Mine vehicle-mounted hydraulic winch

A hydraulic winch, vehicle-mounted technology, applied in hoisting devices, clockwork mechanisms, etc., can solve the problems of inconvenient material or mechanical equipment transportation, inflexible operation methods, and affecting production efficiency, and achieve compact structure and braking effect Good, simple and practical braking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific embodiment of the present invention will be further described in conjunction with the accompanying drawings.

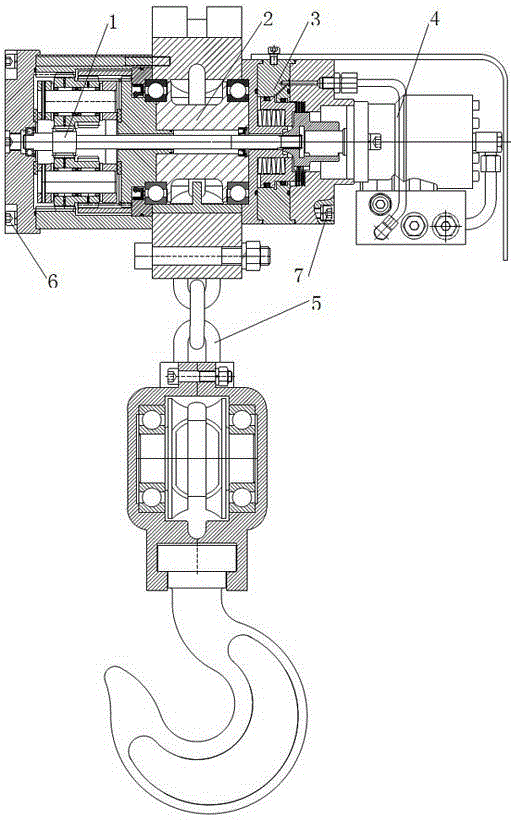

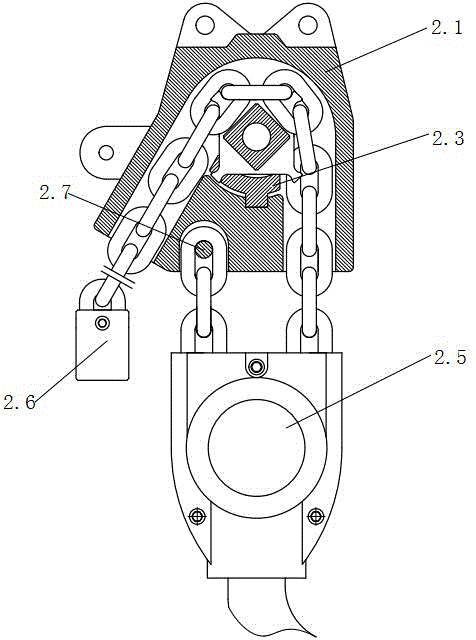

[0029] The main structure of the present invention is composed of a planetary reducer 1, a chain winding mechanism 2, a brake 3, a hydraulic motor assembly 4, a circular chain 5 and the like. The planetary reducer 1 and the winding chain mechanism 2 are axially matched through the bearing end cover 1.14, and are connected through the hexagon socket bolt 6; on the other side, the brake is fixedly connected with the winding chain mechanism 2 through the socket bolt 7; the hydraulic motor assembly 4 is installed On the motor fixing block 3.4, it is fixed by the hexagon socket bolt 4.1; the circular link chain 5 is the carrier of the transmission output, and under the drive of the circular link chain sprocket 2.2, it drives the hook assembly to realize the lifting or putting down of the heavy object.

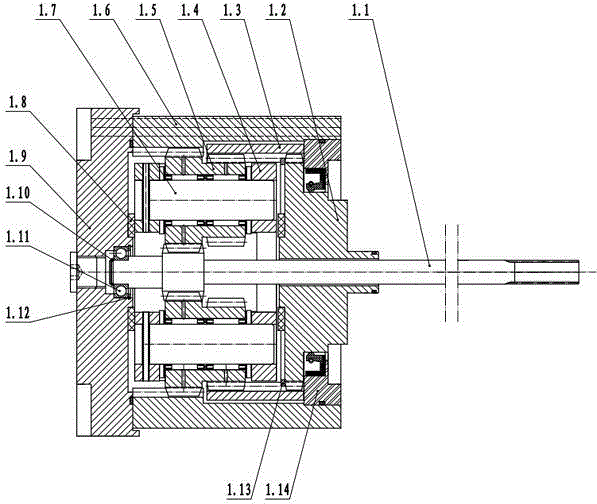

[0030] The planetary reducer includes a main shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com