Material level control system, control method and water treatment tank

A control system and material level technology, applied in the direction of control/regulation system, control/manipulation system, liquid level control, etc., can solve the problems of substandard, unsatisfactory judgment of material level accuracy, waste of water resources and water quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0036] In the following description of the water treatment tank, only the structure closely related to the present invention will be described. For other structures in the water treatment system, such as the dosing device, the sedimentation device placed in the sedimentation tank, etc., those skilled in the art can refer to the current There is technology to implement it. In the water treatment system, at least the flocculation tank and the sedimentation tank need to be discharged. The level control system of the present invention can be used in the flocculation tank and / or the sedimentation tank, and can also be used in other tanks that need to be discharged. The sludge discharge of the sedimentation tank is taken as an example to illustrate.

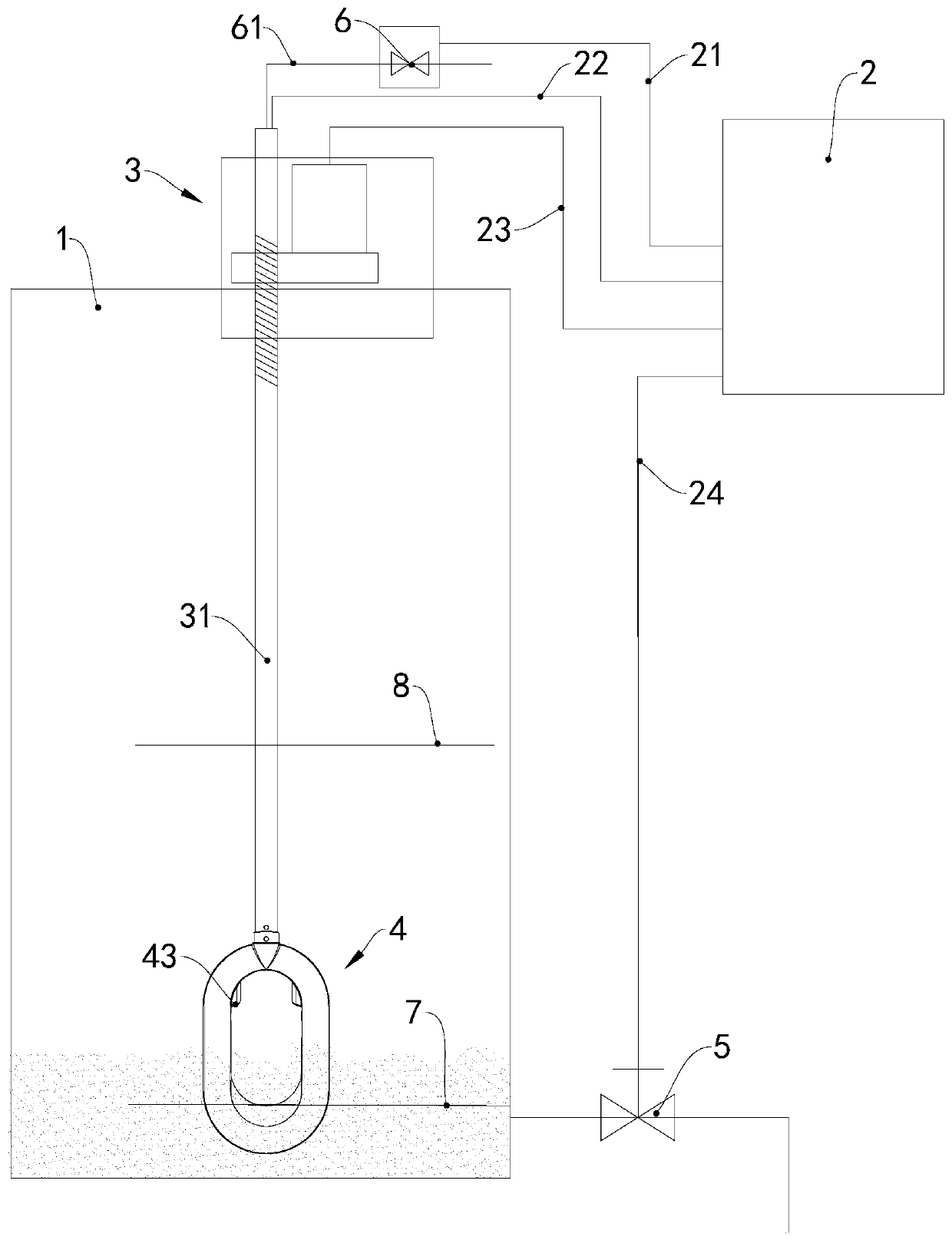

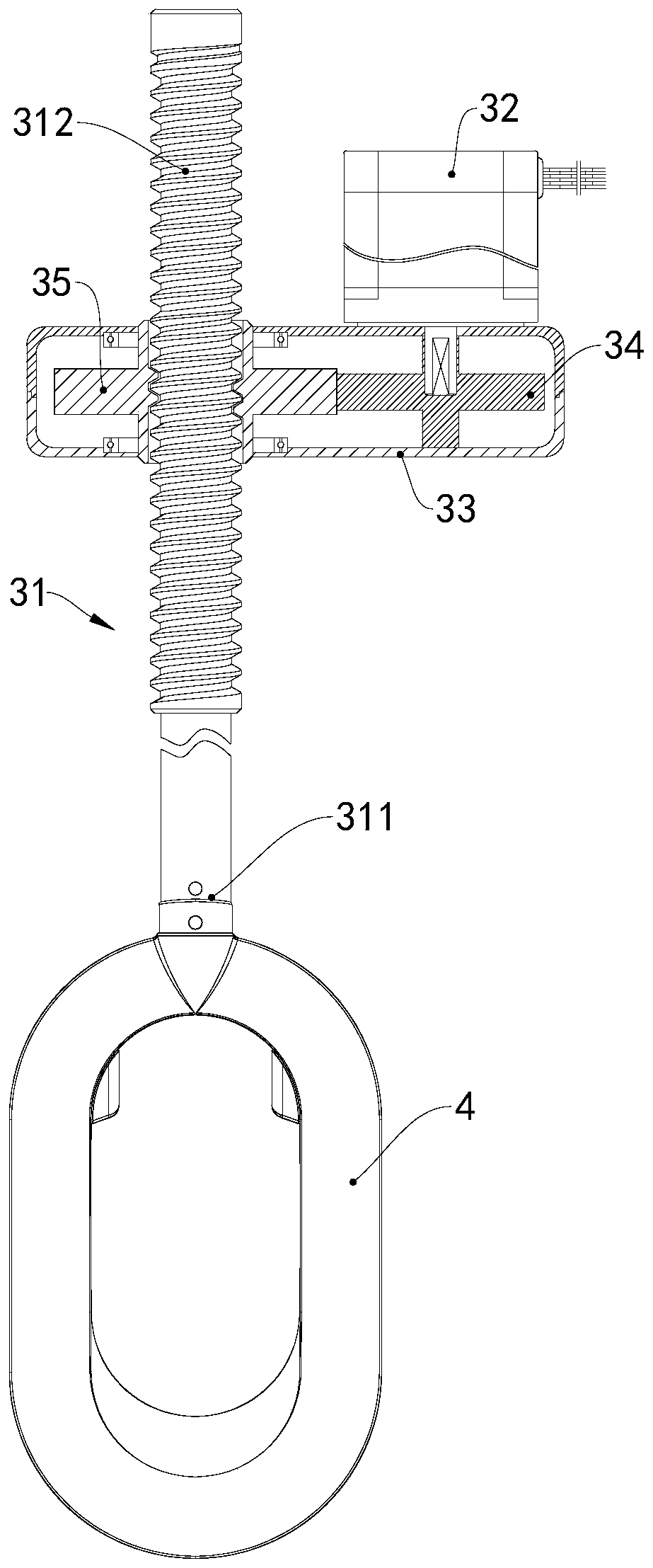

[0037] see figure 1 , the water treatment tank has a sedimentation area 1 and a level control system, the level control system has a control unit 2, a lifting device 3, a detection unit 4, a mud valve 5 and an air valve 6, and the lif...

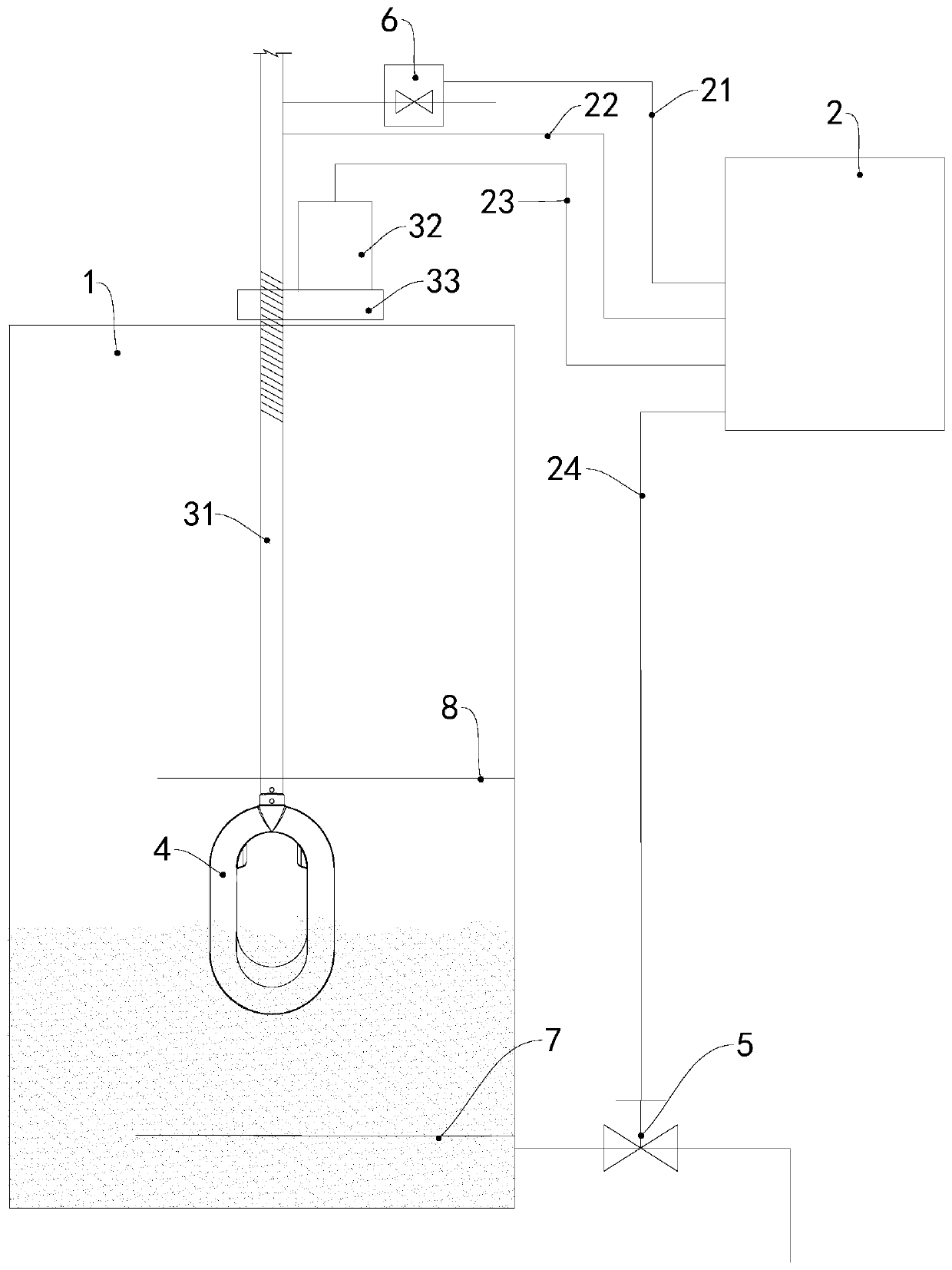

no. 2 example

[0045] see Figure 4 and Figure 5 , Figure 5 yes Figure 4 , and the detection unit 4 is omitted. The difference between this example and the previous example is the structure of the lifting device 3 in the level control system. The upper section of the lifting rod 31 is a rack 313, and a stepper The motor 36 drives the reduction box 33.

no. 3 example

[0047] see Figure 6 and Figure 7 , Figure 7 yes Figure 6 The left side view of , and omit the detection unit 4 and the stepping motor 36, the difference between this example and the first example is also the structure of the lifting device 3 in the level control system, the upper section of the lifting rod 31 is a worm 314, which adopts A stepping motor 36 drives the worm gear 37, and the lifting rod 31 is driven by the worm gear 37 to lift.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com