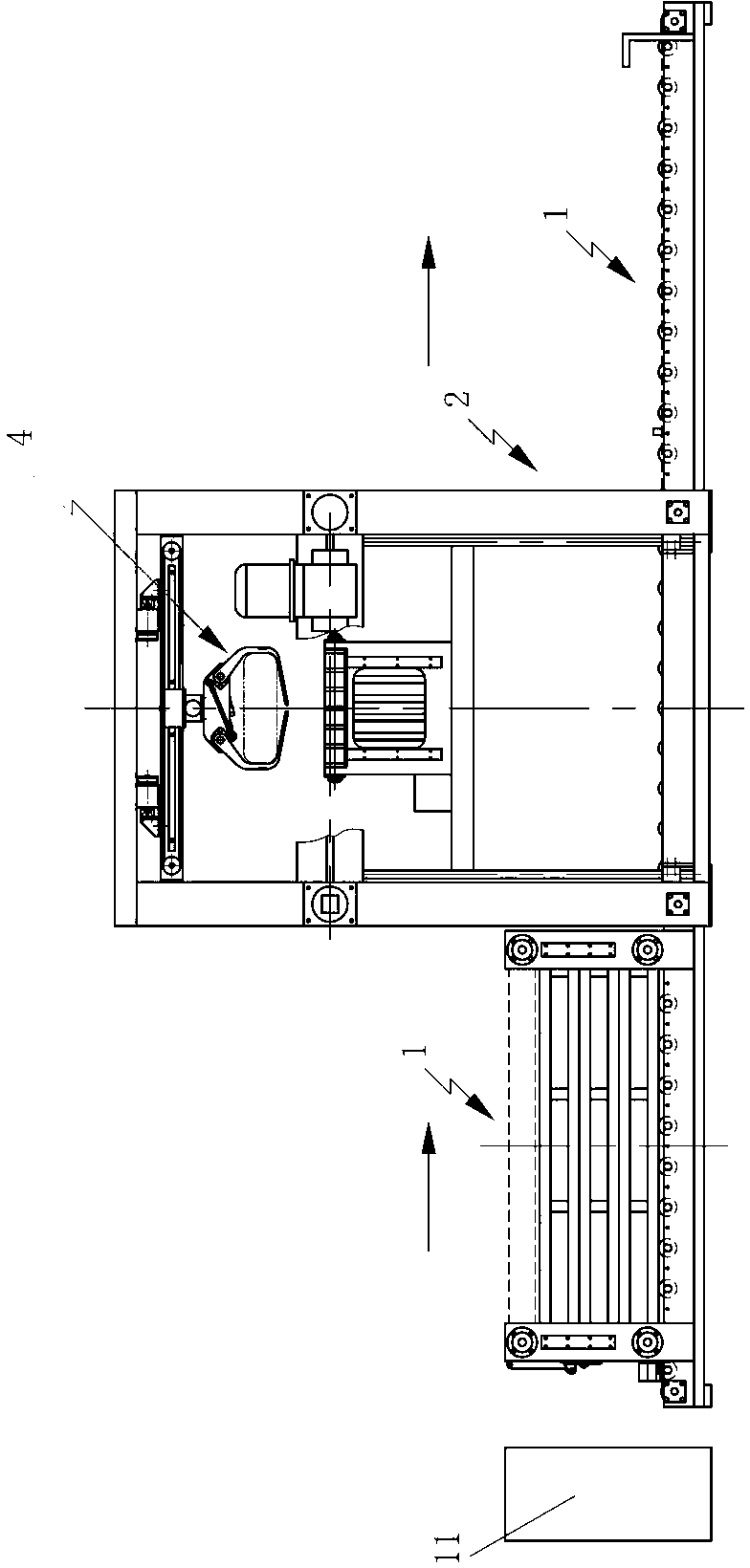

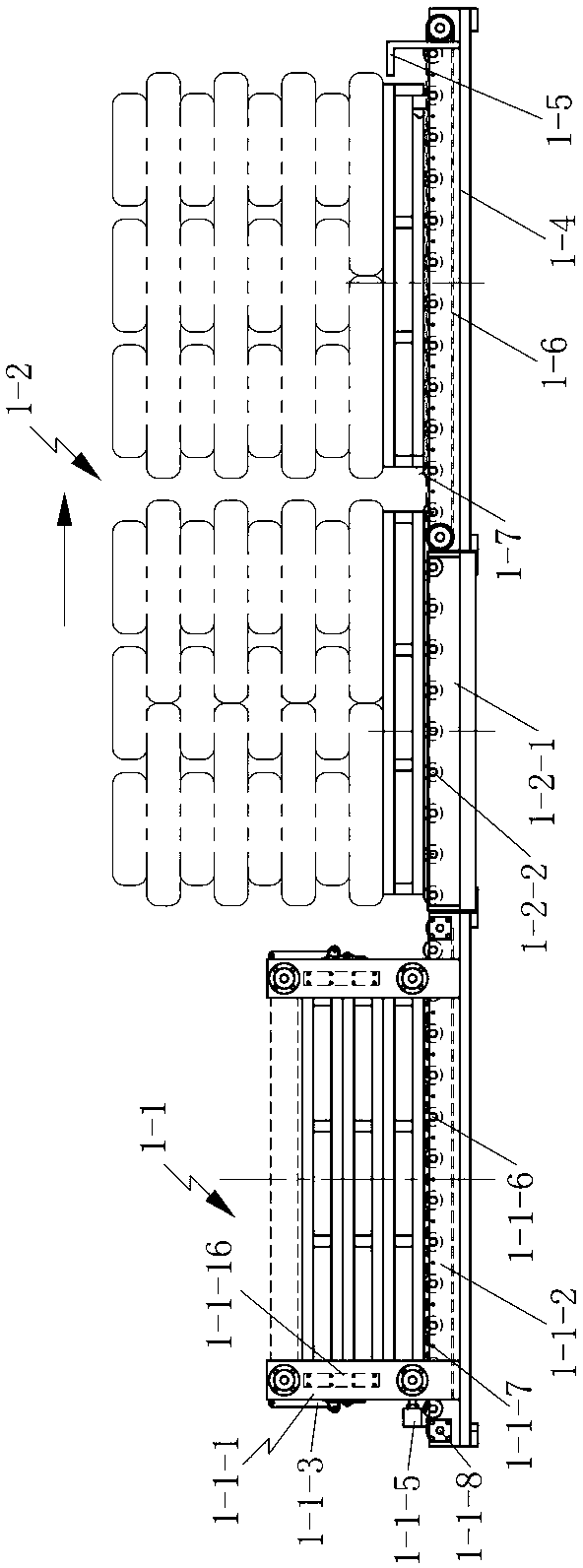

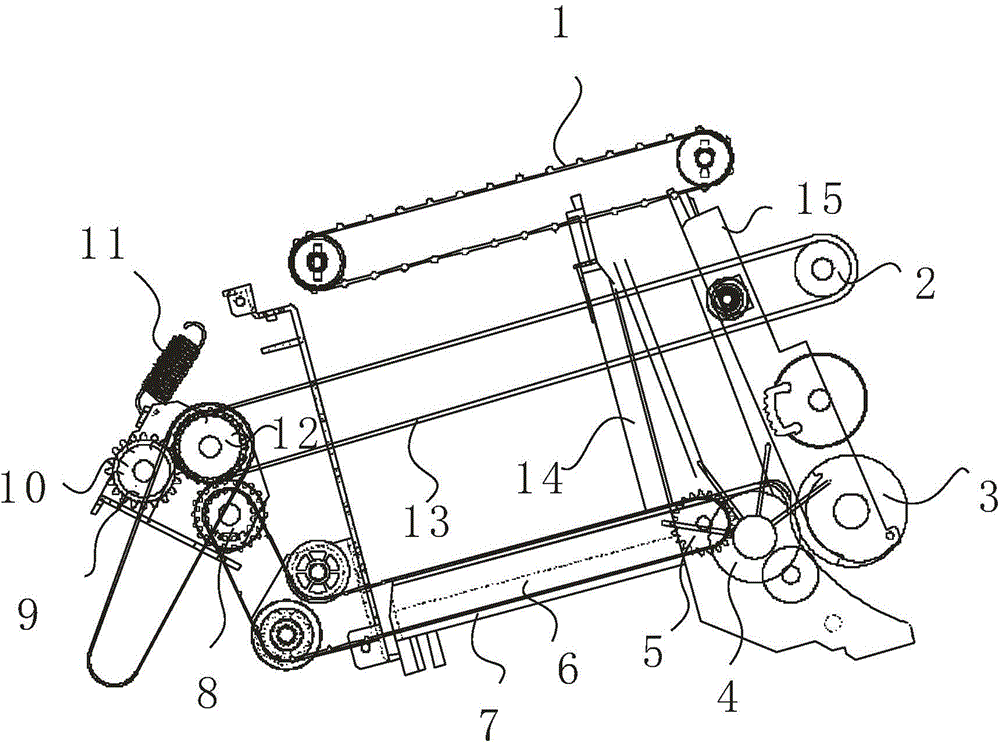

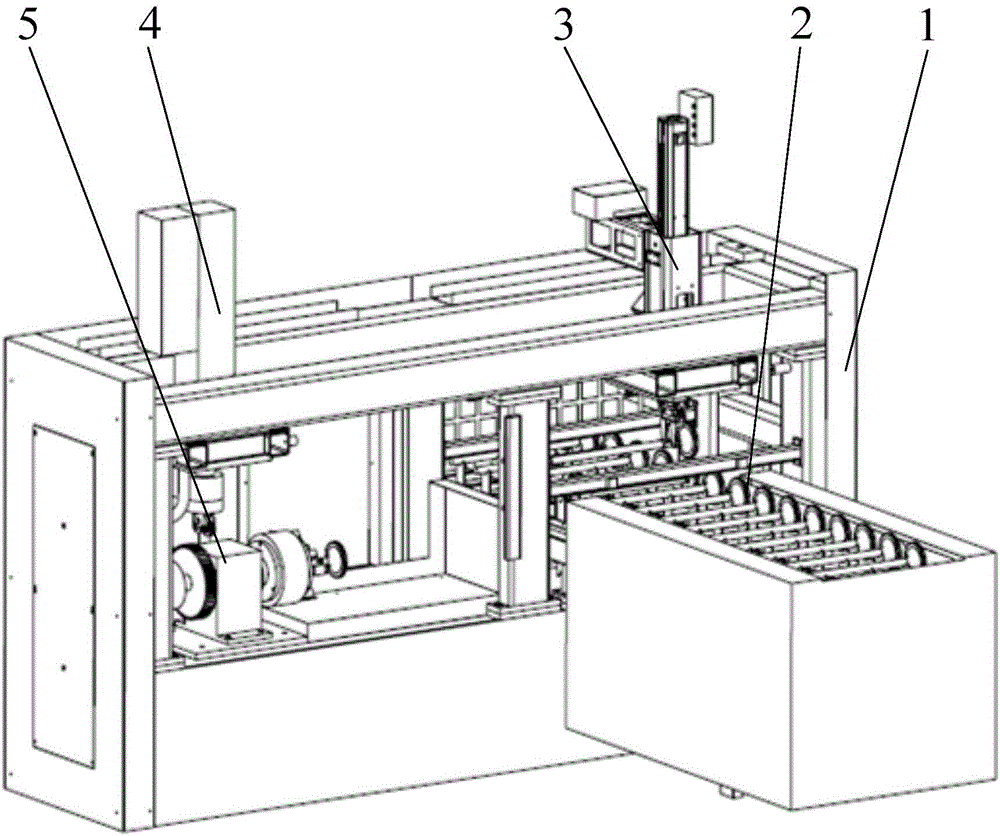

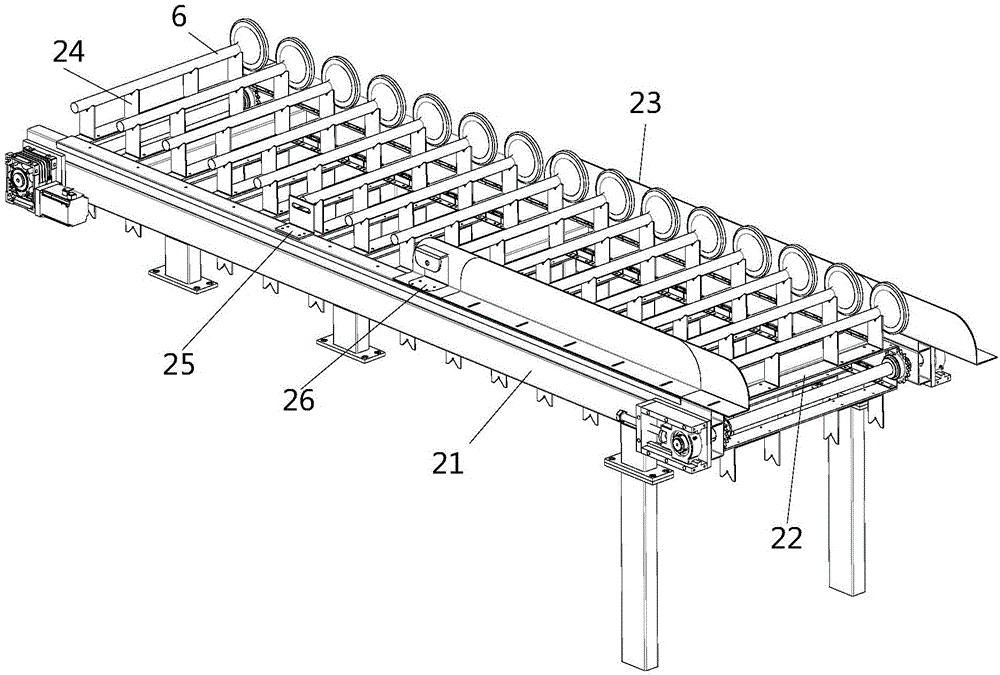

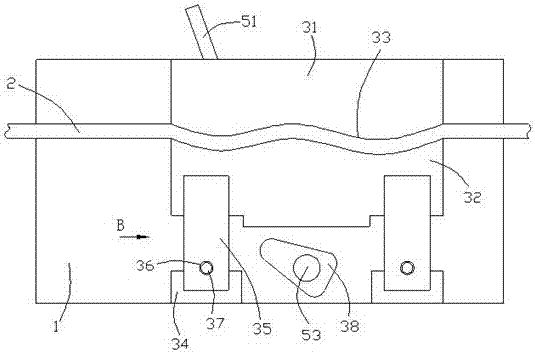

Stacking transmission system

InactiveCN102887372ASuitable for continuous automatic productionSave manpower and material resourcesConveyorsStacking articlesMaterial resourcesManipulator

The invention relates to a stacking transmission system which comprises stacking device and a tray lifting, propelling and conveying device, wherein the tray lifting, propelling and conveying device consists of a tray feeding device and an output stack conveying device; the stacking device is located between the tray feeding device and the output stack conveying device; the tray feeding device comprises a rack, a conveying frame, a lifting mechanism, a lifting beam and a push rod; the stacking device comprises a stacking rack with four struts, a vertical transmission motor and a longitudinal transmission motor; a tray is glidingly matched on the stacking rack along the vertical direction of the struts; a longitudinal beam is glidingly matched at the top of the stacking rack; a transverse sliding block is in transmission connection to the longitudinal beam through a transverse motor and a transverse tooth-shaped belt; and a manipulator is fixed on the transverse sliding block. According to the transmission connection through the tooth-shaped belt, the transmission stability is good and the structure is simple. The stacking transmission system provided by the invention is simple in structure, stable in action, capable of continuously completing the stacking of bagged articles in automatic production, so as to save the manpower and the material resources and have high stacking efficiency.

Owner:溧阳市正申饲料机械厂

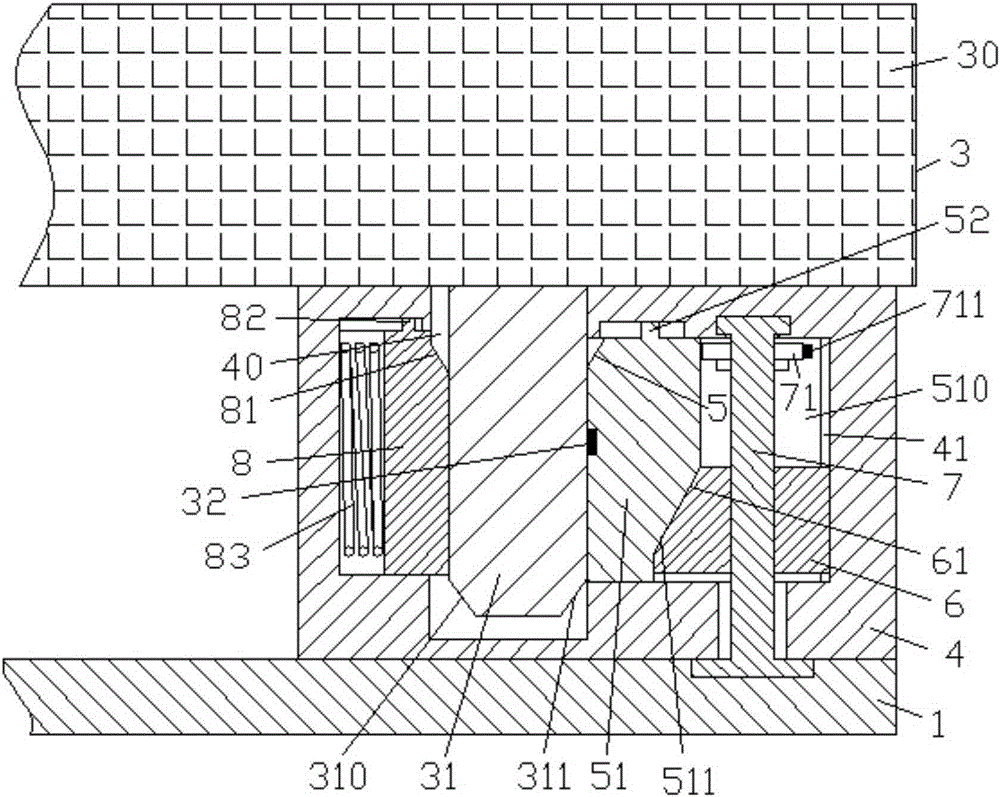

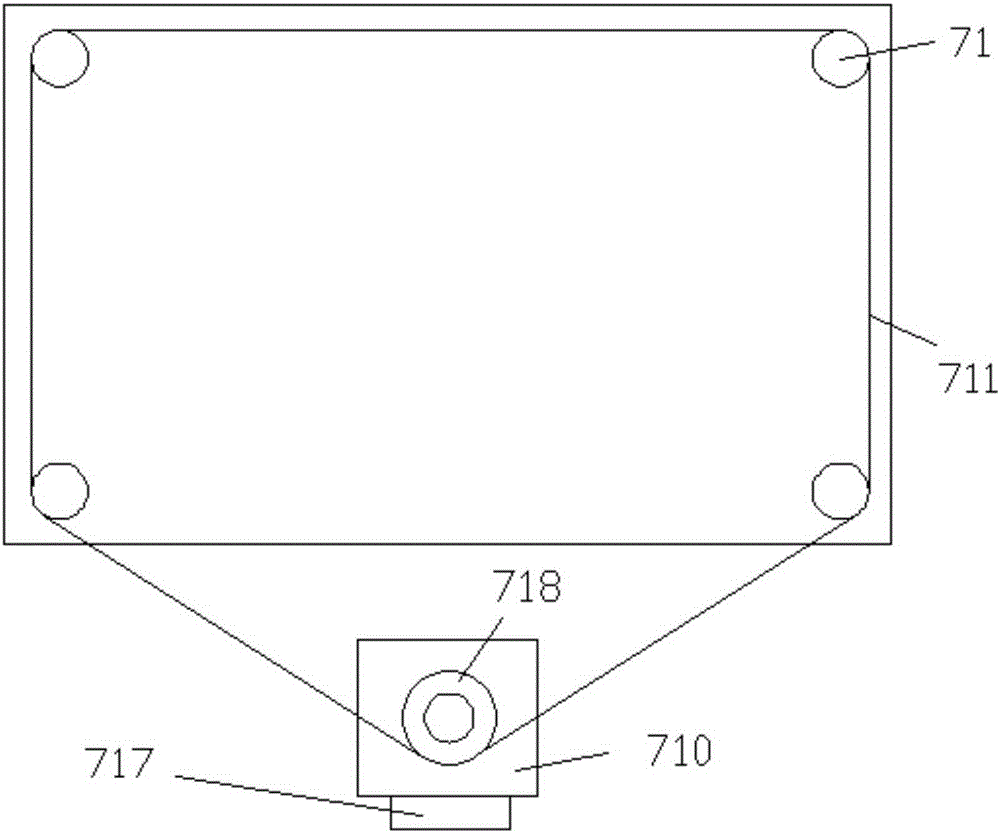

Circuit board assembly driven by chain and provided with locking indicator lamp

InactiveCN105240359AAvoid mounting fixesRealize the installation and fixationSheet joiningEngineeringElectrical and Electronics engineering

The invention discloses a circuit board assembly driven by a chain and provided with a locking indicator lamp. The circuit board assembly comprises a circuit board device (3) and a base fixing device. The circuit board device (3) comprises a rectangular body part (30) and four fixed feet (31) located at the corners of the rectangle respectively. The base fixing device comprises a base (1) and four mounting frames (4) which are fixed to the base (1) and correspond to the four fixed feet (31) respectively. Inserting grooves (40) allowing the fixed feet (31) to be inserted are formed in the mounting frames (4), and inside clamping blocks (8) which are biased by the jacking and pressing springs (83) and can stretch into the inserting grooves (40) are arranged at the inner sides, close to the inner side of the body part (30) of the circuit board device (3), of the inserting grooves (40) of the mounting frames (4).

Owner:肖锐

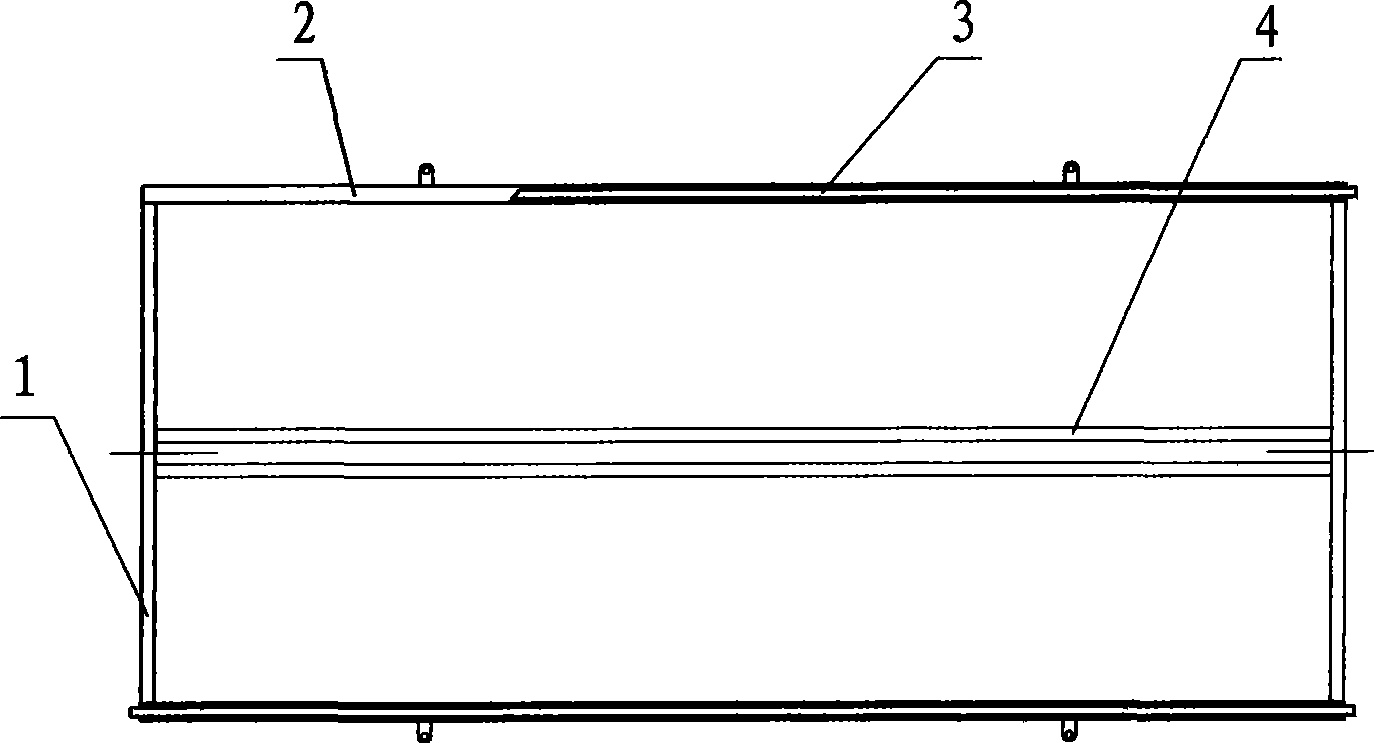

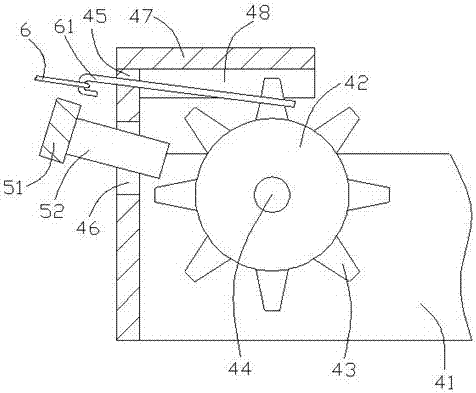

Large-capacity bill storage device for financial self-service terminal

InactiveCN105139511ALarge capacityReasonable transmissionCoin/currency accepting devicesDrive wheelTransmission belt

The present invention relates to a device for a financial self-service terminal and particularly relates to a large-capacity bill storage device for a financial self-service terminal. The device comprises a bill storage and withdrawal warehouse formed by a bill guidance plate, an elastic limit belt, a bill pushing plate and a bill support frame. The bill storage and withdrawal warehouse is inclined to the direction of the bill pushing plate. The lower end of the bill guidance plate is provided with a friction wheel. The bill pushing plate moves back and forth through a transmission belt which is fixedly connected to the bill pushing plate. One end of the transmission belt sleeves a tension driven wheel, and the other end sleeves a power output wheel. The power output wheel drives a bill synchronous belt to move through transmission gear transmission. The front end of the bill synchronous belt drives a bill push wheel. The upper plane of the bill synchronous belt is arranged above the bill support frame. The teeth of the bill thumbwheel are raised from a bill support frame plane. The front end of the bill support frame is provided with push leaves. Both a power output wheel bearing and a transmission gear bearing are fixedly connected to a sheet metal bracket. One end of the sheet metal bracket is fixedly connected to a stretched spring, the capacity of the bill storage and withdrawal warehouse is effectively increased, and the overall transmission is reasonable and safe.

Owner:CASHWAY FINTECH CO LTD

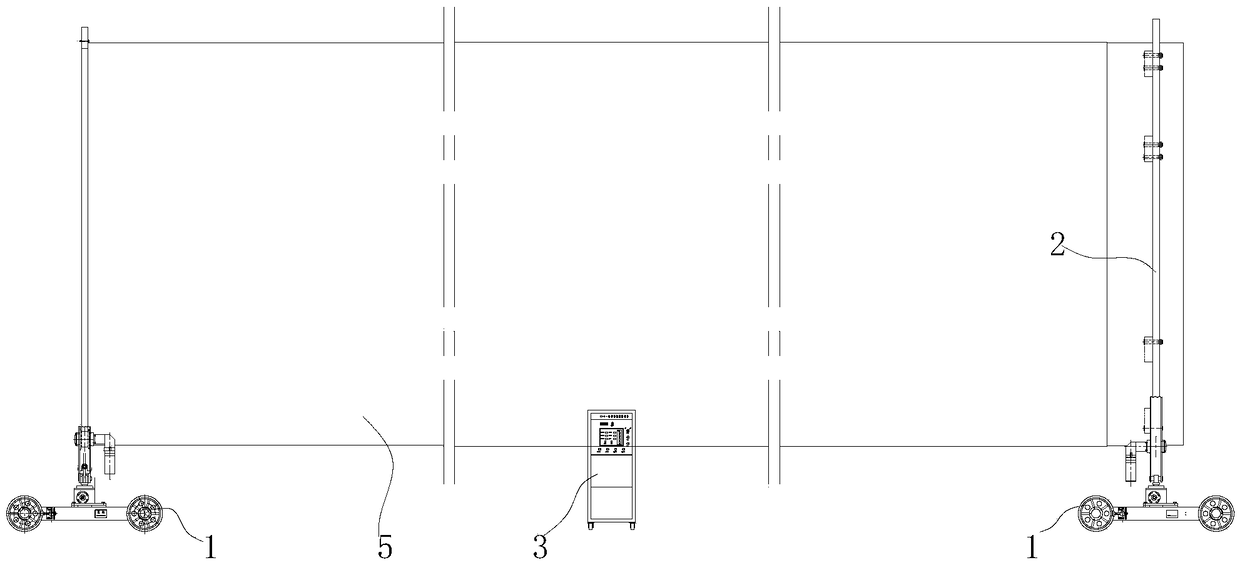

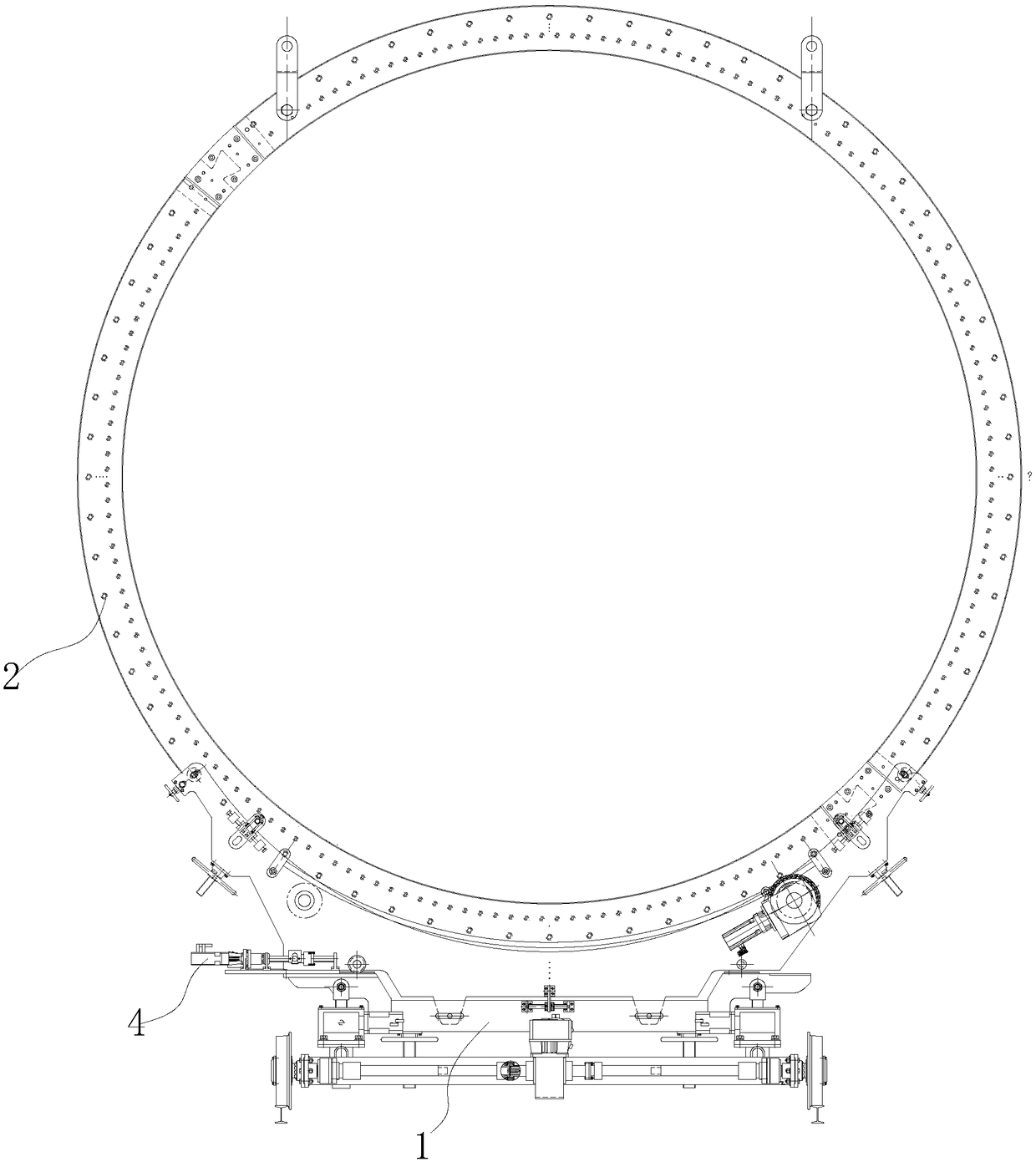

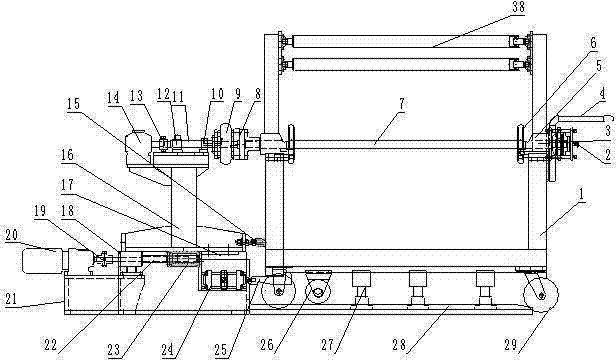

Space rocket body rolling apparatus

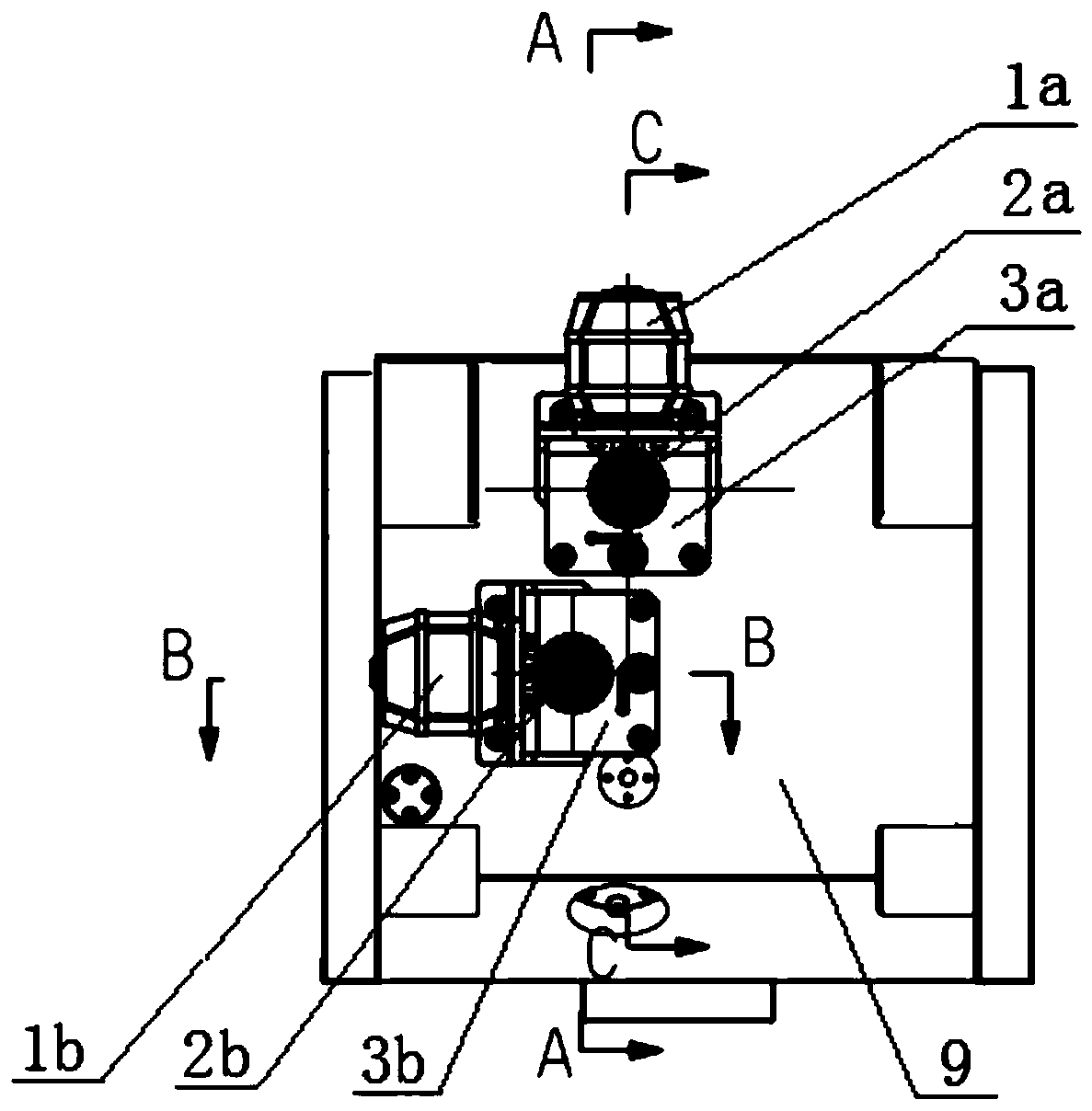

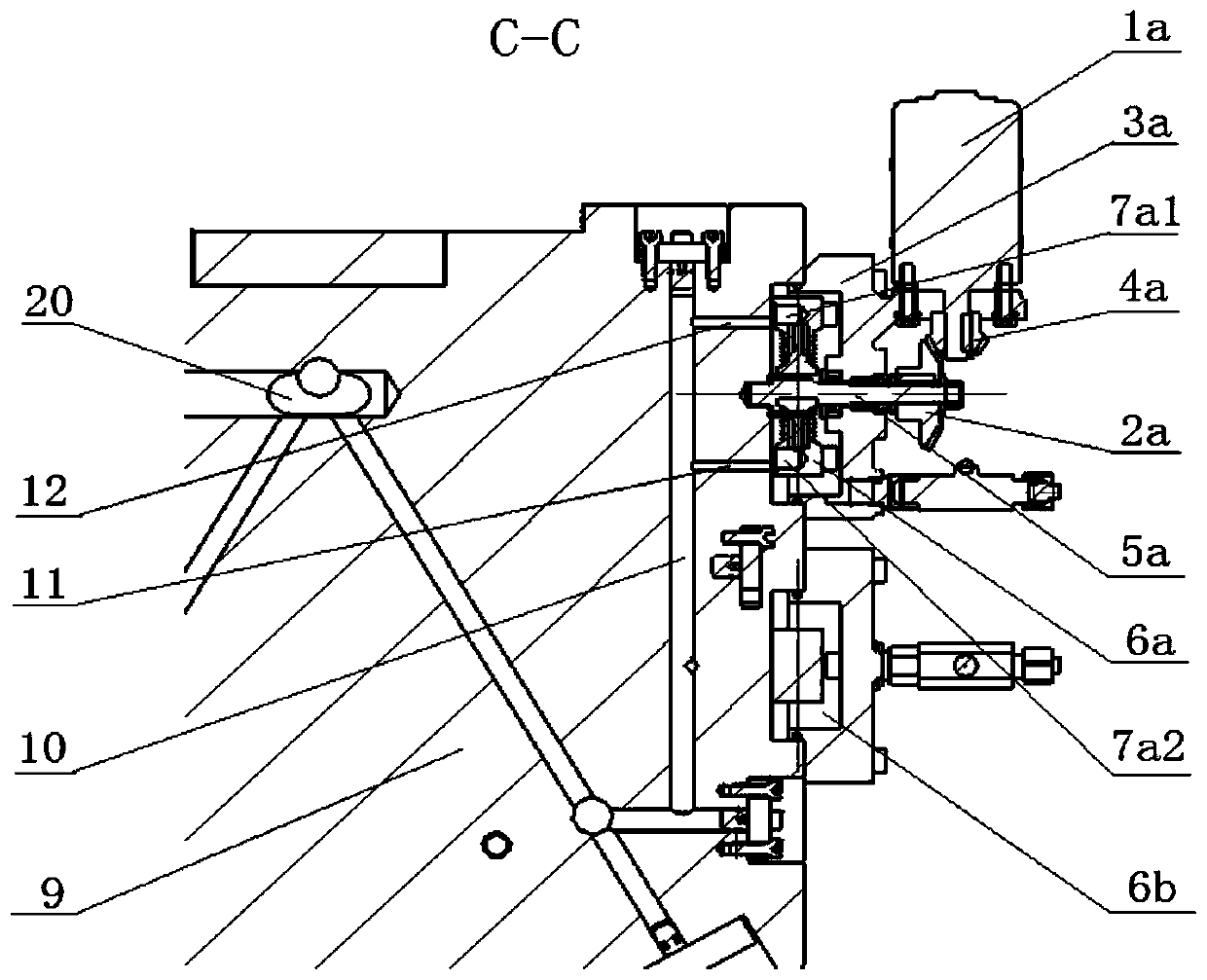

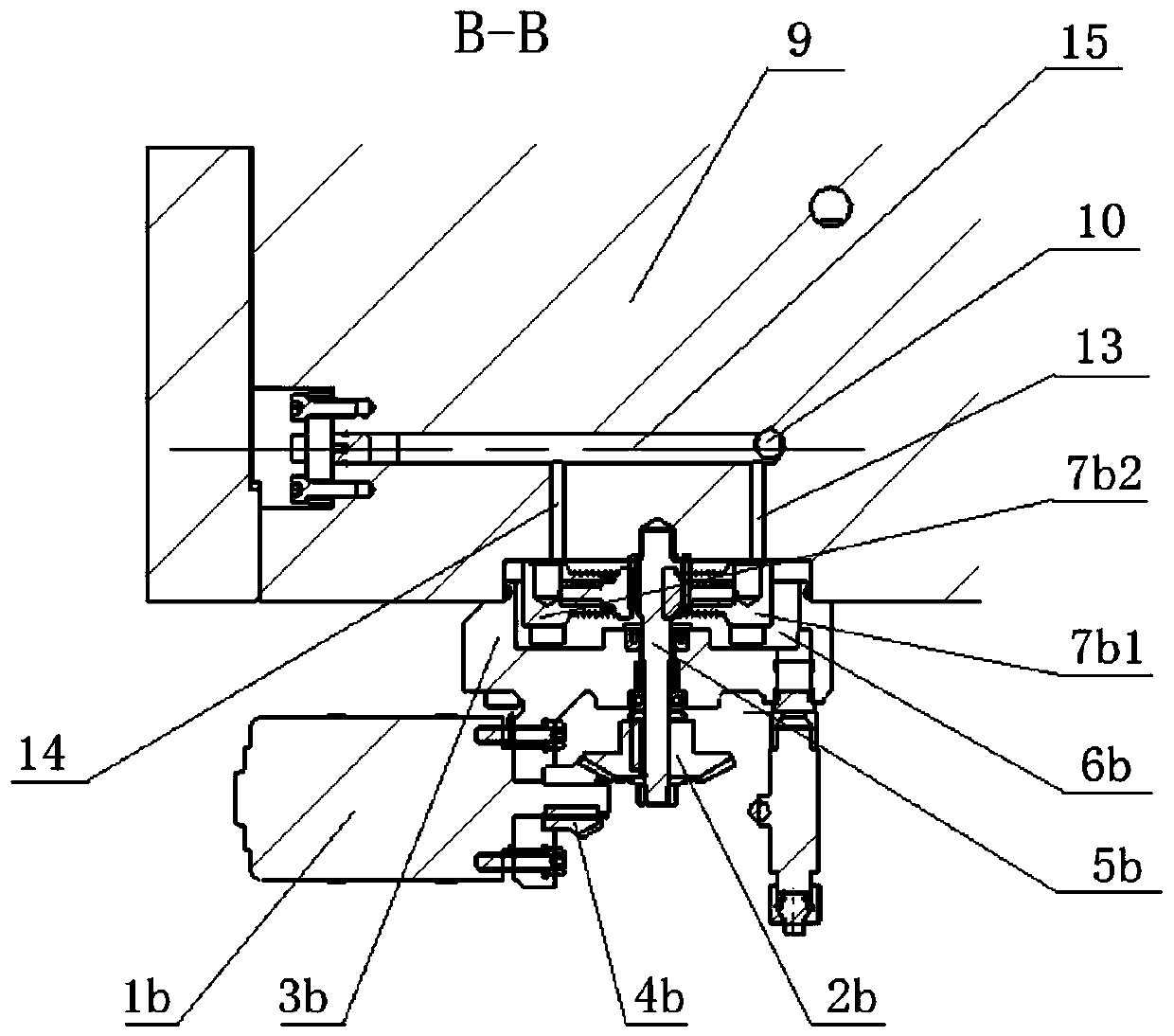

PendingCN108981497APrecise speed controlPrecise control angleSelf-propelled projectilesBody rollRocket

The invention relates to a space rocket body rolling apparatus, comprising: at least two traveling rolling mechanisms available for height adjusting and used for driving a rocket body to axially roll,wherein the traveling rolling mechanisms are arranged at the lower end of the rocket body, and at least one of the traveling rolling mechanisms is provided with a side adjusting mechanism for adjusting the axis of the rocket body; rolling rings cooperating with flanges of the rocket body and supported on the traveling rolling mechanisms; a control cabinet connected with the traveling rolling mechanisms and controlling at least one traveling rolling mechanism to operate. The problem that a traditional rocket body has uncontrollable rolling angle or cannot roll is solved; a motor with a band brake is used to control rollers to rotate or stop, rolling linear speed and angle of a barrel and a rocket body can be controlled precisely, and transmission is more stable; a single drive mode and a multi-drive mode can be freely switched according to the length and weight of the barrel; the space rocket body rolling apparatus is safe and reliable to use, simple and convenient to operate, low in time and manpower consumption, and high in automation level.

Owner:WUHU SHUANGYI AERO TECH

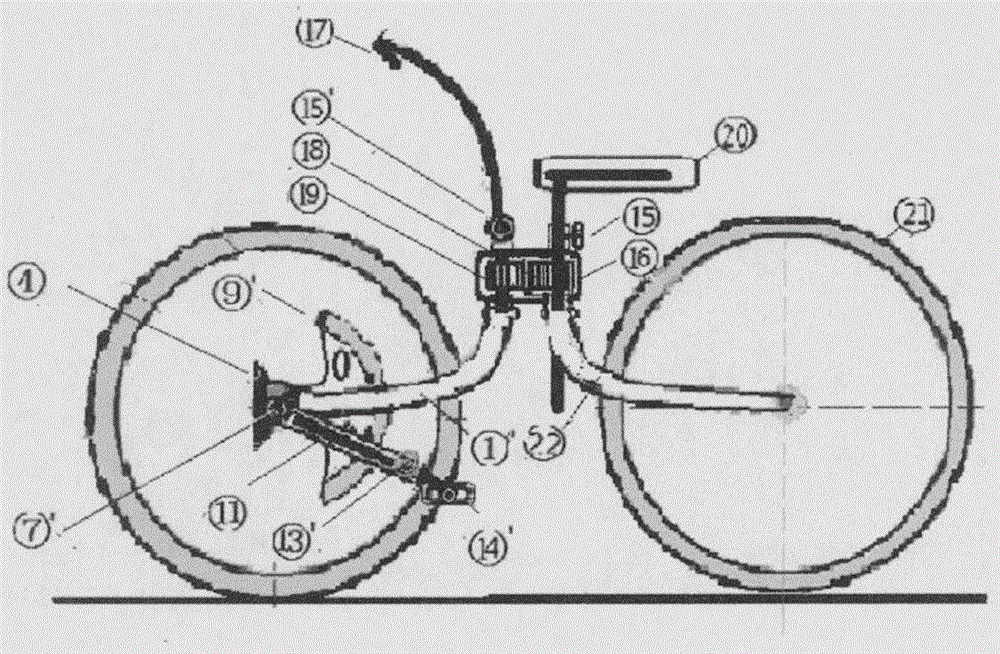

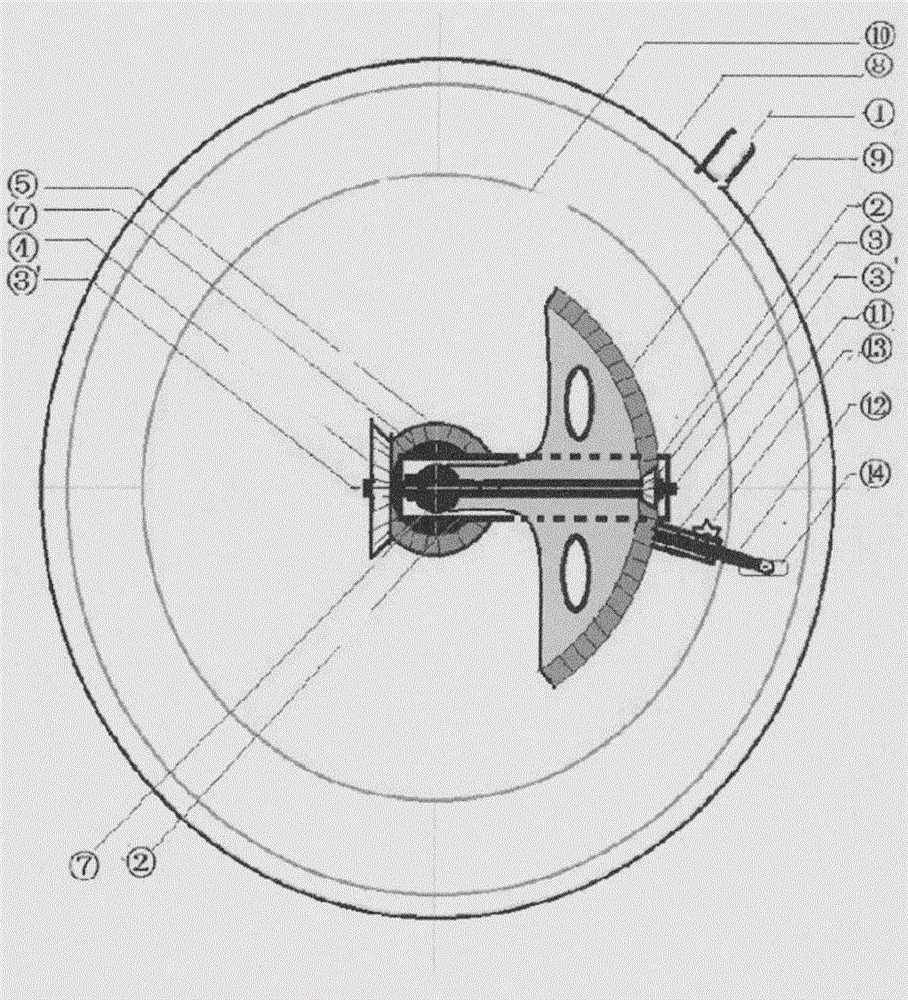

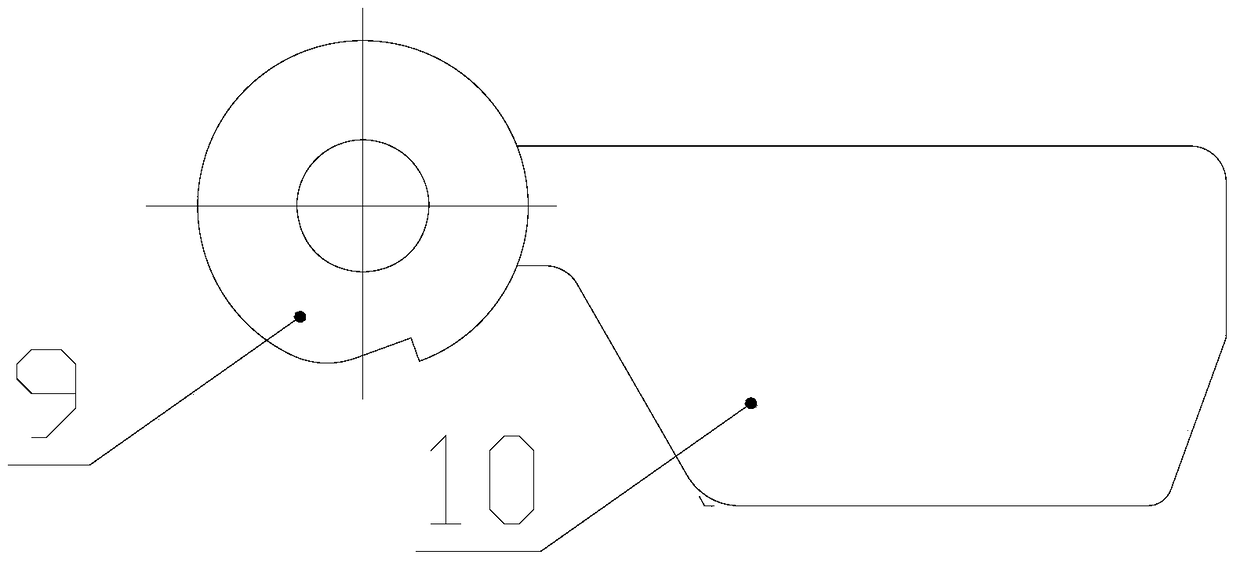

Stepping type no-chain no-middle-shaft infinitely-variable-speed folding bicycle

InactiveCN106428389AEnsuring continuous forward rotation torqueDiameter reductionWheel based transmissionFoldable cyclesGear wheelDrive shaft

The invention relates to a stepping type no-chain no-middle-axle infinitely-variable-speed folding bicycle. The stepping type no-chain no-middle-axle infinitely-variable-speed folding bicycle is characterized in that a hollow shaft, one-way bearings, gears, crank telescopic rods and the like are used for replacing an middle shaft, cranks, crank discs, a chain, flywheels, a variable speed device and the like of a bicycle in the prior art, and are arranged in composite wheel hubs, and whole close of wheels and shaft transmission parts is formed. According to the stepping type no-chain no-middle-axle infinitely-variable-speed folding bicycle disclosed by the invention, the driving form, the transmission mode, the speed change method, the appearance style and the folding situation of the bicycle throughout history are changed, and common steering of a front wheel and a rear wheel is adopted, namely that the circular pedaling driving type of the bicycle is changed into a stepping type; chain transmission or transmission shaft transmission is changed into gear transmission; the speed change through adjusting gear ratio is changed into the infinitely-variable speed change through extending (or contracting) crank rods; the functions of the middle shaft are achieved by a front shaft concurrently, and the middle shaft manner of the bicycle is omitted; and the front wheel steering is changed into the common steering of the front wheel and the rear wheel, and internal rotation and folding of the front wheel and the rear wheel are realized.

Owner:黄建

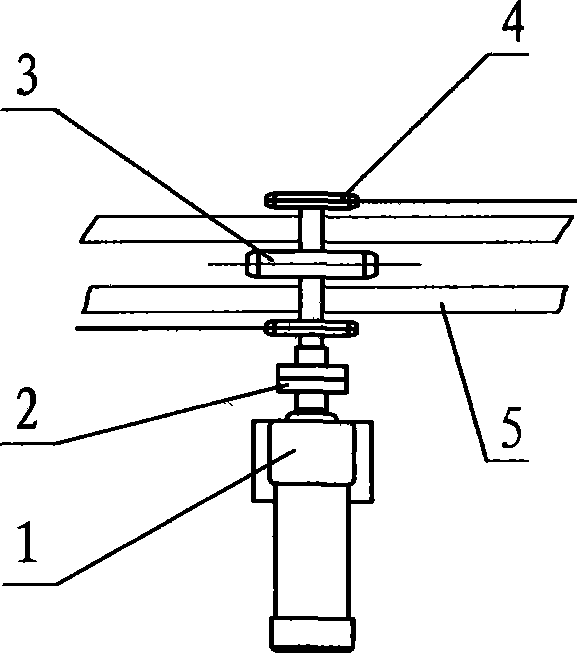

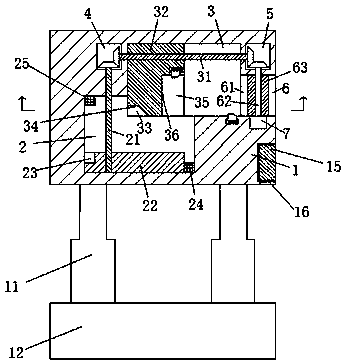

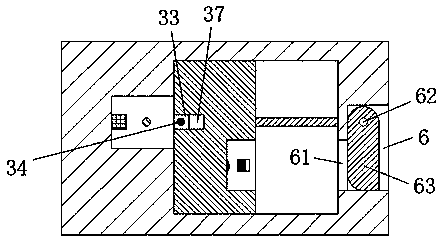

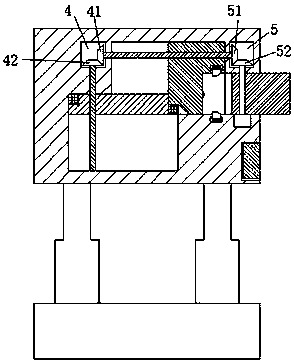

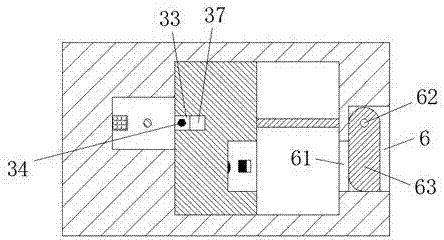

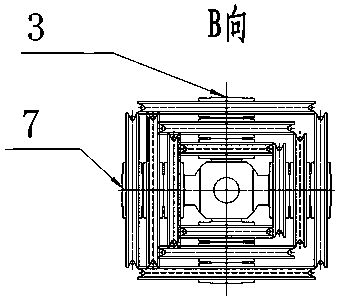

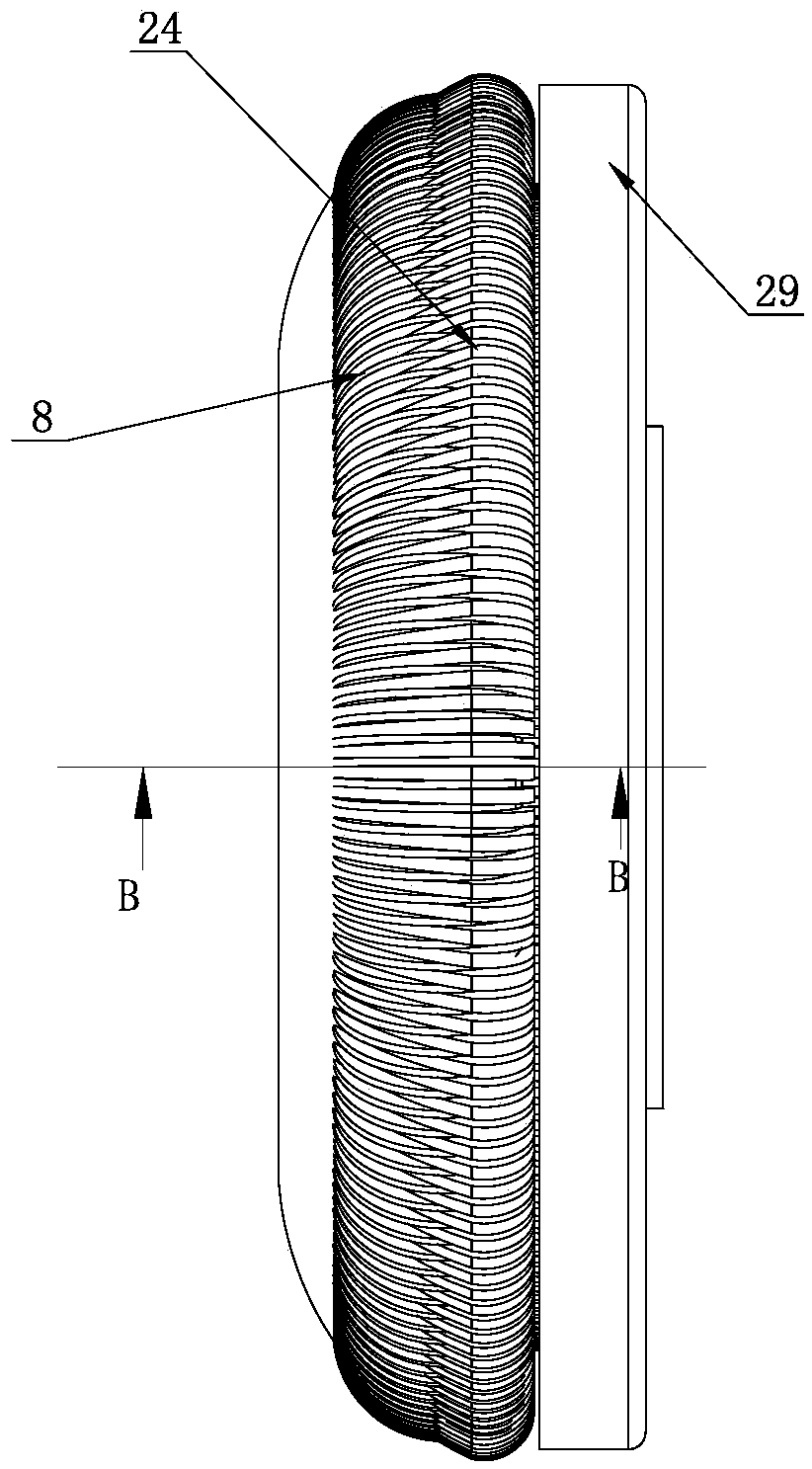

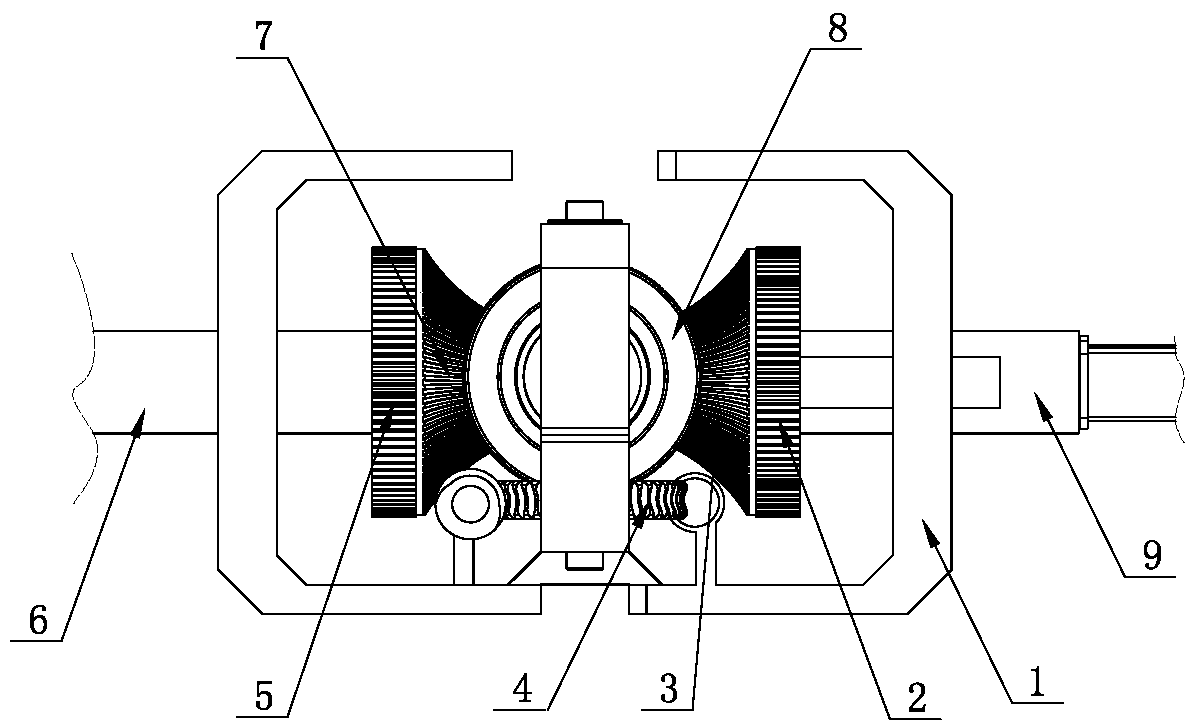

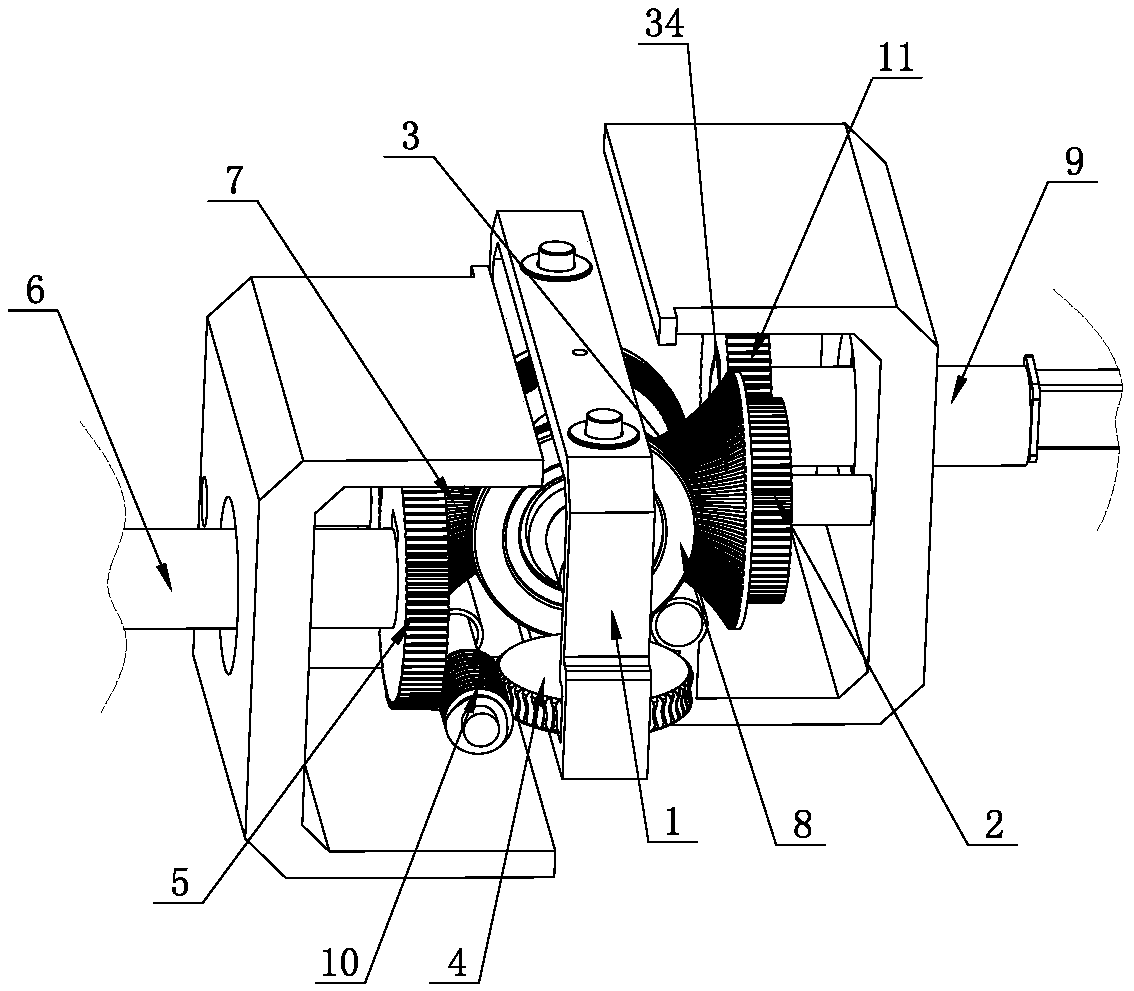

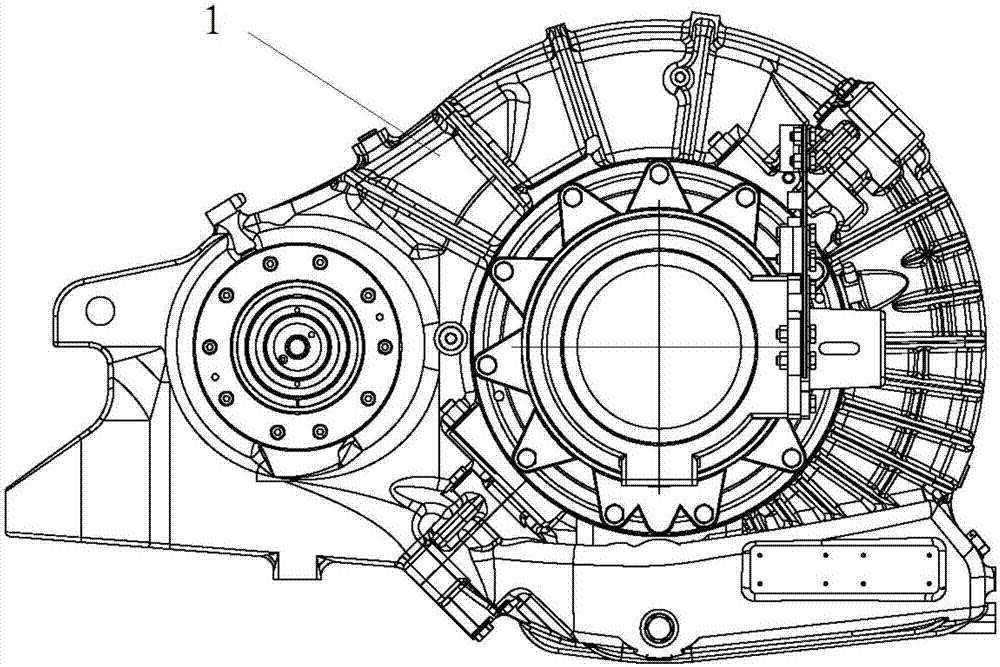

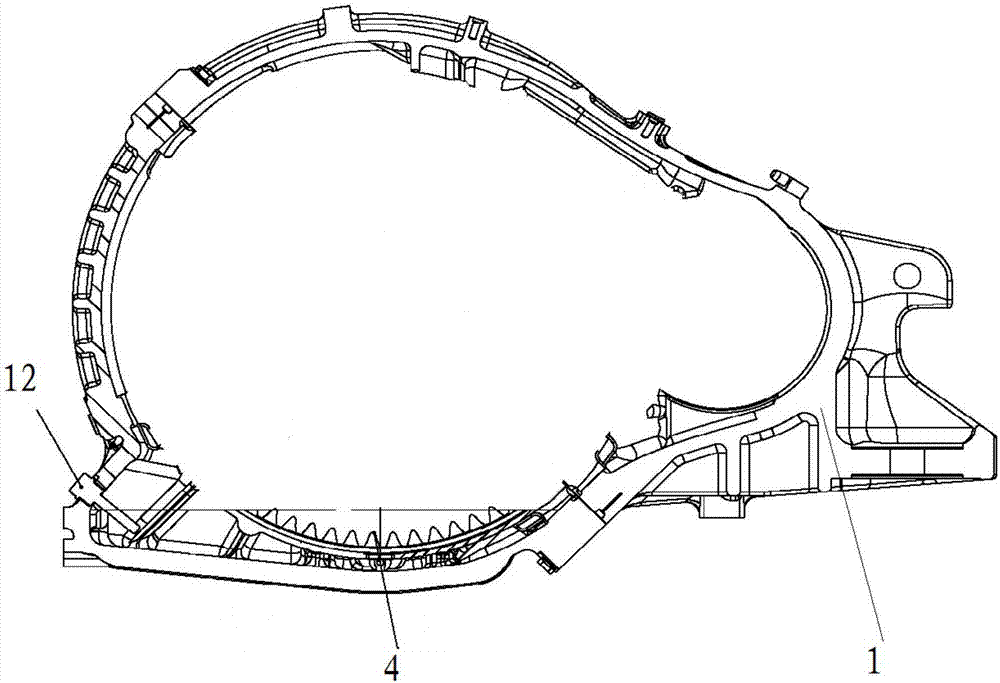

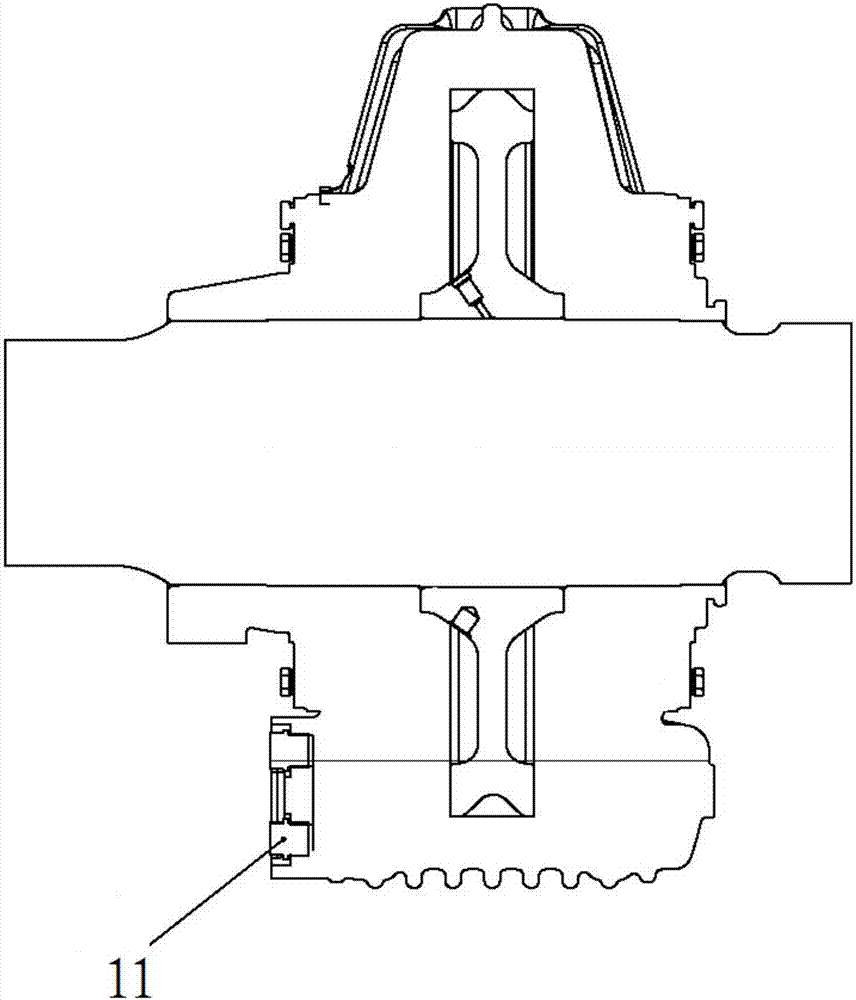

Feeding system driving coupling device of molding machine

ActiveCN102198734AReduce energy consumptionSafe and reliable transmissionTyresMoving frameMotor shaft

The invention discloses a feeding system driving coupling device of molding machine, which relates to a rubber tire machine, and more particularly to an improvement of the feeding system driving coupling device of a molding machine. The device is characterized in that one side of a feeding rack is provided with a fixed frame, the fixed frame is equipped with a guide rail which is provided with a moving frame moving horizontally along the guide rail; the fixed frame is equipped with a motor and a bearing pedestal, a lead screw passes through the bearing pedestal and is coupled with a motor shaft via a coupling sleeve, the lead screw is in fit connection with a nut which is fixed on a connecting plate, an air cylinder is fixed on the connecting plate, the connecting plate is connected with the moving frame, an air cylinder shaft is coupled with a hook which is connected with one edge of a trolley frame, and the motor shaft is equipped with an encoder. The device has the advantages of small energy consumption, safe and reliable transmission, automatic production process, high production efficiency, etc.

Owner:福建建阳龙翔科技开发有限公司

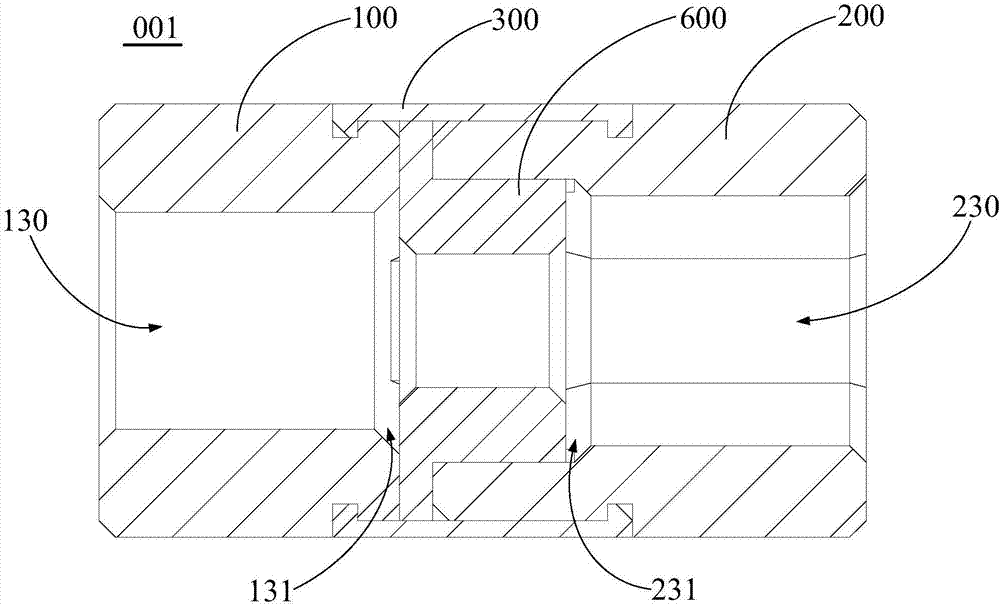

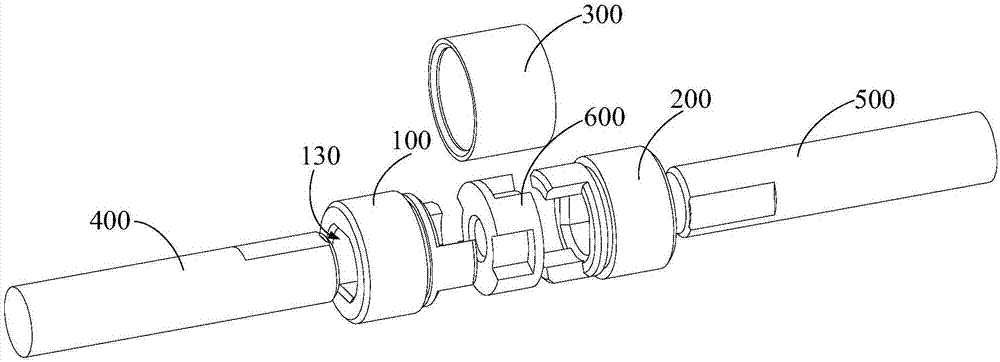

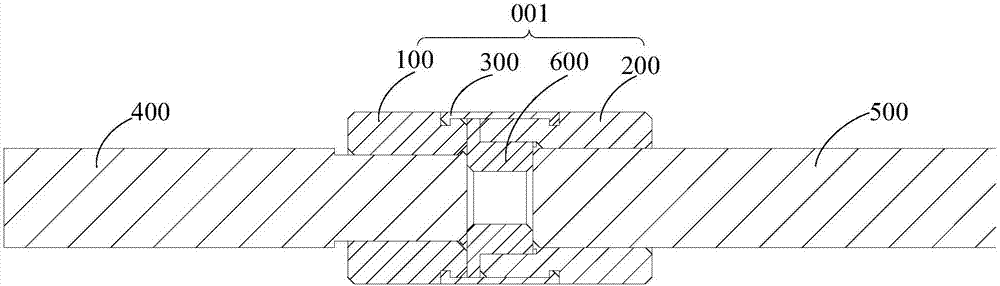

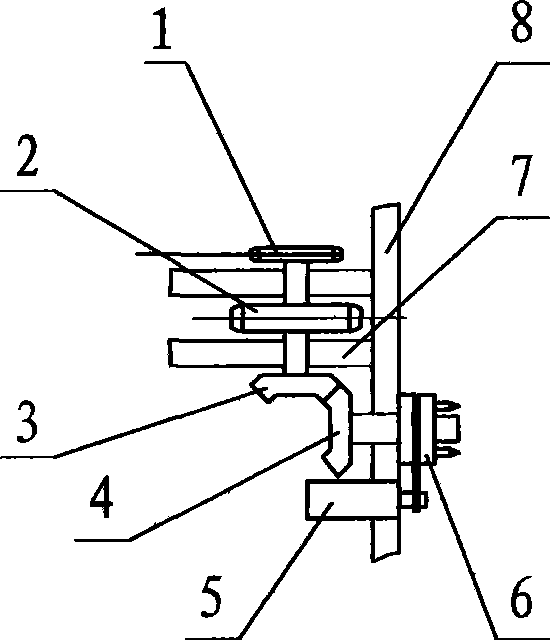

Coupler and shaft connecting structure

PendingCN107191502APrevent looseningReliable transmissionYielding couplingWind energy generationClassical mechanicsControl theory

The invention relates to the technical field of shaft transmission, in particular to a coupler. The coupler comprises a first shaft sleeve, a second shaft sleeve and an elastic limiting ring; one end of the first shaft sleeve is used for connecting with a first shaft, the other end of the first shaft sleeve is used for transmission connection with one end of the second shaft sleeve, and the other end of the second shaft sleeve is used for being connected with a second shaft; and the elastic limiting ring sleeves the connecting position of the first shaft sleeve and the second shaft sleeve, and therefore looseness of the first shaft sleeve and the second shaft sleeve is prevented. According to the coupler, the first shaft sleeve and the second shaft sleeve are used for connecting the first shaft and the second shaft correspondingly, the first shaft sleeve and the second shaft sleeve are in transmission connection, and therefore torque transmitting can be achieved through the first shaft and the second shaft; meanwhile, the elastic limiting ring sleeves the connecting position of the first shaft sleeve and the second shaft sleeve so as to prevent looseness of the first shaft sleeve and the second shaft sleeve, and therefore transmission connection of the first shaft sleeve and the second shaft sleeve is more reliable, and transmission of the first shaft and the second shaft is safer and more reliable.

Owner:GREE ELECTRIC APPLIANCES INC

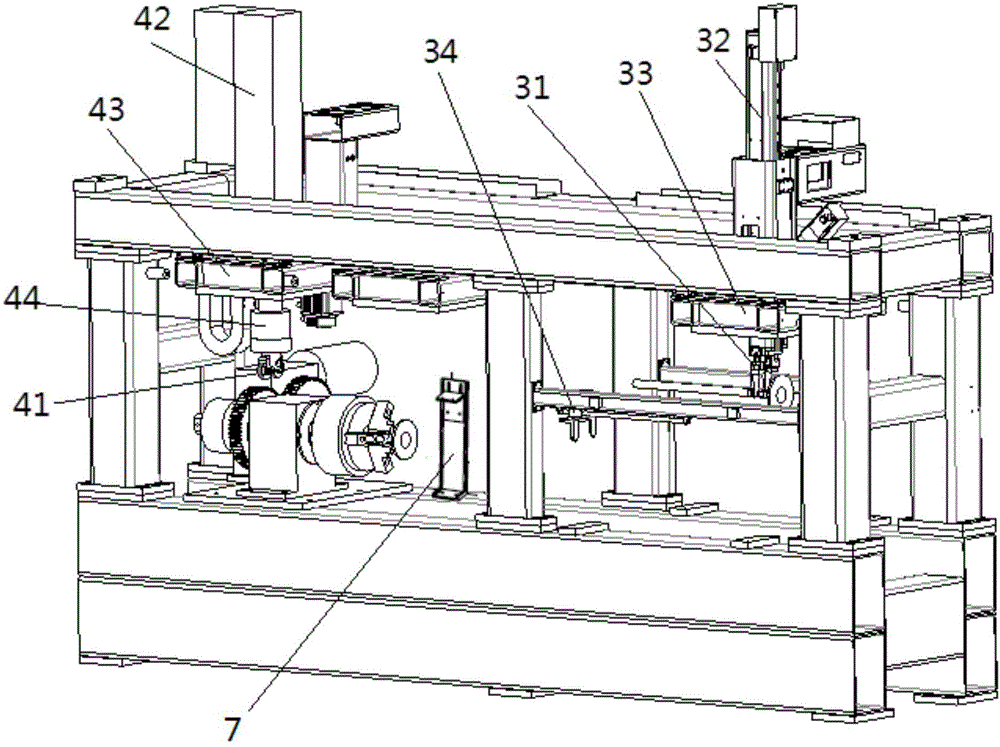

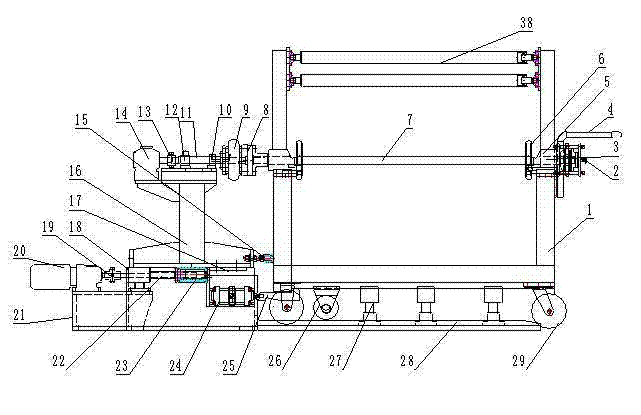

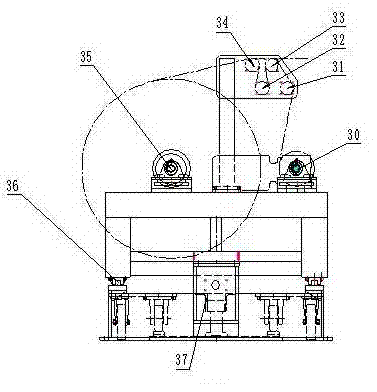

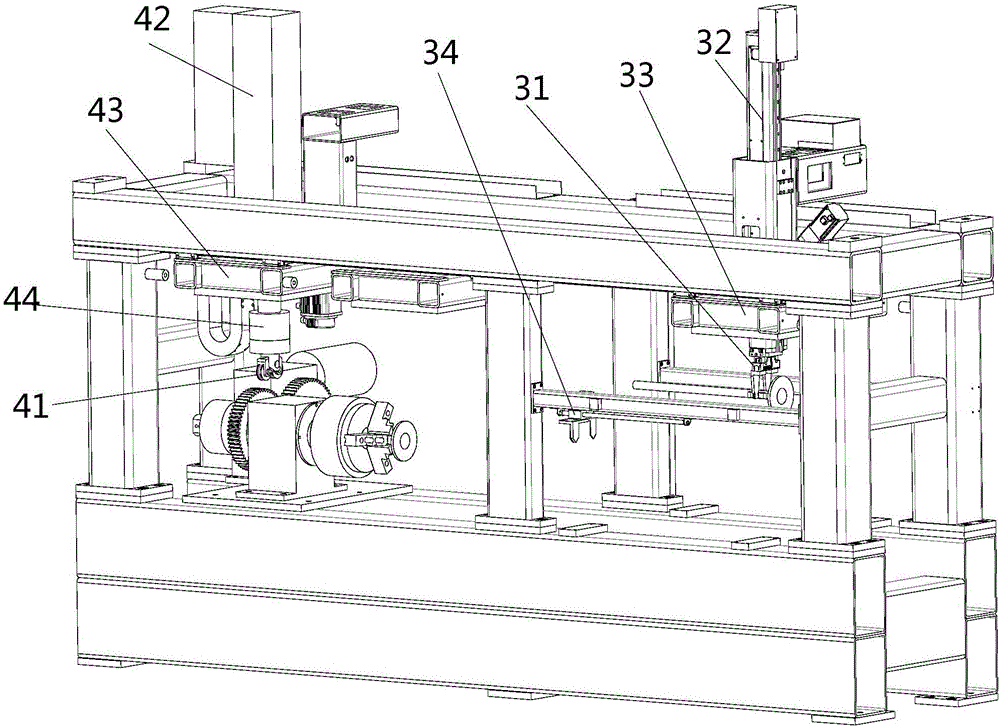

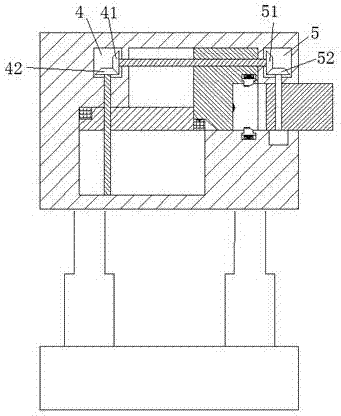

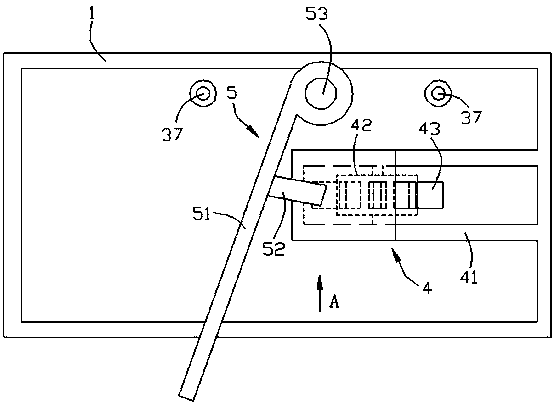

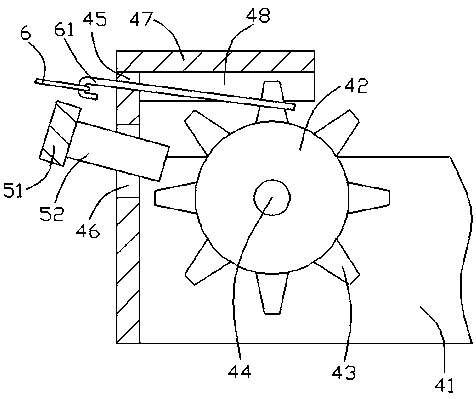

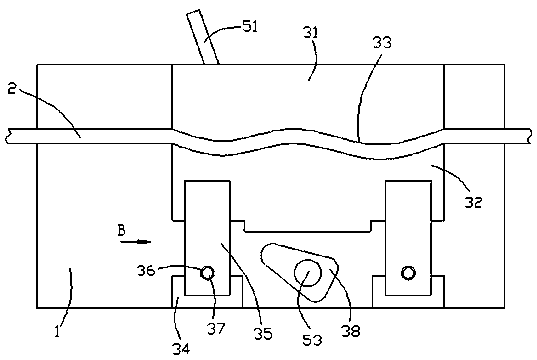

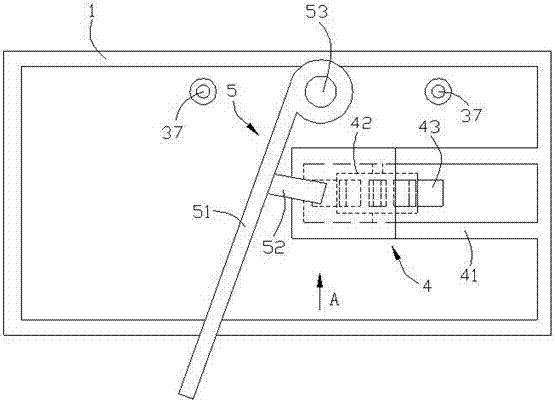

Automated equipment used for detecting yield strength of valve friction welding

ActiveCN106769469AHigh degree of automationImprove work efficiencyMaterial strength using tensile/compressive forcesConveyor partsHydraulic cylinderFriction welding

The invention discloses automated equipment used for detecting the yield strength of valve friction welding. The automated equipment comprises an automatic feeding and discharging conveying mechanism, a feeding and discharging mechanical arm module, an electric cylinder loading module and a hydraulic chuck clamping mechanism, wherein the feeding and discharging mechanical arm module comprises a pneumatic mechanical arm; the electric cylinder loading module comprises a pressure plate, a servo electric cylinder, a third driving mechanism, a pressure sensor and a grating ruler; the hydraulic chuck clamping mechanism comprises a rotary main shaft, a hydraulic chuck, a chuck pull rod hydraulic cylinder and a fourth driving mechanism; the pneumatic mechanical arm moves a valve to clamping fingers on the front end of the hydraulic chuck; the rod part of the valve is clamped through the clamping fingers and is pressed to the head of the valve through the pressure plate of the electric cylinder loading module so as to detect the yield strength of the valve friction welding. The automated equipment has the advantages that the whole course automation of valve feeding and discharging, valve clamping and cantilever loading for the valve can be realized so as to realize the automatic detection of the yield strength of valve friction welding.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

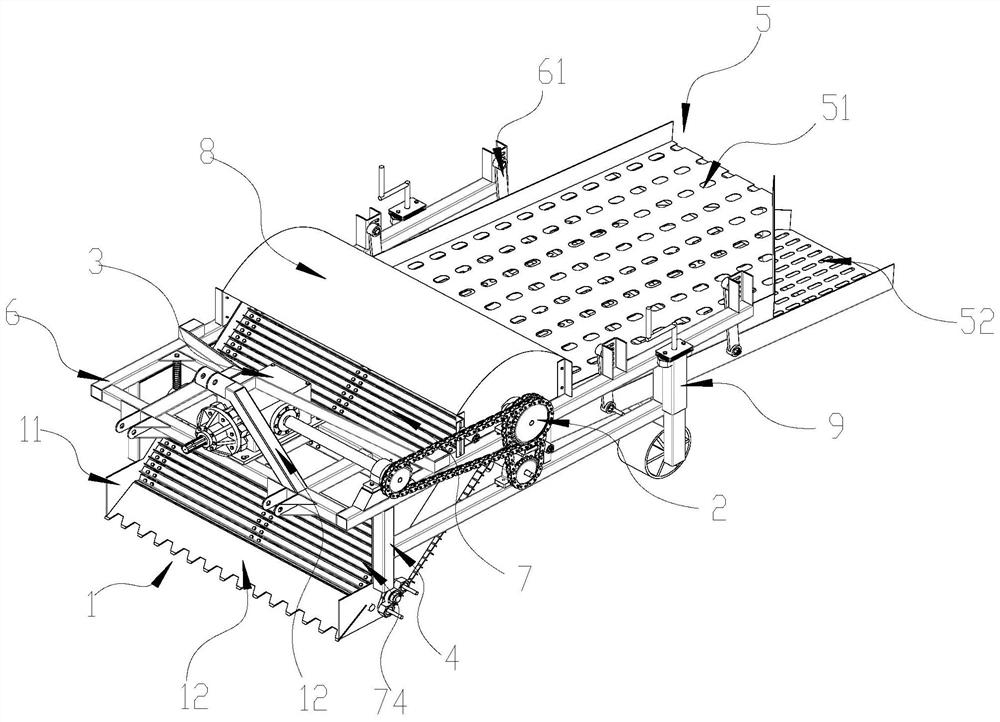

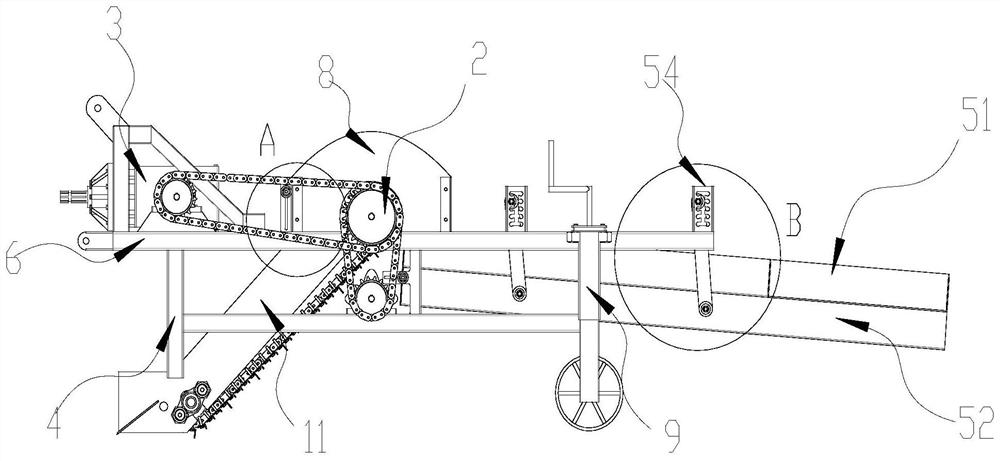

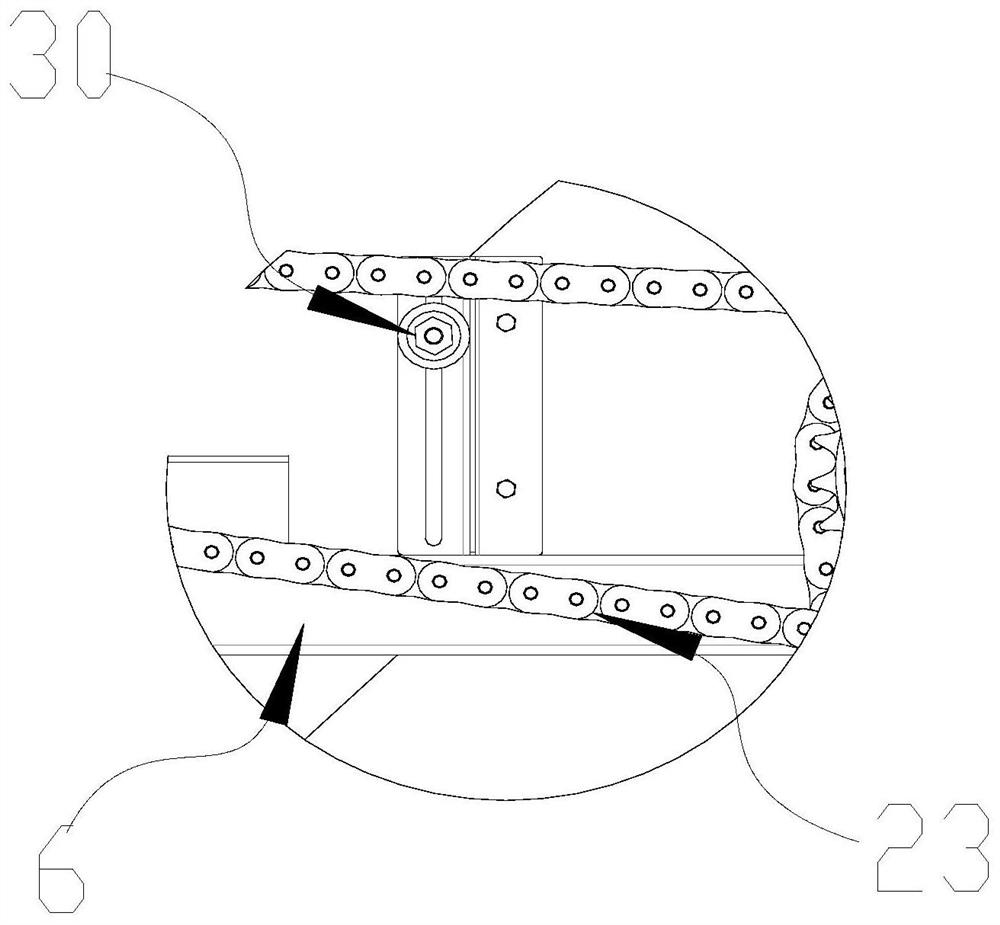

Plain shellfish collecting device

InactiveCN112189429AQuality improvementCompact structureDiggersAgricultural engineeringAgricultural machinery

The invention relates to the technical field of agricultural machinery, and discloses a shellfish collecting device which comprises an excavating mechanism, a transmission mechanism, a speed reducer,a rack, a supporting frame, a screening mechanism, a conveying mechanism and a rolling mechanism. The rack and the supporting frame are both of a frame structure, and the rack is fixedly connected tothe top of the supporting frame. The excavating mechanism can rotate within a small range and is connected to the lower left portion of the rack. The conveying mechanism is located on the inner side of the rack and connected with the excavating mechanism; the speed reducer is fixedly connected to the left side of the rack; the transmission mechanism is located on the front side of the rack, and the speed reducer is connected with the transmission mechanism; the transmission mechanism is connected with the conveying mechanism; the rolling mechanism is arranged above the conveying mechanism; thescreening mechanism is arranged on the right side of the rack and fixedly connected with the rack, and the screening mechanism is connected with the conveying mechanism. The problems that in the prior art, flat shellfish harvesting machines are few, cannot be popularized in production, and are poor in harvesting effect, low in screening efficiency and complex in structure are solved.

Owner:NORTHEAST FORESTRY UNIVERSITY

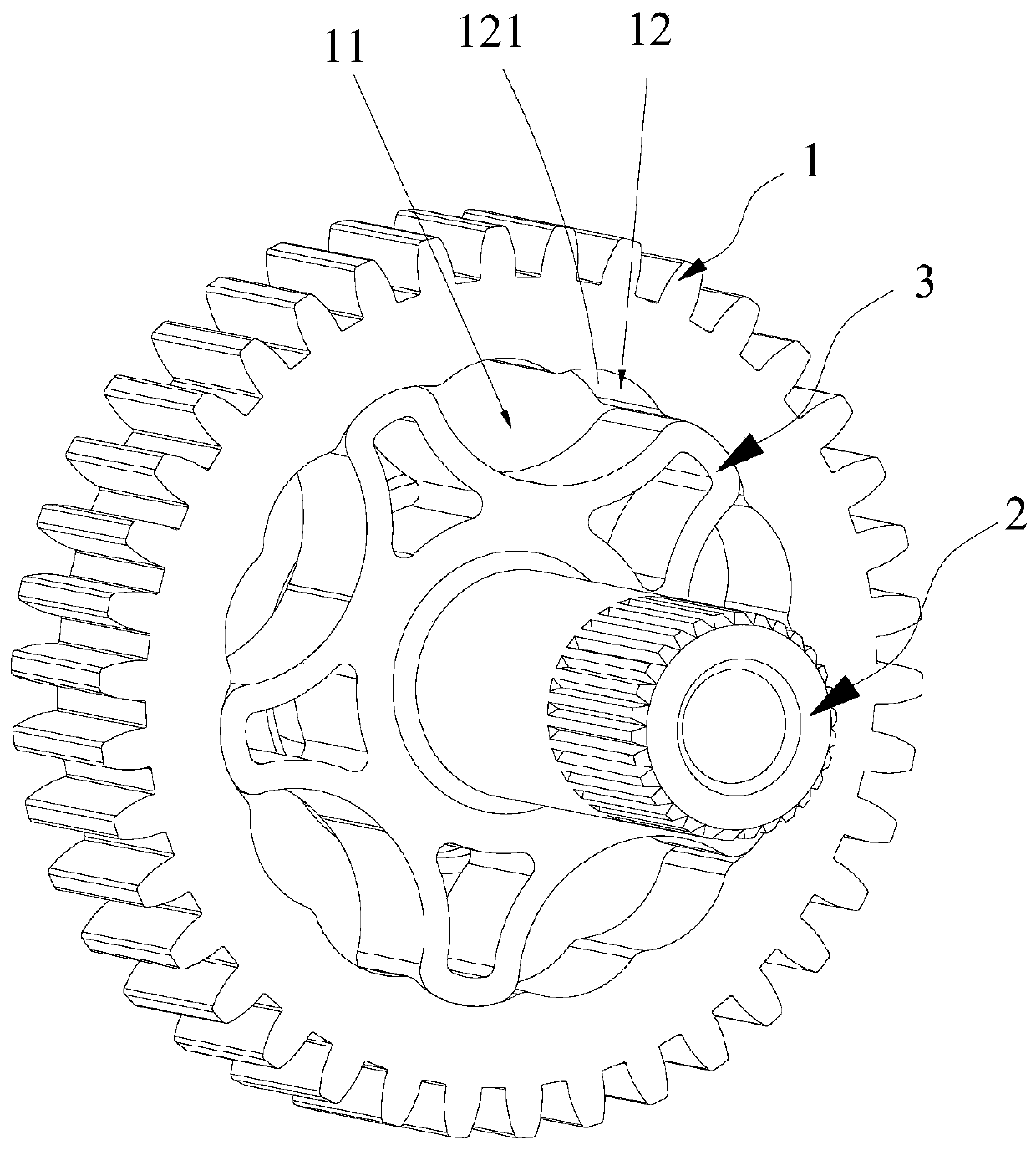

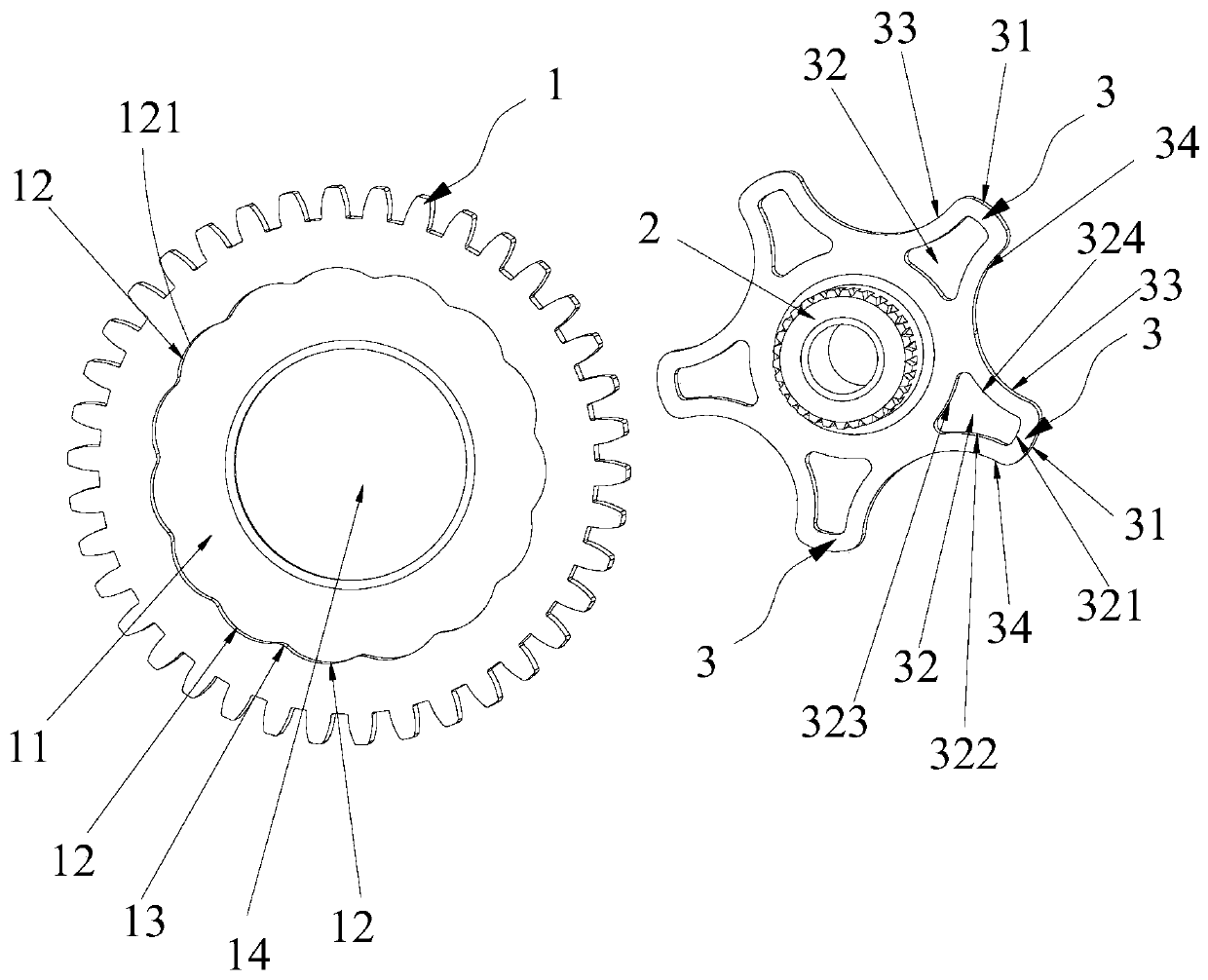

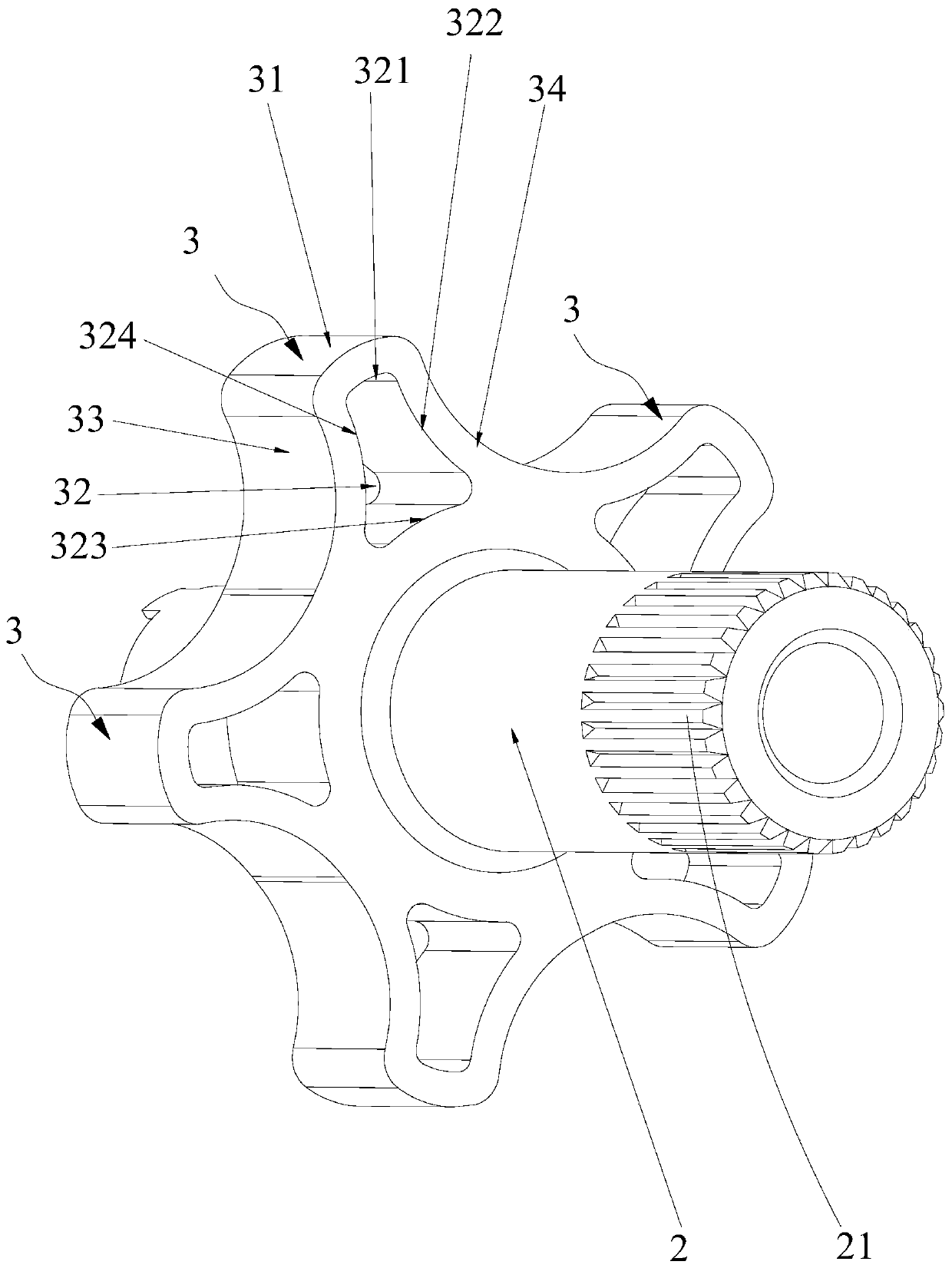

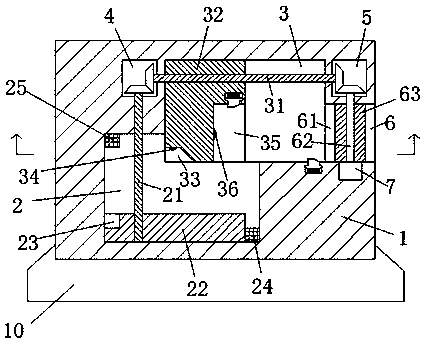

Clutch, steering engine and robot

ActiveCN111015643AIncreased contact areaImprove stabilityProgramme-controlled manipulatorGear wheelEngineering

The invention discloses a clutch. The clutch comprises an output gear, a rotating shaft and at least one clutch tooth arranged on the rotating shaft, wherein the output gear is provided with a containing groove; the inner side wall, positioned in the containing groove, of the output gear is provided with a plurality of inner tooth grooves matched with the clutch teeth; the ends, away from the rotating shaft, of the clutch teeth are provided with first contact arc faces; the inner tooth grooves are provided with second contact arc faces making contact with the first contact arc faces; the clutch teeth are provided with deformation holes; and the first contact arc faces are arranged at the positions where the clutch teeth make contact with the output gear, that is, the tops of the clutch teeth are of a cylindrical structure, compared with an involute type gear, the contact area of the clutch teeth is larger, and vibration in the transmission process can be effectively reduced. Meanwhile,the second contact arc faces are arranged in the inner tooth grooves of the output gear and make contact with the first contact arc faces of the clutch teeth, and therefore when clutch slipping happens, due to the fact that the first contact arc faces and the second contact arc faces are gentle, tooth jumping is easily achieved to achieve safe clutch.

Owner:UBTECH ROBOTICS CORP LTD

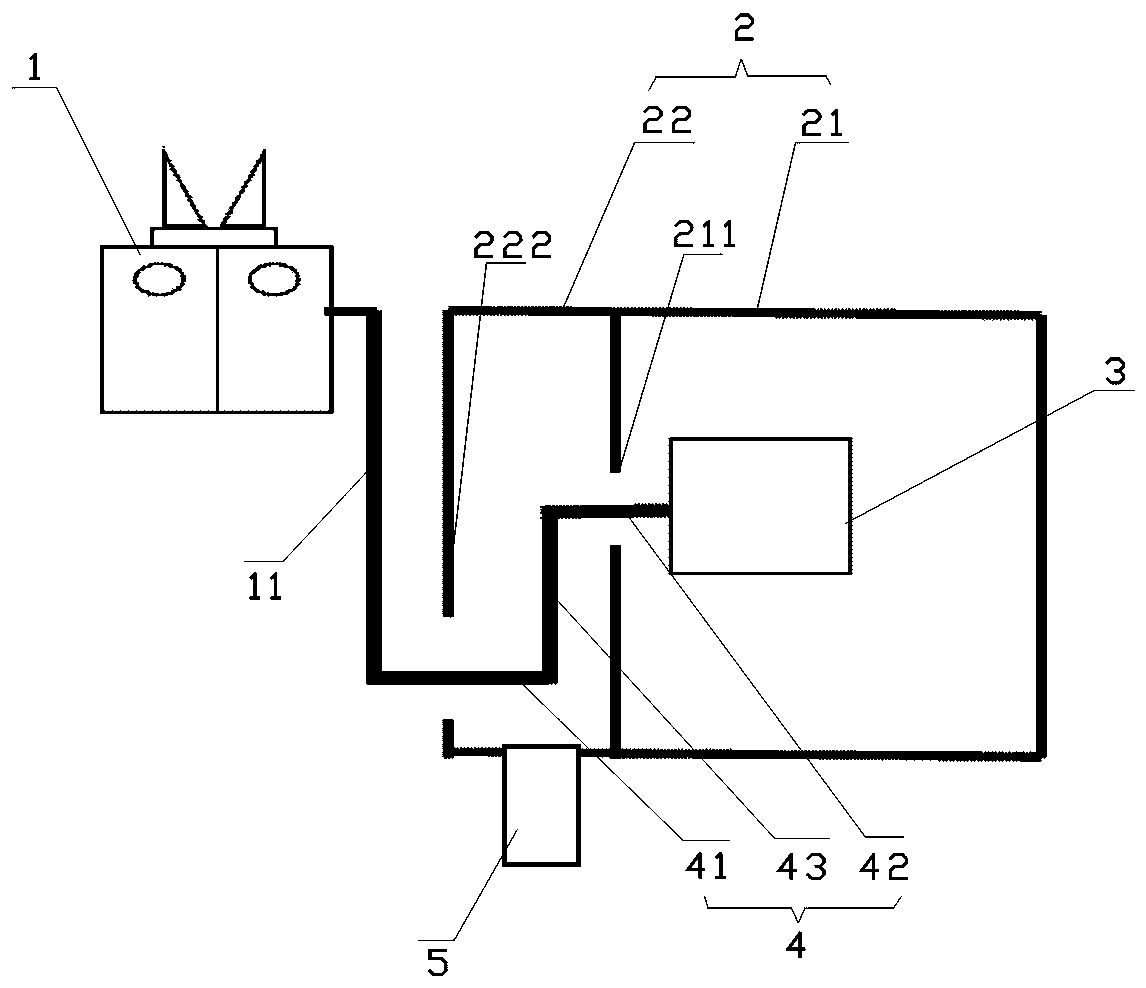

Parking equipment access exchanging system

InactiveCN101435275AInsert smoothlySafe and reliable power transmissionParkingsSprocketMechanical drive

Disclosed is a parking equipment access relay system, which is composed of a feeding frame, a power part, a drive device, a relay device, and a carrier vehicle supporting plate, and is arranged in mechanical parking equipment for putting vehicle at berth or getting the vehicle from the berth, relating to the technical field of steel structure and mechanical drive. A synchronous sprocket wheel is adopted to drive the carrier vehicle supporting plate, taper pin clutch relay transmission is provided, the access relay is novel and unique, and simple and easy, not only the machining cost is reduced, but also the transmission is more reliable.

Owner:蓝家瑞

Novel new energy automobile equipment

InactiveCN108233035ASafe and reliable transmissionSmooth transmissionVehicle connectorsCharging stationsNew energyEngineering

The invention discloses novel new energy automobile equipment comprising a charging pile body. The bottom part of the charging pile body is provided with a hydraulic telescopic pump. The bottom part of the hydraulic telescopic pump is fixedly provided with a baseplate. The charging pile body is provided with a second slide slot and a first slide slot which is arranged on the rear end of the secondslide slot. The charging pile body of the left and right ends of the first slide slot is respectively provided with a left side toothed slot and a right side toothed slot. The right end surface of the charging pile body is provided with a closed slot. A jack slot is connected between the closed slot and the first slide slot. The rear part of the first slide slot is provided with left and right spiral rods which jack into the left side toothed slot and the right side toothed slot to be rotatably and cooperatively connected with the charging pile body. The overall structure is simple, the production cost is low and power supply is safe and stable.

Owner:广西途美兴汽车服务有限责任公司

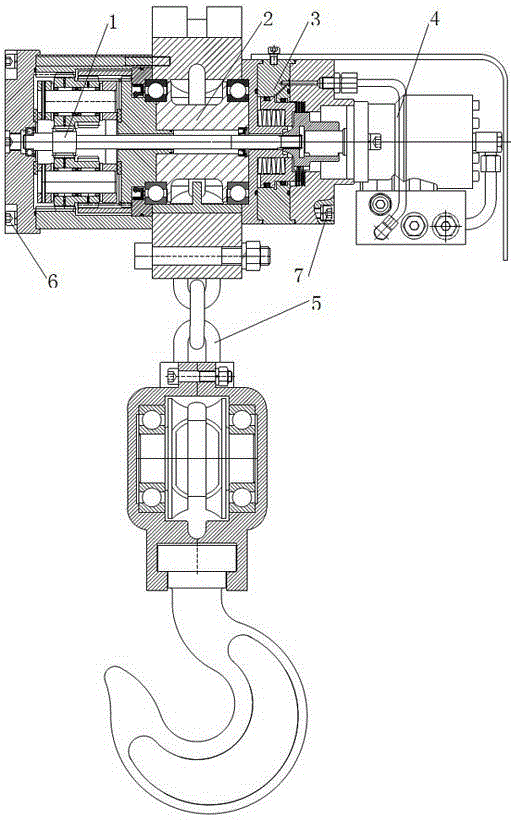

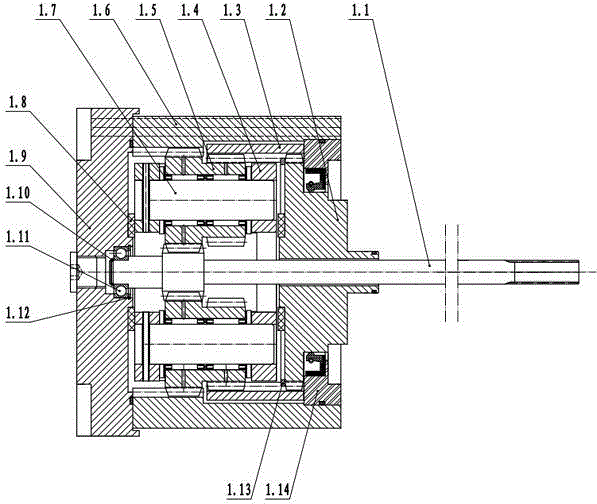

Mine vehicle-mounted hydraulic winch

The invention belongs to the technical field of traction equipment, and particularly relates to a mine vehicle-mounted hydraulic winch, which is matched with a mine auxiliary transporting vehicle and aims at solving the problems of the existing hydraulic winch. The mine vehicle-mounted hydraulic winch comprises a planetary speed reducer, a chain mechanism, a brake, a hydraulic motor assembly and a circular chain, wherein the planetary speed reducer, the chain mechanism, the brake and the hydraulic motor assembly are sequentially connected to form a sealed structure, and the brake is provided with disc springs and adopt the multi-disc spring dry brake and counterbalance valve brake double-action type. The mine vehicle-mounted hydraulic winch has the advantages that the mine vehicle-mounted hydraulic winch is especially suitable for auxiliary transporting equipment in coal mine wells; the structure is compact, the traction force is large, the brake is safe and reliable, and the working efficiency is high.

Owner:TAIYUAN INST OF CHINA COAL TECH & ENG GROUP +2

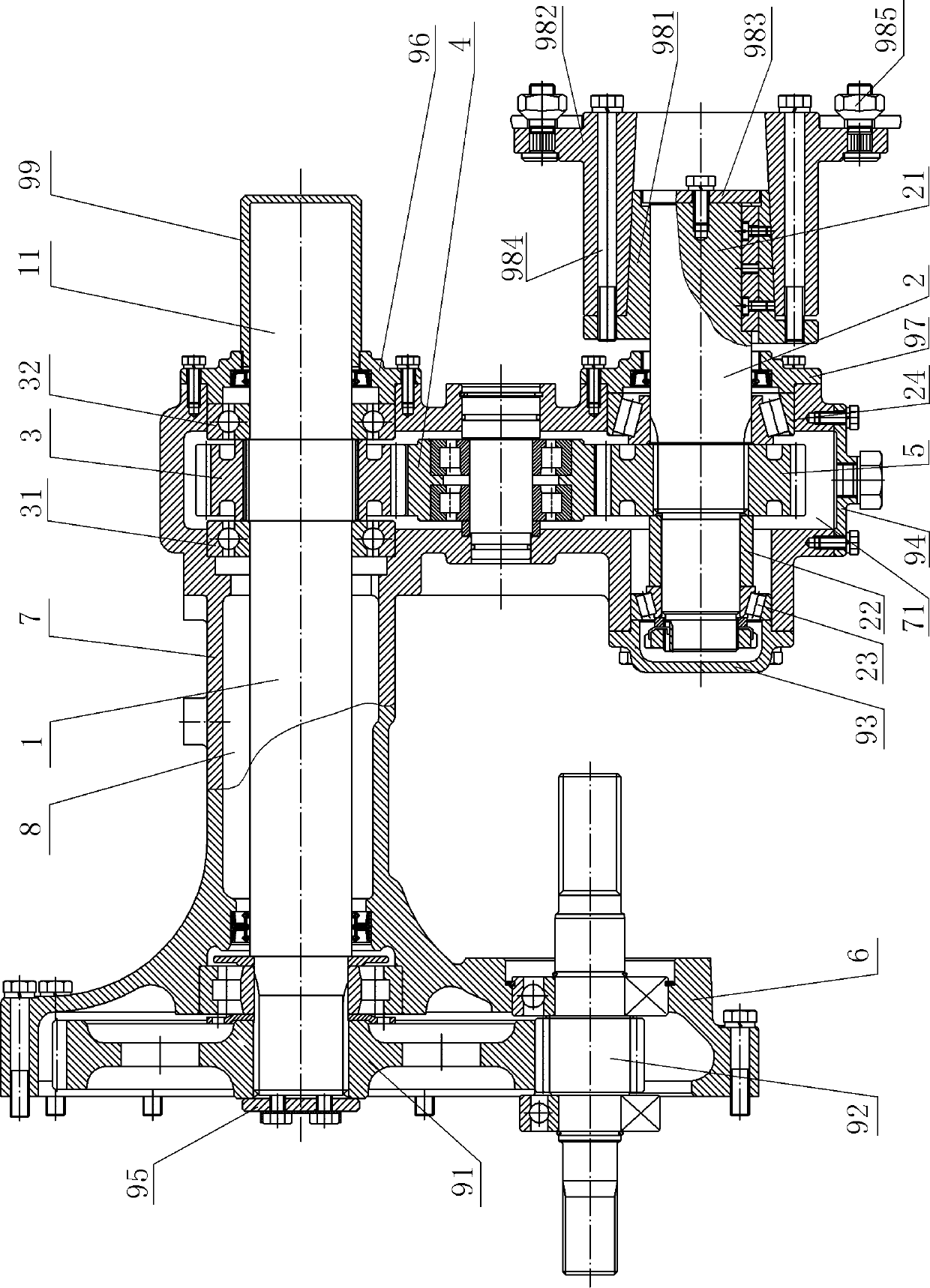

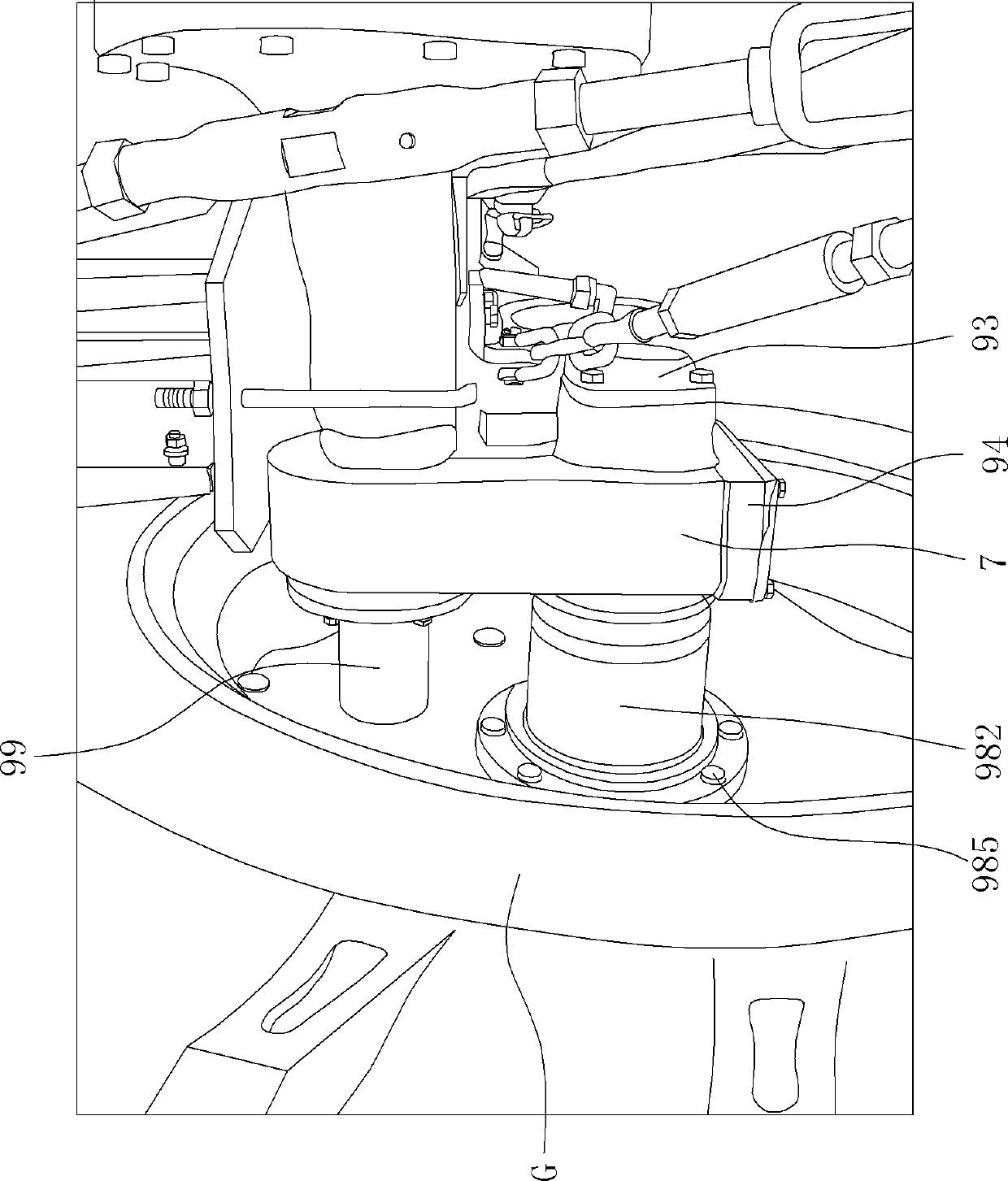

Ground-clearance-adjustable tractor transmission system

Owner:宁波兴野拖拉机制造有限公司

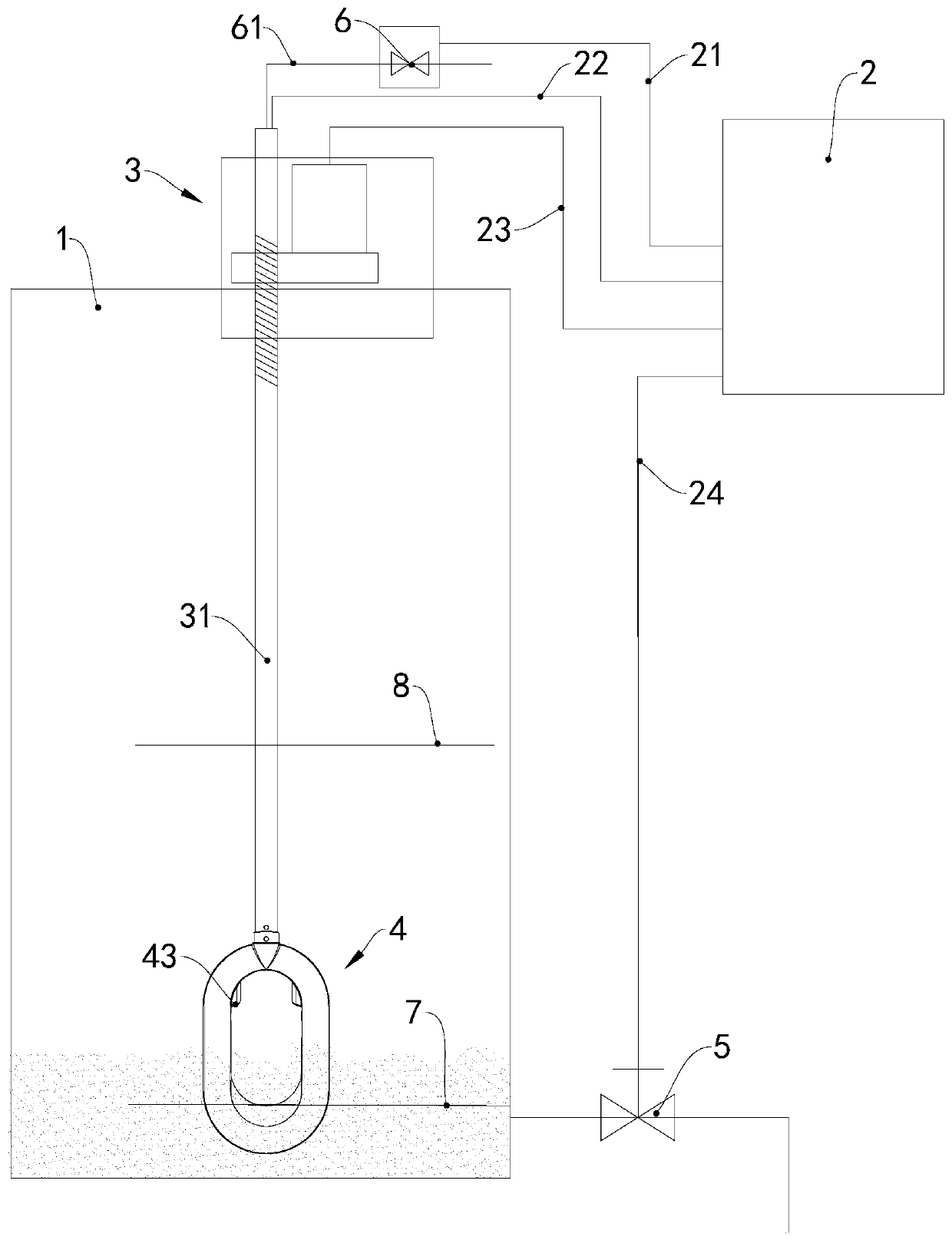

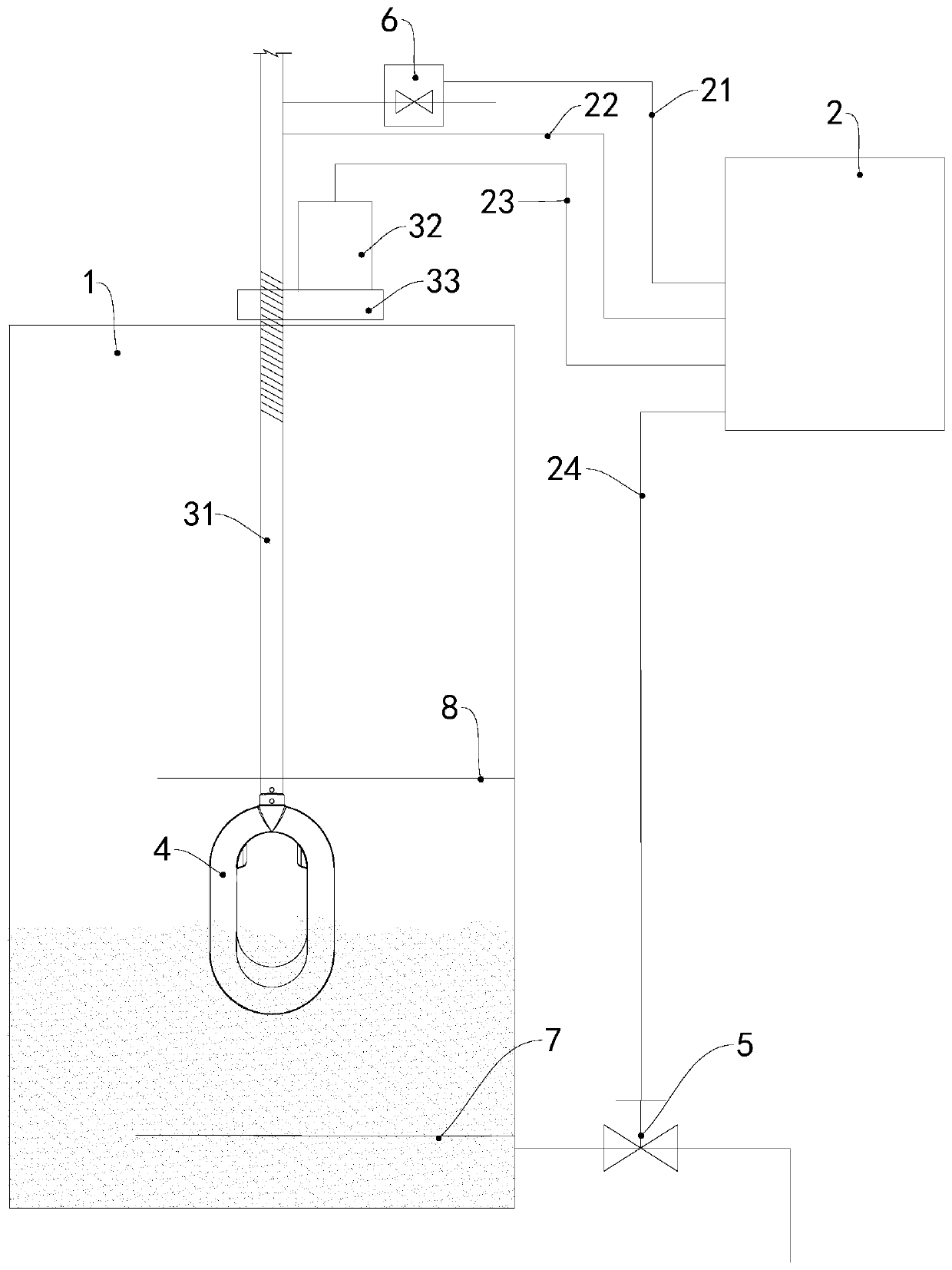

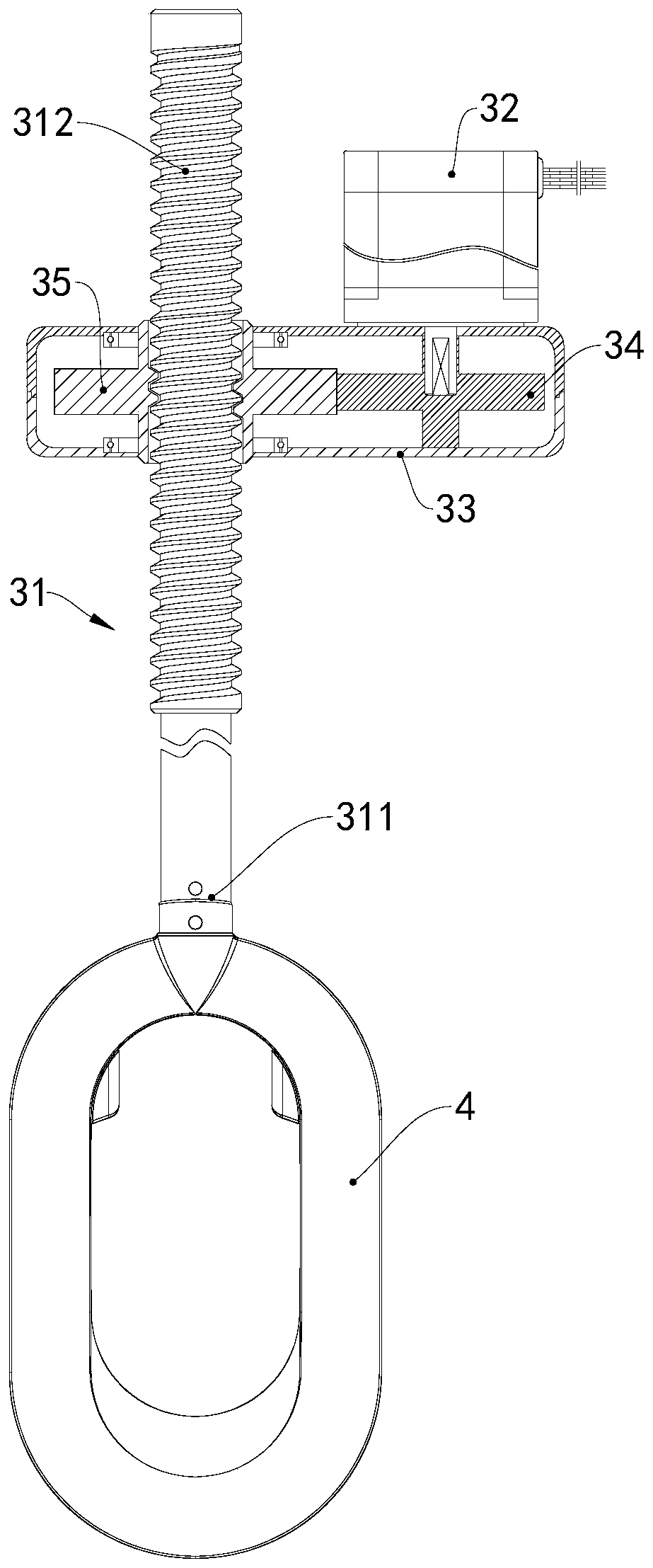

Material level control system, control method and water treatment tank

ActiveCN111517388AAccurate monitoringAccurate trackingWater treatment parameter controlLevel controlControl systemSludge

The invention discloses a material level control system, a control method and a water treatment tank, and relates to the technical field of water purification treatment. The material level control system comprises a control unit and a detection unit, the control unit receives signals of the detection unit, a lifting device comprises a lifting rod, and the detection unit is fixed to the lower end of the lifting rod. The control unit is used for controlling the lifting device according to a sludge level signal sent by the detection unit, so that the detection unit is lifted. The method comprisesa setting step, a tracking ascending step and a tracking descending step. A water treatment tank adopts the material level control system. The system has the advantages of accurate monitoring, waterquality improvement and cost reduction.

Owner:ZHUHAI 9TONE WATER DEV

New energy automobile device

ActiveCN107139758ASafe and reliable transmissionSmooth transmissionCharging stationsElectric vehicle charging technologyNew energyEngineering

The invention discloses a new energy automobile device. The device comprises a charging pile body, wherein hydraulic telescopic pumps are arranged on the bottom of the charging pile body, a baseplate is fixedly arranged on the bottoms of the hydraulic telescopic pumps, and a second sliding groove and a first sliding groove which is located at the back end of the second sliding groove are formed in the charging pile body; a left side meshing groove and a right side meshing groove are formed in the left end and the right end, of the first sliding groove, in the charging pile body respectively, a sealing groove is formed in the right end face of the charging pile body, and a socket groove is communicated between the sealing groove and the first sliding groove; a left-and-right heliciform rod which is rotatably connected with the charging pile body in a matched mode is arranged on the back portion of the first sliding groove, wherein two ends of the left and right heliciform rod extend into the left side meshing groove and the right side meshing groove. The new energy automobile device is simple in structure, lower in production cost and stable in power supply safety.

Owner:JIANGSU XIYI HIGH NEW DISTRICT TECH DEV CO LTD

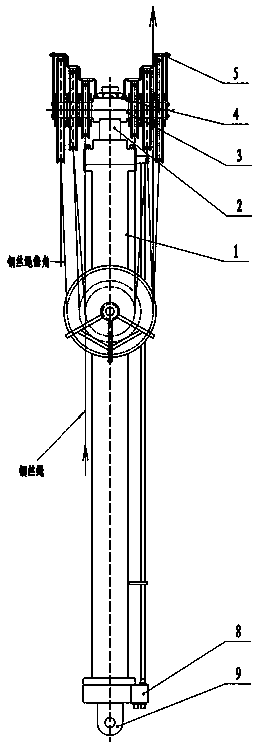

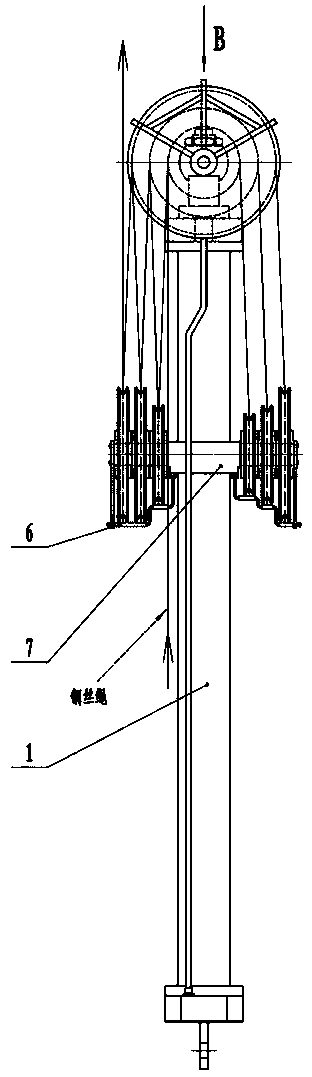

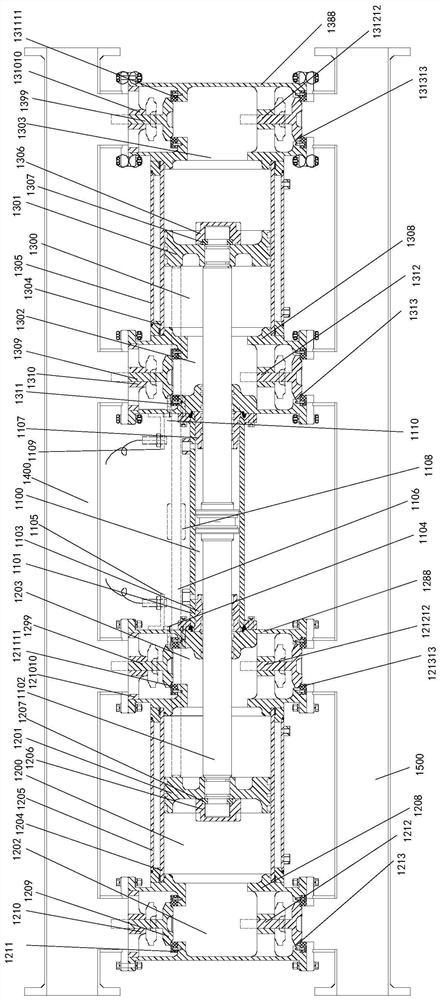

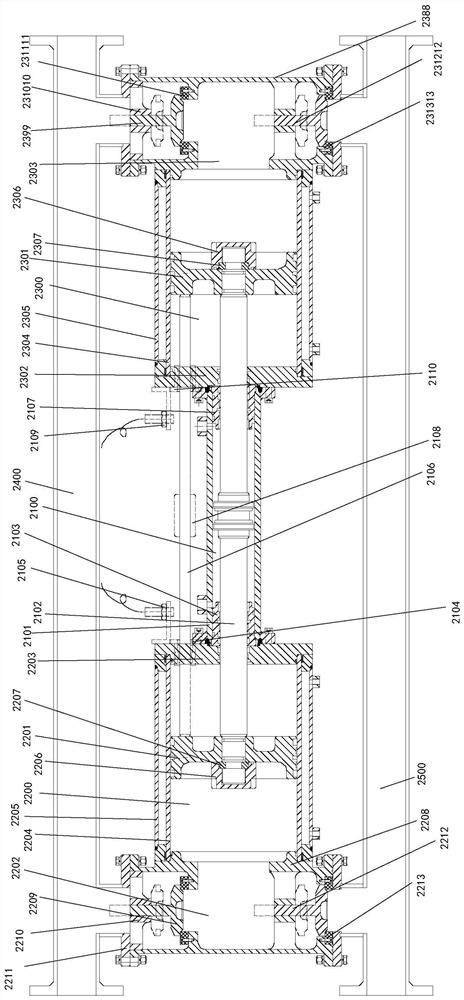

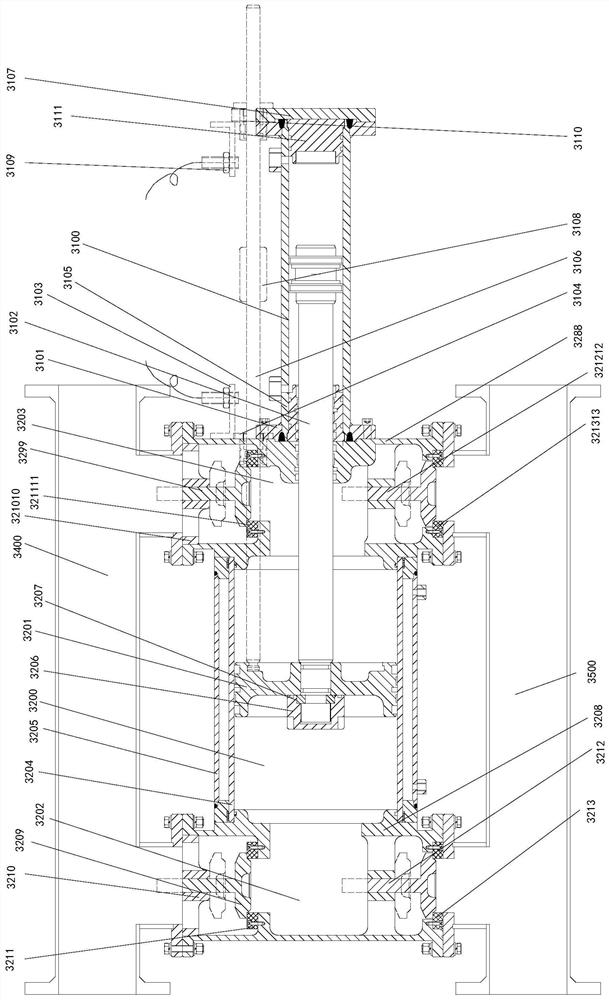

Main engine for oil drilling machine hydraulic hoister

PendingCN108678689AUniform spanDecrease the declinationDrilling rodsDrilling casingsHydraulic cylinderOil drilling

The invention discloses a main engine for an oil drilling machine hydraulic hoister. The engine comprises a hydraulic cylinder body and a hydraulic cylinder piston rod, the outer wall of the hydrauliccylinder body is provided with a fixed pulley block, the outer side of the fixed pulley block is provided with a lower retaining rope cover, the top end of the hydraulic cylinder piston rod is provided with a movable pulley block, the outer side of the movable pulley block is provided with an upper retaining rope cover, the top of the movable pulley block is provided with a locknut, the lower portion of the hydraulic cylinder body is provided with a hydraulic valve block, and the bottom end of the hydraulic cylinder body is provided with a single ear plate. The main engine is provided with the movable and fixed pulley blocks, the central axis of the movable pulley block and the central axis of the fixed pulley block are perpendicular to each other, the movable pulley block and the fixed pulley block are respectively provided with pulleys of different diameters, so that the span is uniform when a steel wire rope penetrates through the pulleys, it is ensured that the deflection angle ofthe steel wire rope is reduced, the eccentric wear is effectively reduced, and the service life of the pulleys and the steel wire rope is prolonged.

Owner:廖恒伟

Speed-adjustable sheet-type engaged gear infinitely variable transmission

InactiveCN108895136ASolve technical problems with high wear and tearNot easy to wearGearingGear wheelEngineering

The invention discloses a speed-adjustable sheet-type engaged gear infinitely variable transmission in the technical field of mechanical transmission. The infinitely variable transmission comprises asupporting frame, a driving arc-shaped wheel and a driven arc-shaped wheel are rotatably connected on the supporting frame, an output end of a first external transmission device is in transmission connection with a driving gear, the driving gear is engaged with a driven gear, the driving arc-shaped wheel faces the driven arc-shaped wheel, a plurality of driving inserting grooves are formed in thedriving arc-shaped wheel, a plurality of driven inserting grooves are formed in the driven arc-shaped wheel, a plurality of connecting grooves are formed in a first roller and a second roller, the first roller and the second roller are connected with first elastic sheets and second elastic sheets through the connecting grooves, the first elastic sheets and the second elastic sheets have the same structures, the driving arc-shaped wheel is positioned between the first roller and the second roller, at least one elastic sheet on the first roller and at least one elastic sheet on the second rollerare inserted into the driving inserting grooves and the driven inserting grooves, and corresponding arc-shaped buses of the peripheries of the driving arc-shaped wheel and the driven arc-shaped wheelare positioned on the same circle. A transmission part of the device is safe and reliable and not easy to abrade.

Owner:YANGZHOU UNIV

Gear case of high-speed trains and monitoring system for high-speed trains

PendingCN106871987AAvoid problemsSmooth transmissionThermometer detailsFlow propertiesLubricationHigh speed train

The invention provides a gear case of high-speed trains and a monitoring system for high-speed trains, wherein the gear case of high-speed trains includes a case, a monitoring device for lubrication oil and a collecting card for oil condition. The collecting card for oil condition is installed on the case. The monitoring device for lubrication oil includes a monitoring unit for oil quality, which is used to test quality of the lubrication oil in a detection box, is installed on the case and is connected with the collecting card for oil condition in communication. Once there are problems in the lubrication oil in the gear case, operating personnel can know the problems occurred in the gear case according to the condition of the lubrication oil, find reasons in time and get corresponding solutions to avoid problems of high-speed trains in operating and to prepare against possible calamities. Therefore, smoothness, security and reliability of driving, stability of high-speed trains, and life and property security of passengers are guaranteed.

Owner:CRRC CHANGCHUN RAILWAY VEHICLES CO LTD +1

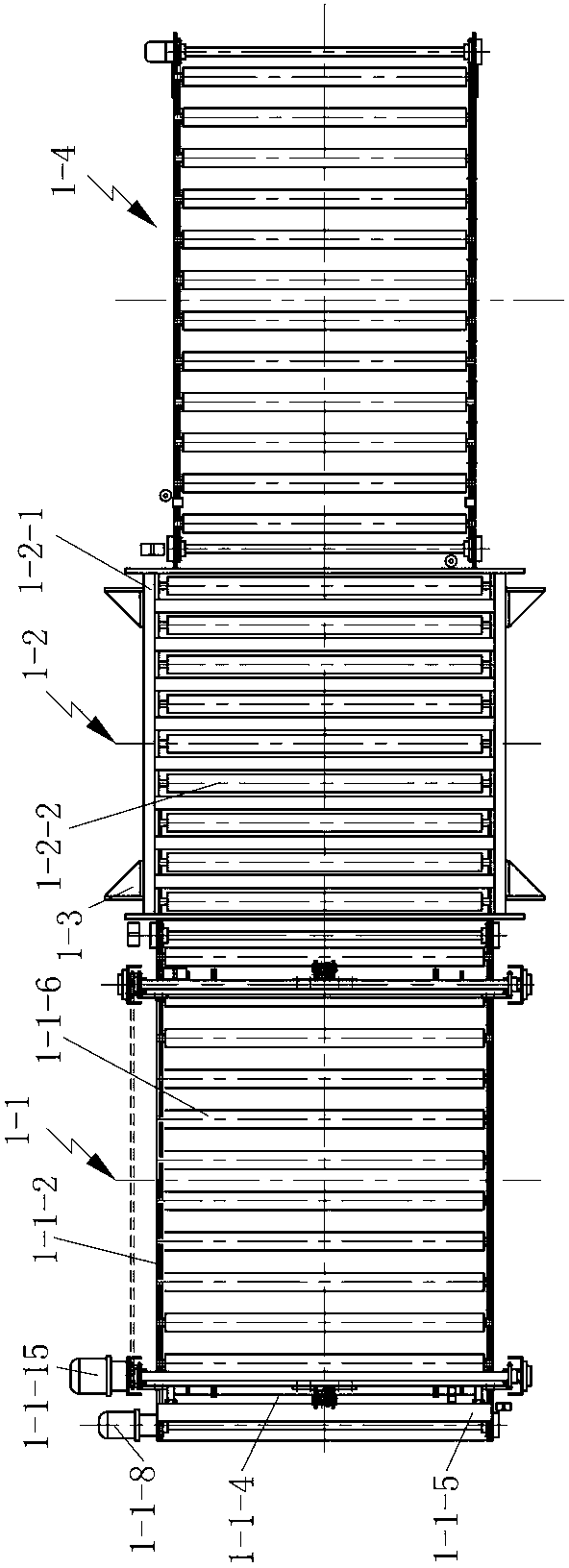

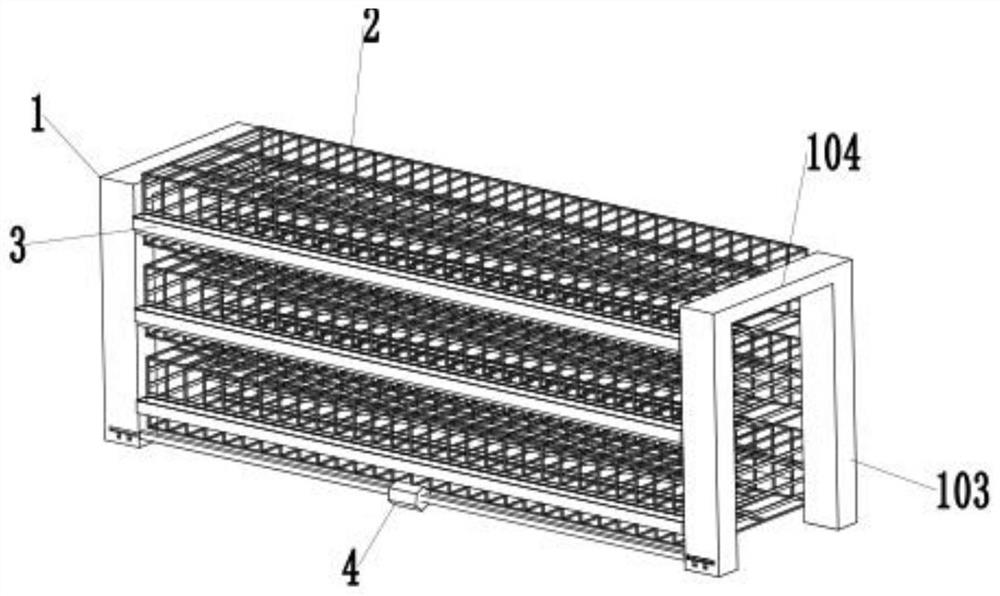

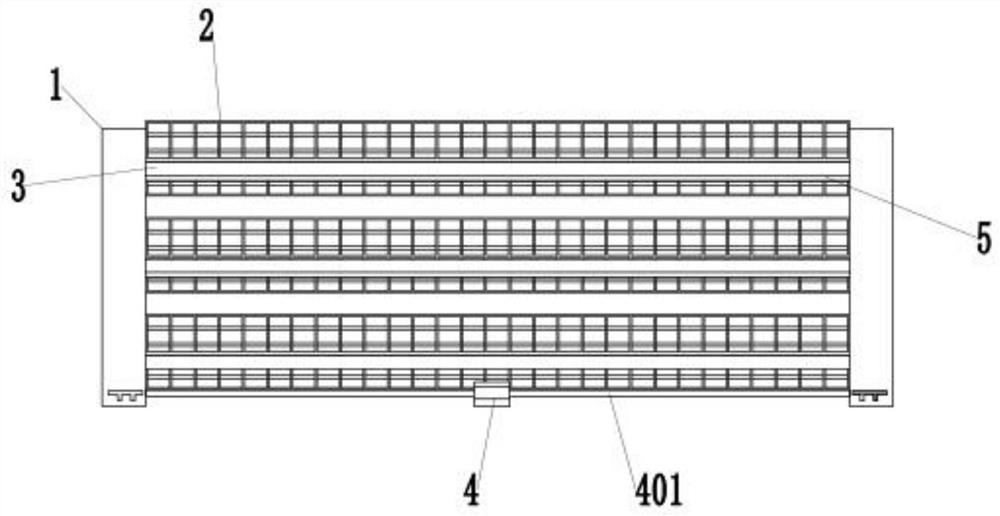

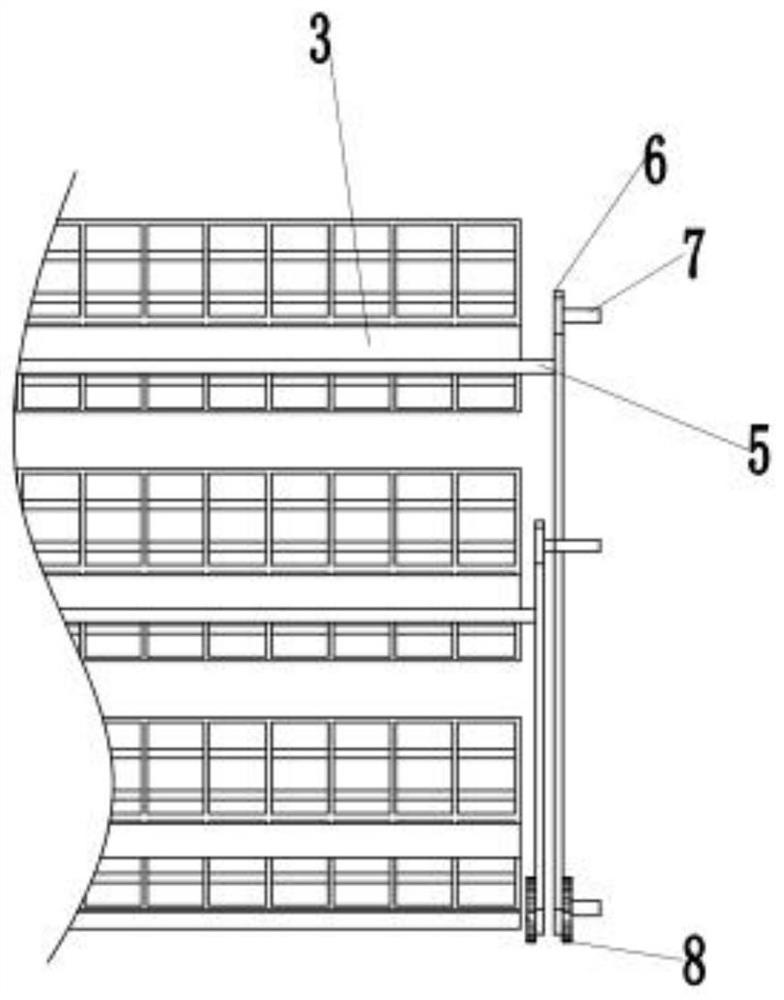

H-shaped stacked group-transferring coop

ActiveCN111990284AAvoid dangerSolve the problem of difficult to add feedBird housingsDrive wheelElectric machinery

Owner:SHANDONG YUKOU POULTRY

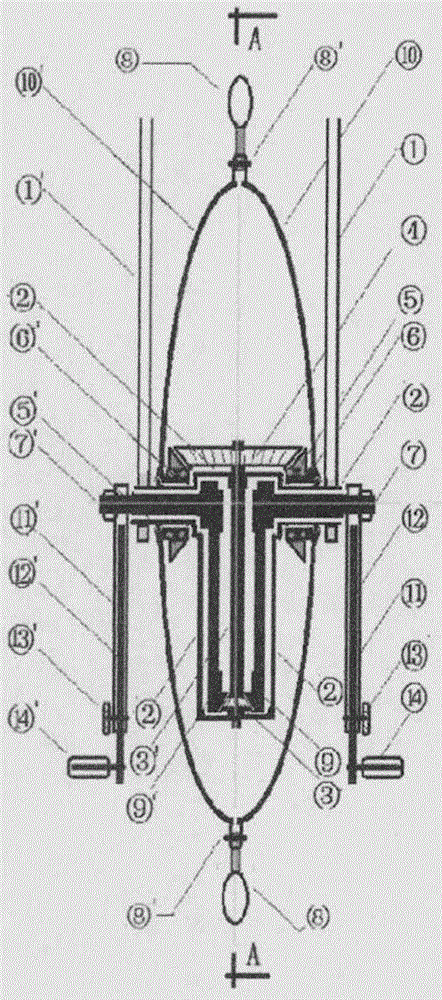

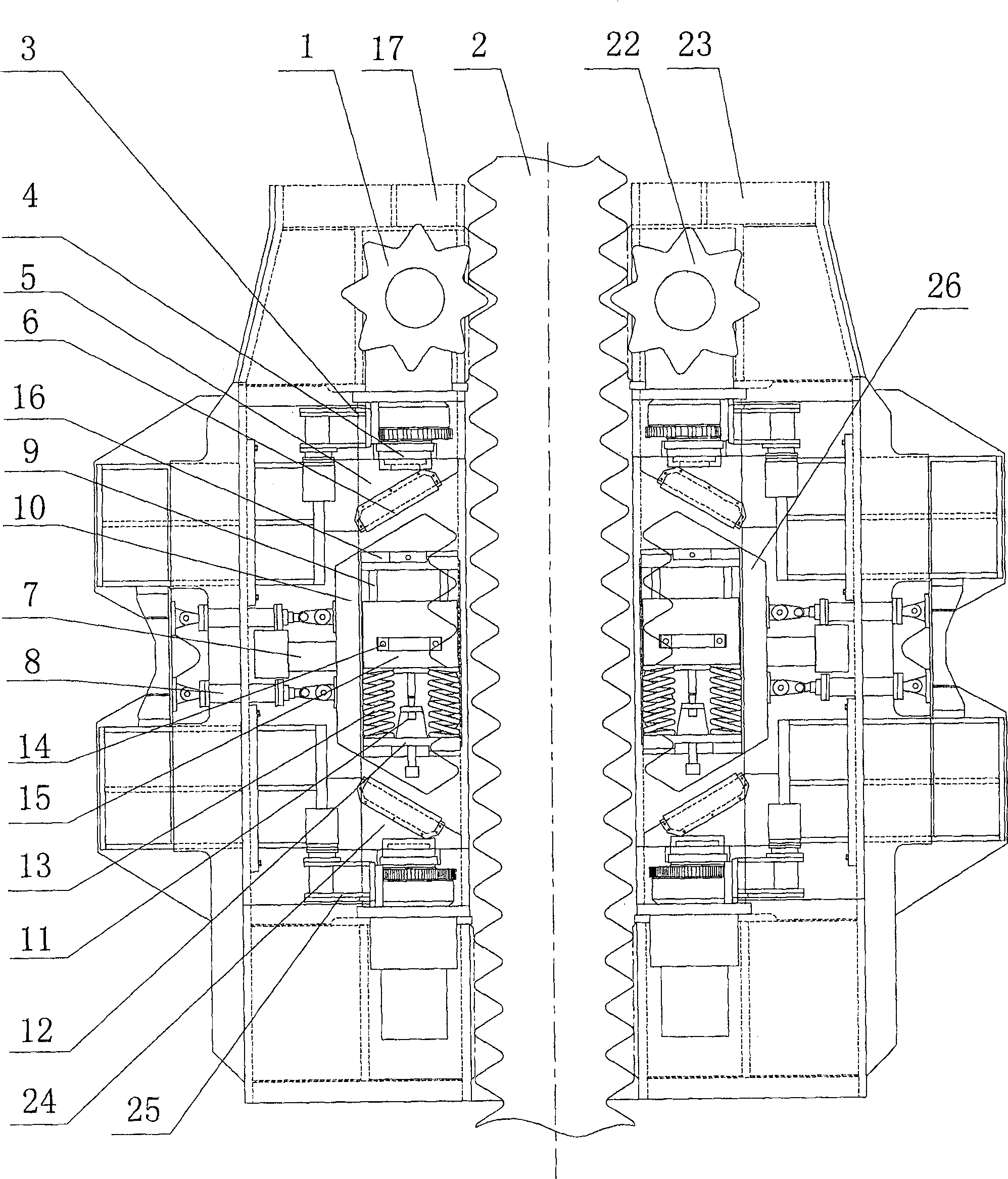

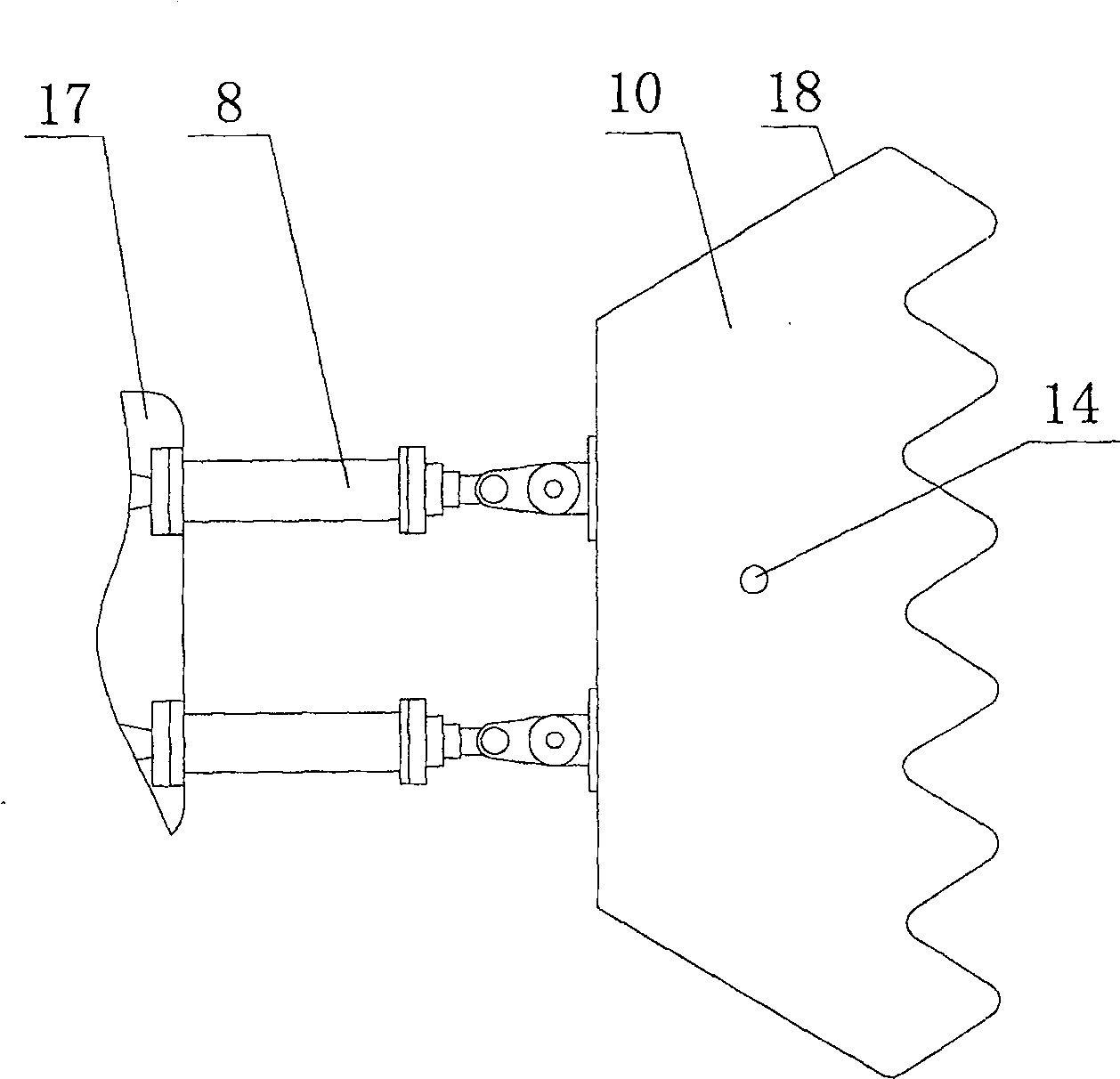

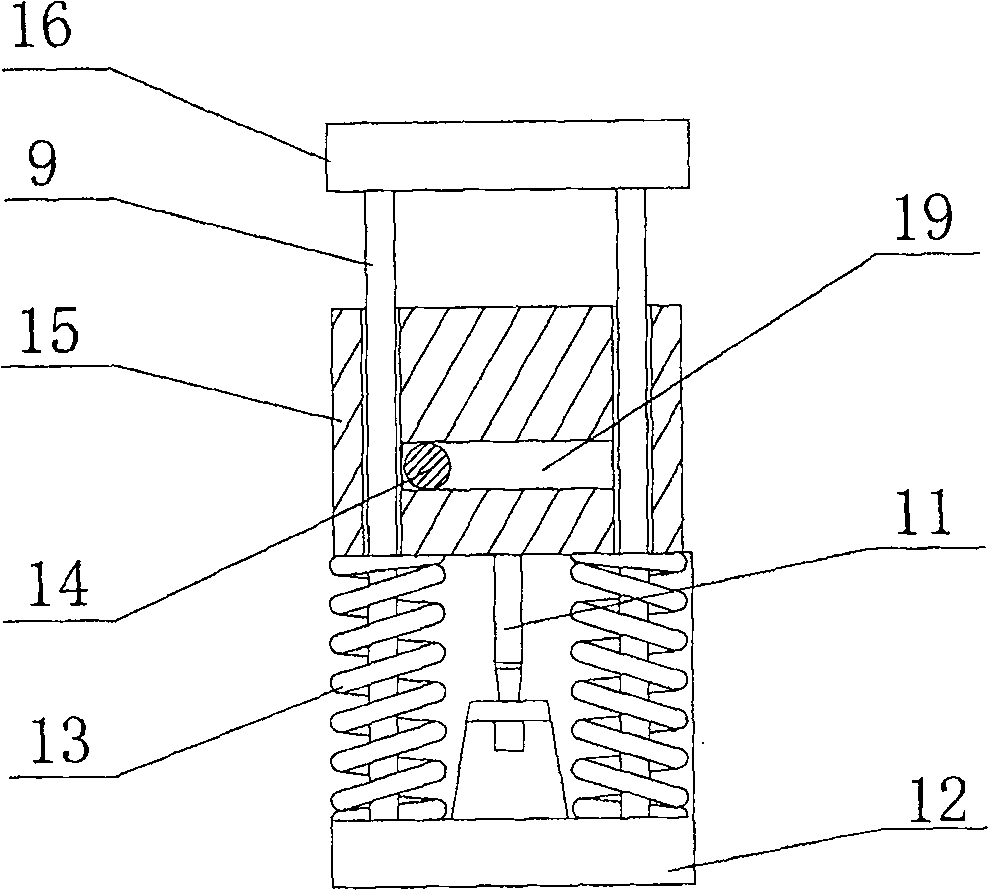

Vertical lifting and locking device

The invention relates to a lifting and locking device. The vertical lifting and locking device is composed of a vertical lifting mechanism and a locking mechanism, and is characterized in that the vertical lifting mechanism includes a fixed rack (2), a left lifting gear (1), a left motor, and a left bearing platform frame (17 ), the right lifting gear (22), the right motor, the right bearing platform frame (23), the left lifting gear (1) meshes with the teeth on the left end of the fixed rack (2), the right lifting gear (22) and the fixed gear The teeth on the right end of the bar (2) are meshed, the left lifting gear (1) is connected with the output shaft of the left motor, the right lifting gear (22) is connected with the output shaft of the right motor, and the left motor is fixed on the left bearing platform frame (17), the right motor is fixed on the right bearing platform frame (23), and the left bearing platform frame (17), the right bearing platform frame (23) are connected with the bearing platform respectively; locking mechanism. The invention has the characteristics of large carrying weight, high working efficiency, safety and reliability in static state.

Owner:陈定方 +5

Traction device for large structure crash test

ActiveCN107576469BTimely releaseAvoid damageVehicle testingShock testingScale structureLocking mechanism

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

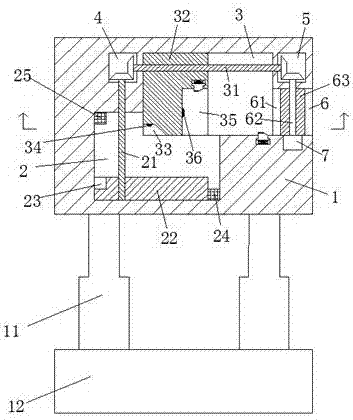

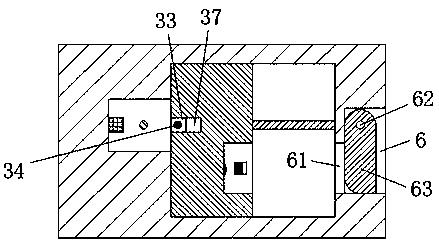

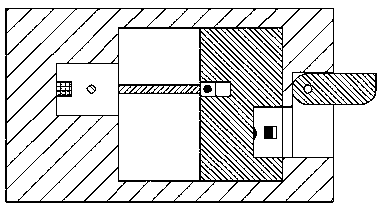

Charging device for circuit breaker hydraulic operating mechanism

ActiveCN106952754BSmall diameterSafe and reliable transmissionSwitch power arrangementsServometer circuitsMotor driveHigh pressure

Owner:西安西电高压开关操动机构有限责任公司 +1

An environmental protection dust removal facility

ActiveCN107204548BSafe and reliable transmissionSmooth transmissionCoupling device engaging/disengagingCoupling device detailsEngineering

Owner:JIANGSU XINPENG HEAVY ELECTROMECHANICAL MFG

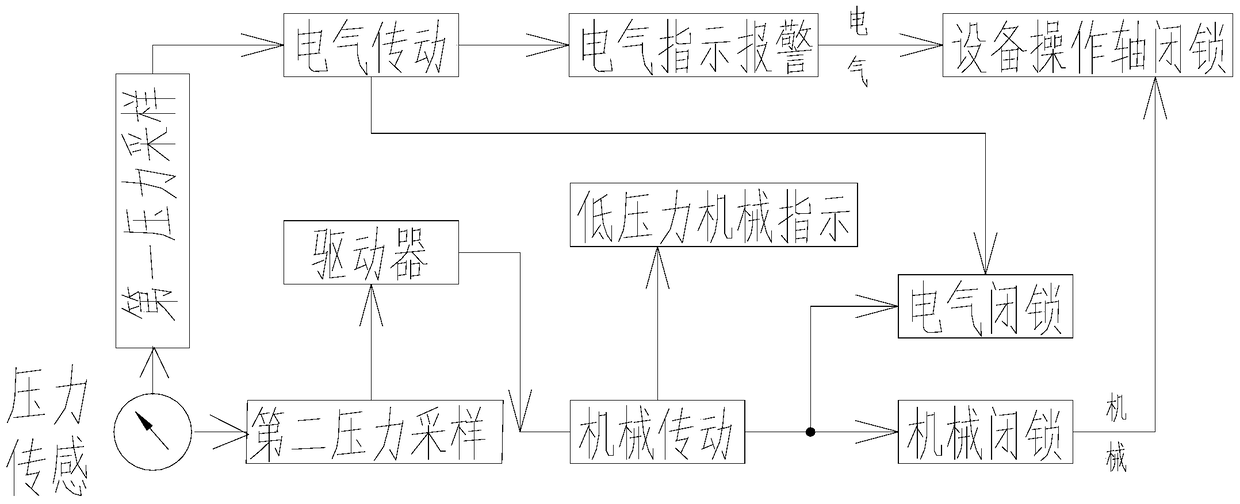

A c-gis low air pressure alarm locking device

ActiveCN105356423BSimple structureSmooth transmissionEmergency protective arrangements for automatic disconnectionInformation technology support systemOperating instructionPressure sense

Owner:ZHUHAI KELI ELECTRIC +1

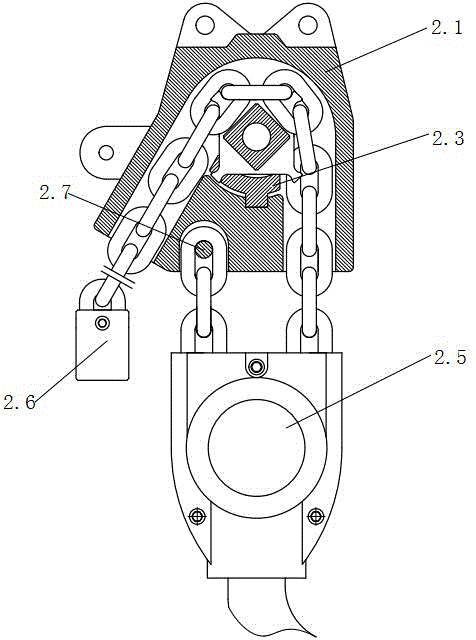

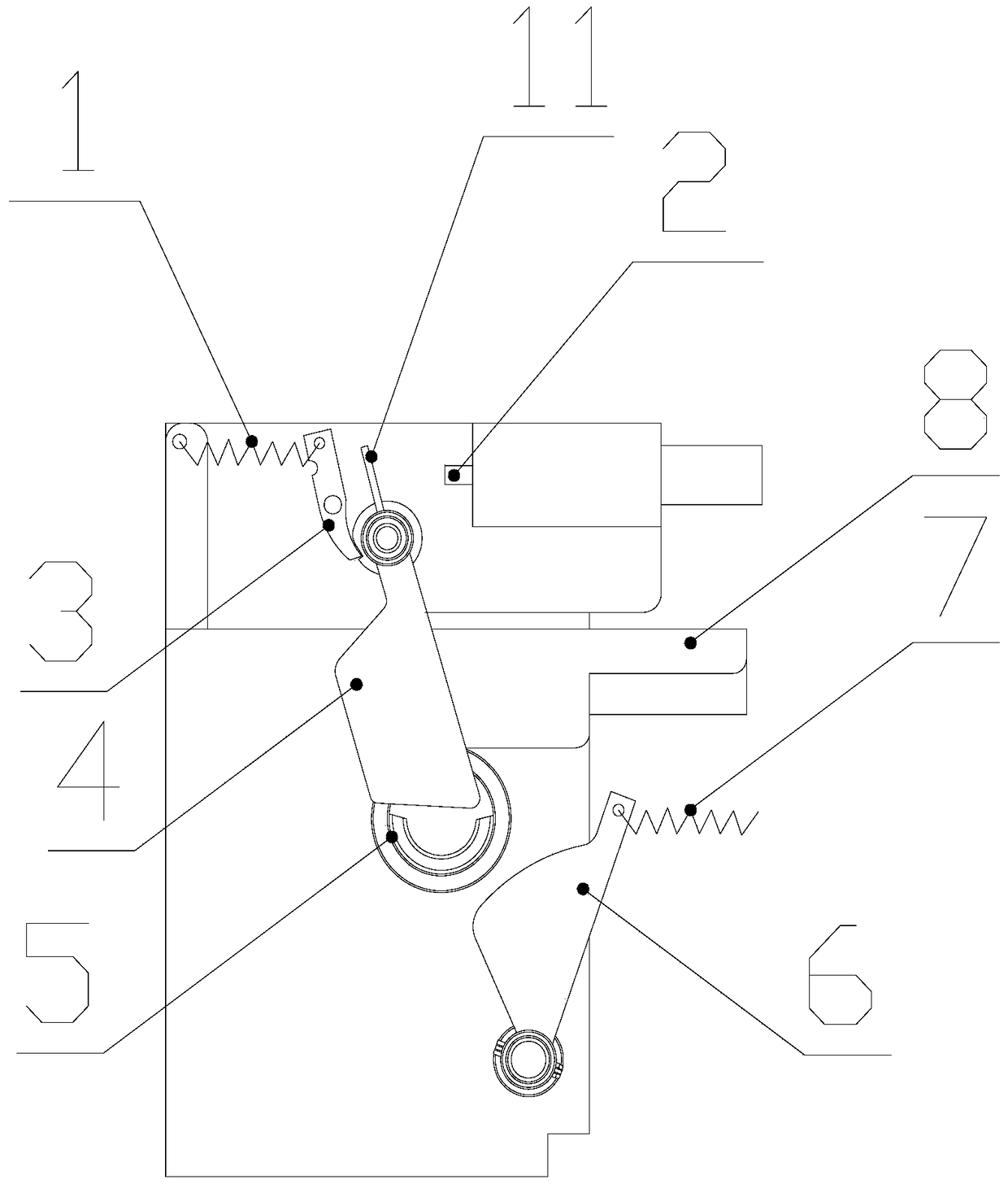

Traction device for large-scale structure collision test

ActiveCN107576469ATimely releaseAvoid damageVehicle testingShock testingScale structureLocking mechanism

The invention relates to large-scale structure collision test equipment, in particular to a traction device for large-scale structure collision test. The traction device comprises a traction body, a clamping mechanism connected with a transmission steel rope is arranged on the lower side of the traction body, a traction hook connected with the large-scale structure and a locking mechanism capableof locking the traction hook are arranged on the upper side of the traction body, the locking mechanism is used for locking the traction hook, and meanwhile, the clamping mechanism can clamp the transmission steel rope, the locking mechanism is used for unlocking the traction hook, and meanwhile the clamping mechanism can release the transmission steel rope. According to the locking mechanism, thetraction hook can be locked or unlocked, so that the safe and firm traction of the large-scale structure can be ensured, and the large-scale structure can be timely released; and moreover, when the locking mechanism locks or unlocks the traction hook, and the power transmission between the transmission steel rope and the traction device can be clamped or cut off, so that the transmission is safeand reliable, and the damage of the traction device can be reduced.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Piston Link Mechanism

ActiveCN111140565BImprove bearing capacitySafe and reliable transmissionFluid-pressure actuator testingServomotor componentsThermodynamicsSludge

The invention provides a piston linkage mechanism, which comprises a sludge cylinder piston, a double-acting hydraulic oil cylinder piston rod, a sludge cylinder key and a sludge cylinder key self-locking nut, the sludge cylinder piston and the double The piston rod of the hydraulic oil cylinder is fixed axially and radially by the sludge cylinder key, and the sludge cylinder key is axially locked and sealed by the self-sealing nut.

Owner:江苏万川液压机械设备有限公司

Coater as well as scraping and wiping apparatus thereof

ActiveCN108037635APrevent splashGuaranteed wiping effectLiquid surface applicatorsPhotomechanical coating apparatusIsolation effectEngineering

The invention discloses a scraping and wiping apparatus for a coater. The apparatus comprises the following components: a scraping and wiping base; a driving motor which is arranged in a blocking chamber for driving the scraping and wiping base, wherein the driving motor and the scraping and wiping base are connected through a connecting rod, and the blocking chamber comprises an accommodating zone for installing the driving motor and a blocking zone which is arranged between the scraping and wiping base and the accommodating zone, the blocking zone and the accommodating zone are communicated,and the blocking zone is used for separating a working zone where the scraping and wiping base exists and the accommodating zone. The invention also discloses the coater. The coater as well as the scraping and wiping apparatus can enhance isolation effects, effectively avoids splashing of photoresist to a driving source, so that scraping and wiping effects as well as normal working of equipment are guaranteed; the structure is simple and concise, transmission is safe and reliable, and maintenance is facilitated.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com